- Product Details

- {{item.text}}

Quick Details

-

Thermal Conductivity:

-

0.13-0.19w/m.k(800-1000C)

-

Thickness:

-

3/10/80mm

-

Width:

-

1000/600/300mm

-

Length:

-

1200/1000/900/600mm

-

Working Temperature:

-

1050C

-

Shrinkage (1800℉, 3h):

-

-3%(24h)

-

Place of Origin:

-

Henan, China

-

Model Number:

-

XDEM-1260

-

Brand Name:

-

XDEM

-

Material:

-

99.70% Al2o3

-

The Ultra- thin of fiber board:

-

3-10mm

-

size:

-

customizable

-

Desnsity: g / cm3:

-

280-480kg/m3

-

compress strength:

-

0.3-0.7Mpa

Quick Details

-

Chemical Composition:

-

Al2O3 46%

-

Ultimate Strength (≥ MPa):

-

0.8-1.2Mpa

-

Fiber Diameter:

-

3-5μm

-

Thermal Conductivity:

-

0.13-0.19w/m.k(800-1000C)

-

Thickness:

-

3/10/80mm

-

Width:

-

1000/600/300mm

-

Length:

-

1200/1000/900/600mm

-

Working Temperature:

-

1050C

-

Shrinkage (1800℉, 3h):

-

-3%(24h)

-

Place of Origin:

-

Henan, China

-

Model Number:

-

XDEM-1260

-

Brand Name:

-

XDEM

-

Material:

-

99.70% Al2o3

-

The Ultra- thin of fiber board:

-

3-10mm

-

size:

-

customizable

-

Desnsity: g / cm3:

-

280-480kg/m3

-

compress strength:

-

0.3-0.7Mpa

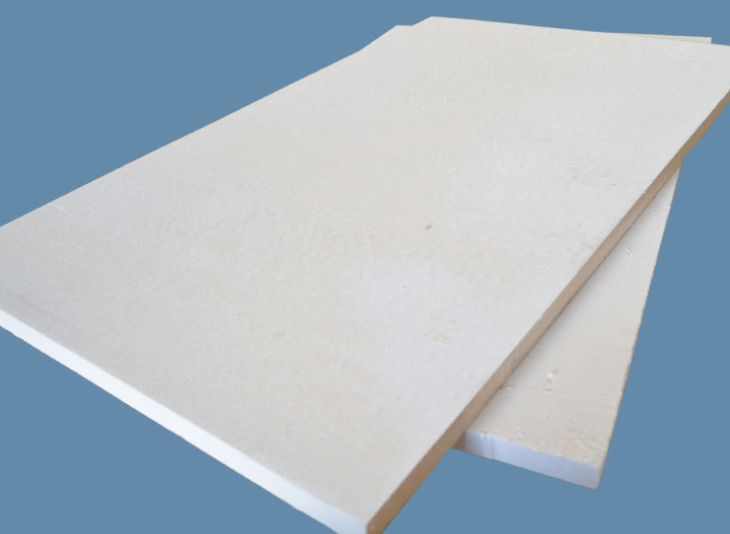

High density 1260 refractory ceramic fiber board for furnace

Ceramic Fiber Board is made through automation control and continuous production process, with a host of features such as precise size, good flatness, high compressive strength, lightweight, excellent thermal shock resistance and anti-stripping, which can be widely used for insulation in the linings around and at the bottom of kilns, as well as ceramic kilns fire position, craft glass mold and other positions.

| Characteristics | precise flatnessse size and excellet flatness, easy to instanll and to be cutted | |||||

| good fiber distribution | ||||||

| low heat capacity and low thermal conductivity | ||||||

| excellent chemical stability and thermal stablity | ||||||

| good thermal shock resistance | ||||||

| high compressive strength | ||||||

| non-brittle material, good elasticity | ||||||

| Application |

Industrial furnace wall lining and bricking-up insulation layer, which can be used in iron and steel furnace, lanunders & distribution pens

Non ferrous metal industry, Ceramic industry, Glass industry. Alumina industry |

|||||

| heat resistance for fireplace | ||||||

| Heat insulation, fire proof and sound insulation of aerospace, ship building industry | ||||||

| Ceramic Fiber Board | ||||||

| Item | 1050 COM | 1260 STD | 1260 HP | 1400 HA | 1450 HZ | |

| working temperature | 950℃(1742℉) | 1050℃(11942℉) | 1100℃(2012℉) | 1200℃(21922℉) | 1350℃(2462℉) | |

| density (kg/m3) | 250 | 280-450 | ||||

|

permanent linear change on

heating(%) |

950℃*24h

≤-4 |

1050℃*24h

≤-3 |

1100℃*24h

≤-3 |

1200℃*24h

≤-4 |

1350℃*24h

≤-3 |

|

|

chemical

composition |

AL2O3 | 37% | 46% | 47-49% | 52-55% | 39-40% |

| ZrO2 | —— | —— | —— | 15-17% | ||

| AL2O3+SiO2 | 96% | 97% | 99% | 99% | —— | |

| AL2O3+SiO2+ZrO2 | —— | —— | —— | —— | 99% | |

| Fe2O3 | ≤1.0% | ≤0.8% | ≤0.2% | ≤0.2% | ≤0.2% | |

| Na2O+k2o | ≤0.8% | ≤0.5% | ≤0.2% | ≤0.2% | ≤0.2% | |

| The normal size of ceramic fibre board | ||||||

| size | L*W( mm ) | 1200*1000; 1200*600; 1000*1000; 1000*600; 900*600; 600*300 | ||||

| Thickness (mm) | 3-80, 10mm | |||||

Wooden box packed filled with foam inside to avoid damage.

W e are professional supplier for several years in China for furnace and components. Our advantages are as below:

1.Hight quality, excellent technician. good team work;

2.OEM service.

3. factory wholesale price.

4.polyfoam filled inside the furnace and wooden carton package outside.

5.One year quality warranty for whole furnace/oven.