Name: Decoiler

Brand:China own made

Capacity: 5 tons

- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-1mm or as your requirement

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

KYT

-

Voltage:

-

380V 50 Hz 3 phases

-

Dimension(L*W*H):

-

8.5*1.65*1.5m

-

Weight:

-

6500 kg

-

Feeding width:

-

as your requirement

-

Marketing Type:

-

New Product 2024

-

Form Tolerance:

-

±0.5mm

Quick Details

-

Type:

-

cold roll forming machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

20M/MIN

-

Rolling thinckness:

-

0.3-1mm or as your requirement

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

KYT

-

Voltage:

-

380V 50 Hz 3 phases

-

Dimension(L*W*H):

-

8.5*1.65*1.5m

-

Weight:

-

6500 kg

-

Feeding width:

-

as your requirement

-

Marketing Type:

-

New Product 2024

-

Form Tolerance:

-

±0.5mm

Product Description

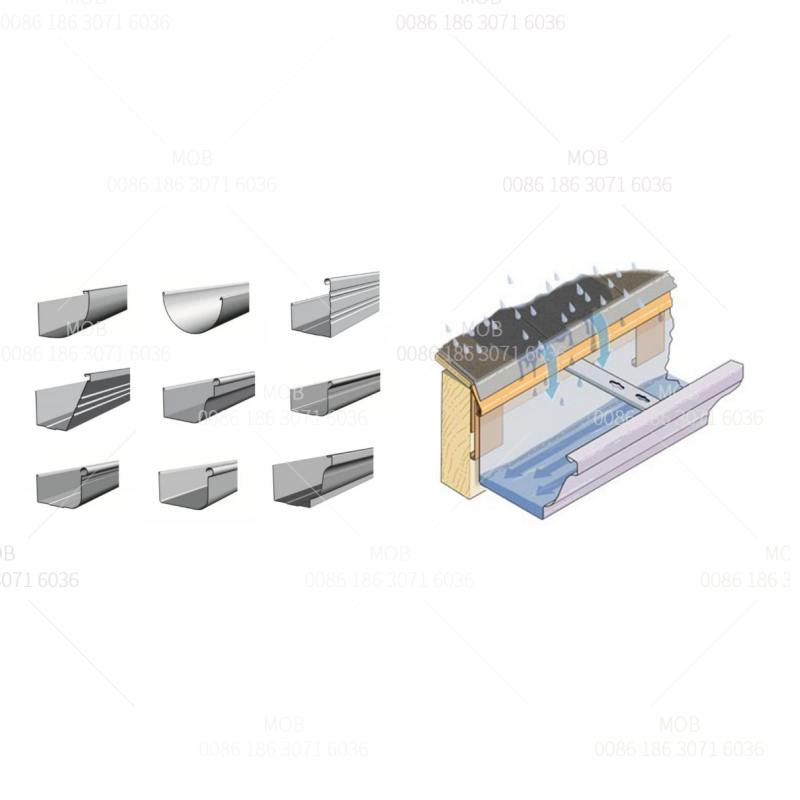

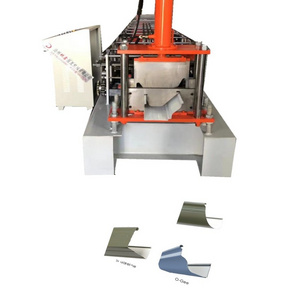

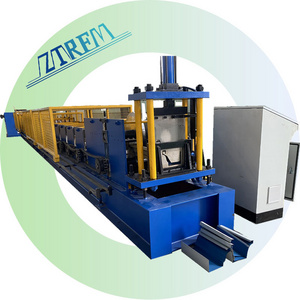

Customized rain gutter downpipe cold bending forming machine

1. The whole machine is controlled by PLC, and multiple safety protections can be set to effectively avoid accidents;

4. The roll shaft is made of 45# steel, which has been quenched and tempered;

5. The material of forming punching and shearing die is Gr12.

2. The bed is made of steel plate welded parts and tempered to effectively eliminate internal stress and the body is not easy to deform;

3. The forming frame is welded by channel steel;

4. The roll shaft is made of 45# steel, which has been quenched and tempered;

5. The material of forming punching and shearing die is Gr12.

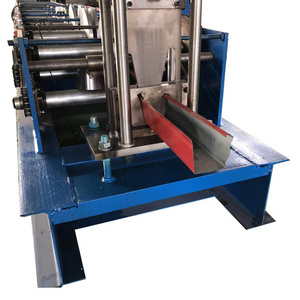

Machine Parts

Name: Main forming system

1. Rollers adopt Cr12,surface chrome 0.03-0.05mm,Hard chrome mirror polishing, ensure roller smooth.Spacers must lathe inner holes, and do Chrome plating;

2. Transfer method adopts gear.

Machine Parts

Control system

Delta touch screen, Delta frenqucy inveter.

Machine Parts

Roller chrome coated thickness: 0.05 mm

Roller material: Forging Steel 45# heat treatment.

Machine Parts

Feeding platform

Machine Parts

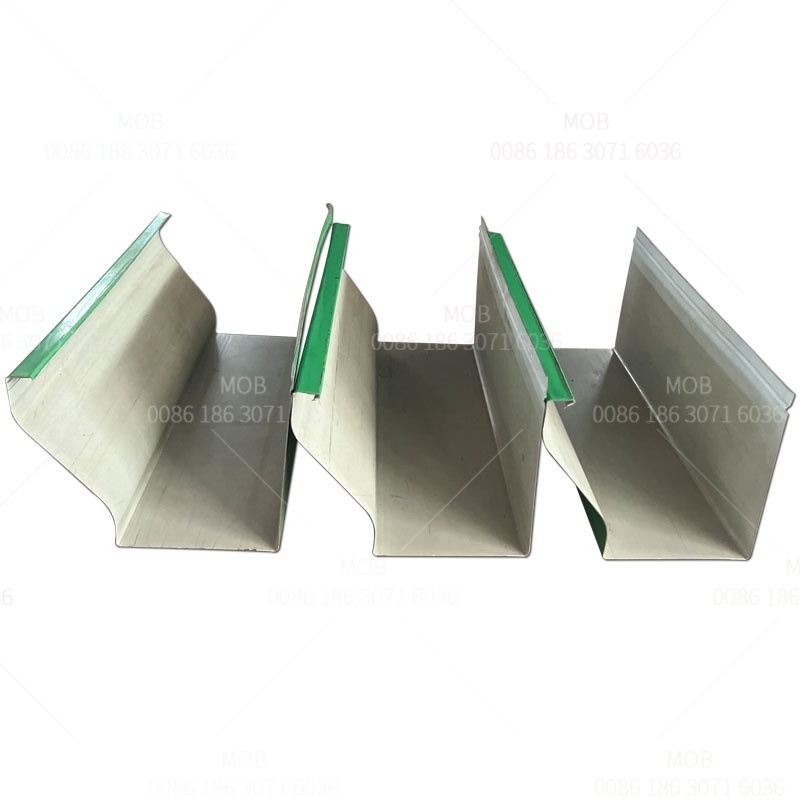

Finished product display

Specification

|

Suitable Material

|

Color Steel, Galvanized Steel

|

|

Raw material width

|

According to customer needs

|

|

Material thickness

|

0.3-0.8 mm or customized

|

|

Voltage

|

380v 60hz or Customized

|

Application

1 The execution of production orders is more efficient and accurate;

2. The equipment has high reliability;

3. Less waste of materials and energy;

4. High productivity;

5. High-quality materials for longer service life;

6. All parts of the machine are precision machined, and the surface of the roller is chromium-plated to ensure that customers receive qualified products while avoiding scratches on the paint on the color steel surface and extending the service life;

7. Customize coil processing solutions to solve various technical problems.

All control systems of our machines are manufactured by ourselves. We have professional engineers to design and make control systems. This ensures after-sales service, and when customers have control problems, we can solve them in time.

Packing&Shipping

1.We will wipe anti rust oil for the whole machine .

2.Plc controller will be covered by foam film.

2.Plc controller will be covered by foam film.

3.Spare parts are some small parts are packed in a wodden case.

4.All componenets are fixed well by steel wire with container.

4.All componenets are fixed well by steel wire with container.

Choose product

Company Introduction

FAQ

Q1: Are you a manufacturer?

A1:Yes, we are professional manufacturer of the roll forming machine

Q2. What are the main key points for selecting right machines?

A2: Whole structure,Roller Shaft,Roller Material,Motor&Pump,and Control system. As the new buyer, please kindly know that price not the final point.Good quality is for long-term business cooperation.

Q3. Can you provide OEM service for roll forming machine?

A3: Yes, most of cold roll forming machine need to be customized as detailed request, because raw material , size , production usage, machine speed, then machine specification will be some different.

Q4. How about the after-sale service?

A4: We provide 5 years free warranty and free technical support for the whole life of any machine. During warranty period, if parts still broken, we can send the new ones freely.

Q5:I do not know about the machine and do not know how to install it. Can you install the machine in my factory?

A5: If you need us to send engineers to your factory, you will pay for the travel expense such as visa, round tickets, hotel, food Salary of 80 -100 USD per day per person (from departure from our factory, until we are back to our factory). You also need to take care of his safety.

Q6: I receive a lot of quotations, they are big range, How could i choose?

A6: I have many easy ways to solve it. Fox example, I can teach you how to find the Traders out. Just contact me. It is free for contacting with me.

Q7: I have not whatsapp and skype, how could I contact with you?

A7: Send me one inquiry in the end of this page. Leave your contact information for me. I will contact you. It is free.

Q8. If I am in Beijing,Shanghai or Guangzhou,how to visit your company?

A8: 1) Beiing South Statioin to Cangzhou West Station (by fast train 1 hour).

2) Shanghai Hongqiao to Cangzhou West (4.5 hours)

3) Guangzhou Airport to Tianjin ,then Tianjin to Cangzhou West

A1:Yes, we are professional manufacturer of the roll forming machine

Q2. What are the main key points for selecting right machines?

A2: Whole structure,Roller Shaft,Roller Material,Motor&Pump,and Control system. As the new buyer, please kindly know that price not the final point.Good quality is for long-term business cooperation.

Q3. Can you provide OEM service for roll forming machine?

A3: Yes, most of cold roll forming machine need to be customized as detailed request, because raw material , size , production usage, machine speed, then machine specification will be some different.

Q4. How about the after-sale service?

A4: We provide 5 years free warranty and free technical support for the whole life of any machine. During warranty period, if parts still broken, we can send the new ones freely.

Q5:I do not know about the machine and do not know how to install it. Can you install the machine in my factory?

A5: If you need us to send engineers to your factory, you will pay for the travel expense such as visa, round tickets, hotel, food Salary of 80 -100 USD per day per person (from departure from our factory, until we are back to our factory). You also need to take care of his safety.

Q6: I receive a lot of quotations, they are big range, How could i choose?

A6: I have many easy ways to solve it. Fox example, I can teach you how to find the Traders out. Just contact me. It is free for contacting with me.

Q7: I have not whatsapp and skype, how could I contact with you?

A7: Send me one inquiry in the end of this page. Leave your contact information for me. I will contact you. It is free.

Q8. If I am in Beijing,Shanghai or Guangzhou,how to visit your company?

A8: 1) Beiing South Statioin to Cangzhou West Station (by fast train 1 hour).

2) Shanghai Hongqiao to Cangzhou West (4.5 hours)

3) Guangzhou Airport to Tianjin ,then Tianjin to Cangzhou West

Hot Searches