- Product Details

- {{item.text}}

Quick Details

-

Ejector Force(kN):

-

43 kN

-

Theoretical Shot Volume(cm³):

-

300 cm³

-

Injection Rate (g/s):

-

30 g/s

-

Injection Weight (g):

-

165 g

-

Screw diameter (mm):

-

150 mm

-

Distance between Tie Bars:

-

150mm

-

Weight (KG):

-

5200

-

Place of Origin:

-

Guangdong, China

-

Open Stroke(mm):

-

550 mm

-

Power (kW):

-

12.1 kW

-

Plastic Type:

-

Thermosetting

-

Automatic:

-

yes

-

Machine Color:

-

Green and white

-

Machine dimension(L*W*H):

-

4.1x1.6x2.0mm

-

Pump Pressure:

-

21Mpa

-

Voltage:

-

380V/220/415V

-

Feature:

-

Multi-function Operation System

-

Operating Language:

-

multi language

-

MAX mold height:

-

700mm

-

Used for:

-

Making menstrual cup

-

Certification:

-

CE, ISO9001

-

Marketing Type:

-

New Product 2021

Quick Details

-

Distance between Tie Bars(Width)(mm):

-

450mm

-

Distance between Tie Bars(Height)(mm):

-

450mm

-

Ejector Stroke(mm):

-

150 mm

-

Ejector Force(kN):

-

43 kN

-

Theoretical Shot Volume(cm³):

-

300 cm³

-

Injection Rate (g/s):

-

30 g/s

-

Injection Weight (g):

-

165 g

-

Screw diameter (mm):

-

150 mm

-

Distance between Tie Bars:

-

150mm

-

Weight (KG):

-

5200

-

Place of Origin:

-

Guangdong, China

-

Open Stroke(mm):

-

550 mm

-

Power (kW):

-

12.1 kW

-

Plastic Type:

-

Thermosetting

-

Automatic:

-

yes

-

Machine Color:

-

Green and white

-

Machine dimension(L*W*H):

-

4.1x1.6x2.0mm

-

Pump Pressure:

-

21Mpa

-

Voltage:

-

380V/220/415V

-

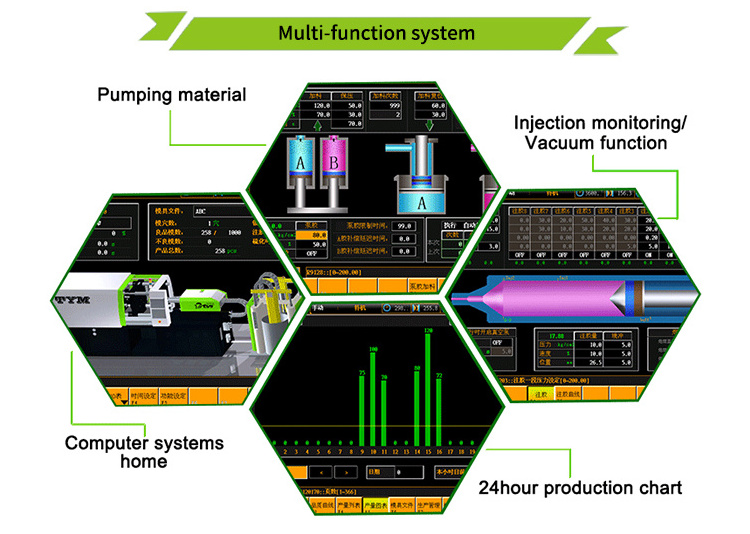

Feature:

-

Multi-function Operation System

-

Operating Language:

-

multi language

-

MAX mold height:

-

700mm

-

Used for:

-

Making menstrual cup

-

Certification:

-

CE, ISO9001

-

Marketing Type:

-

New Product 2021

Automatic Energy-Saving Ambu Bag LSR Injection Molding

Horizontal Liquid Silicone Rubber (LSR) injection molding machine

D irect pressure mould opening and closing system, horizontal injection structure, it can adjust the mould faster, and control the position more precisely. I t is more suitable for producing the LSR parts which can be automatically remo ved from the mould.

The main feature of TYM vertical LSR molding machine:

1.N ewly-optimized integrated all-in-one design.

2.Meet multiple requirements on the automatic manufacturing technique for LSR products.

3.Shorter the mould closing and opening time, improve the production efficiency.

4.Active pin valve-pattern nozzle sealing system, which can guarantee the injection more accurately.

5.Multi-section mould closing and opening and injection, speed adjusting stepless.

6.High-performance servo motor system is installed, which can guarantee the machine work more accurately and more energy-saving.

7. Adopts the international brand component for keeping machine running stable, reliable and accurately.

8. User-friendly LCD display which owns diverse languages system indicates various functions and working situation.

9. TYM horizontal injection machine have the advantage of low noise, low energy consumption,high efficiency and long life time.

Mechanical Characteristics for TYM-W4545

|

TYM-W4545 Horizontal LSR injection molding machine |

|

|

Injection Unit |

|

|

Shot Volume |

165 g |

|

Injection Rate |

30 g/s |

|

Injection Pressure |

19.6 T |

|

Clamping Unit |

|

|

Clamping Force |

130 T |

|

Opening Stroke |

200-700 mm |

|

Tie-Bars Space |

450*450mm |

|

Ejection Force |

7.8 T |

|

Ejection Stroke |

150 mm |

|

Others |

|

|

Pump Pressure |

21 Mpa |

|

Motor Power |

11KW |

|

Heater Power |

9 KW |

|

Mould Orientation Ring Diameter |

Φ 100 mm |

|

Machine Weight |

5.2T |

|

Machine Dimension |

4.0*1.2*2.0 m |

|

LSR feeding machine Dimension |

1.2*1.2*2.0m |

One-stop complete solution

" raw material + liquid silicone injection molding machine + mold + technical support + personnel training + finished products ”

1. Provide considerate suggestion to choose suitable material with low cost high-performance.

2. Help customer make mold design , manufactur ing and testing .

3. According to customer's demand, supply machine solution,including whole produce line.

4. Correctly guide customer to operate machine by video or on-site training.

5.H elp client purchase essential accessory .

Application:

TYM injection molding machine is suitable for multi-purpose silicone rubber molding. Our LSR injection machines have been widely used in medical industry, food industry, auto industry, infant industry, electronics industry, diving industry and so on.

TYM have s pecialized in liquid silicone for more than 1 8 years , we got more than 60 patents ,including 12 invention patents . TYM has rated as a national high-tech enterprise in 2013 . Also , TYM horizontal machine has got the gold award of international exhibition invention.

we had sold the machines as well as the products to more than 30 countries all over the world.