The third generation of rare earth permanent magnet NdFeB is the most powerful permanent magnet in modern magnets. It not only has the characteristics of high remanence, high coercivity, high magnetic energy product, high performance-to-price ratio, but also is easy to be processed into various sizes. Now it has been widely applied in various fields. Especially suitable for the development of high-performance, miniaturized, lightweight alternative products.

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Huajin

-

Model Number:

-

HJ-001

-

Coating:

-

Nickel/Zinc

-

Size:

-

Customized Magnet Size

-

Processing:

-

Sintered Permanent Neodymium Magnet

-

Sample:

-

Available

-

Package:

-

Magnetic Isolation Package

-

Keyword:

-

NdFeB Magnet

-

Usage:

-

Electronics,Auto Industry,Medical,Clean Tech Energy

-

OEM/ODM:

-

Acceptable

-

Working Temperature:

-

≤350℃

-

Advantage:

-

Customers' Requested Specifications

Quick Details

-

Tolerance:

-

±0.05MM

-

Grade:

-

NdFeB Magnet

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Huajin

-

Model Number:

-

HJ-001

-

Coating:

-

Nickel/Zinc

-

Size:

-

Customized Magnet Size

-

Processing:

-

Sintered Permanent Neodymium Magnet

-

Sample:

-

Available

-

Package:

-

Magnetic Isolation Package

-

Keyword:

-

NdFeB Magnet

-

Usage:

-

Electronics,Auto Industry,Medical,Clean Tech Energy

-

OEM/ODM:

-

Acceptable

-

Working Temperature:

-

≤350℃

-

Advantage:

-

Customers' Requested Specifications

Specification

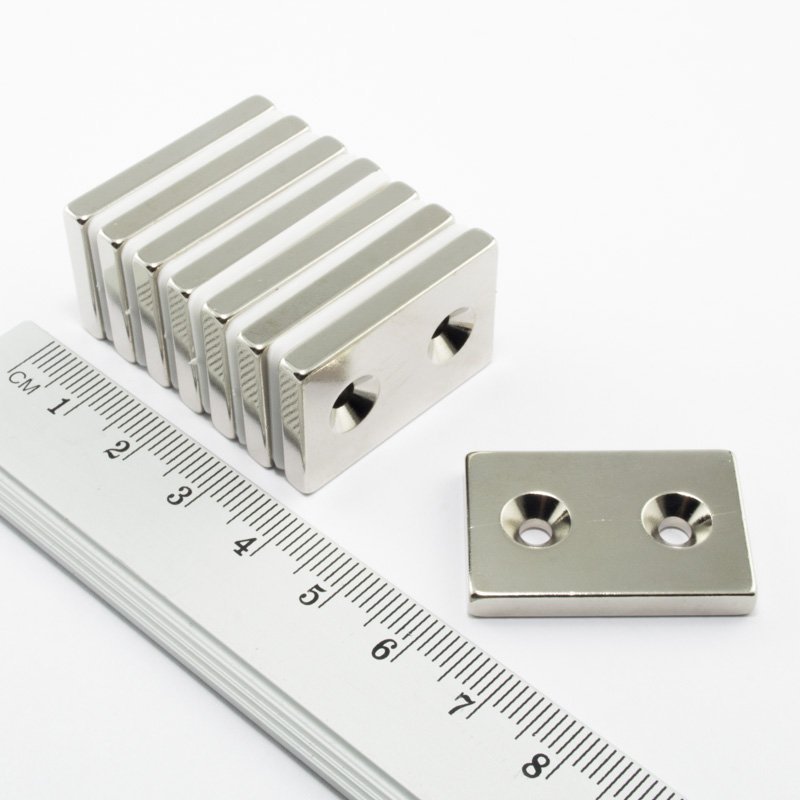

15 Years Experience Powerful N52 Neodymium Magnetic Strong Rare Earth Bar

Block Magnets High Performance Magnet

Support all Shape magnets ,

as long as you tell us the size or drawing you need, we can produce it!

|

Type

|

Permanent Sintered Neodymium Magnets / Rare Earth Magnet

|

|

Material

|

NdFeB

|

|

Shape

|

Block, Bar, Cube, Disc, Ring, Cylinder, Ball, Arc, Trapezoid, etc

|

|

Size

|

Customized according to customers’ requirements

|

|

Coating

|

Ni, Zn, Epoxy, Parylene, Gold, Passivated, etc

|

|

Density

|

7.5-7.6 g / cm³

|

|

Delivery date

|

2-4 days for common samples, 7-10 days for mass produciton

|

1) Shape and Dimension Requirements

2) Material and coating requirements

3) Processing according to design drawings

4)Requirements for Magnetization Direction

5) Magnet Grade Requirements

6) Surface treatment requirements (plating requirements)

3) Processing according to design drawings

4)Requirements for Magnetization Direction

5) Magnet Grade Requirements

6) Surface treatment requirements (plating requirements)

|

Magnetic Grade

&

Working Temperature

|

Magnetic Grade

|

Working Temperature

|

|

|

N35-N45

|

80 ℃ (176 ℉)

|

|

|

N48-N52

|

60 ℃ (160 ℉)

|

|

|

35M-52M

|

100 ℃ (212 ℉)

|

|

|

33H-50H

|

120℃ (248 ℉)

|

|

|

33SH-45SH

|

150 ℃ (302 ℉)

|

|

|

30UH-40UH

|

180 ℃ (356 ℉)

|

|

|

28EH-38EH

|

200℃ (392 ℉)

|

|

|

28AH-33AH

|

220 ℃ (428 ℉)

|

Magnet Categories

We can accept customized products of

any shape, size, performance and electroplating.

just send us your Request and we'll supply you the most economical solution for your project.

If you are interested in our neodymium magnets, please feel free to contact us.

We would be delighted to provide you with

free samples

to help you experience the exceptional quality of our products firsthand.

Magnetization Direction

Common direction of magnetization showed in picture bellow:

1> Disc, cylinder and Ring shape magnet can be magnetized Axially or Diametrically.

2> Rectangle magnets can be magnetized through Thickness, Length or Width.

3> Arc shape magnets can be magnetized Diametrically, through Width or Thickness.

Special direction of magnetization can be customized as required.

Grade/Coating

Support all magnet plating , like Ni-Cu-Ni, Zn, Epoxy , Gold, Silver etc.

2>

There are a variety of options for coatings, but nickel is the most common and usually preferred.

Our nickel plated magnets are actually triple plated with layers of nickel, copper, and nickel again. This triple coating makes magnets much more durable than the more common single nickel plated magnets.

3>

Other options of coating are zinc, tin, copper, epoxy,silver and gold.

Customer Feedback

More products

Application

1). Electronics – Sensors, hard disk drives, sophisticated switches, electro-mechanical devices etc.;

2). Auto Industry – DC motors (hybrid and electric), small high-performance motors, power steering;

3). Medical – MRI equipment and scanners;

4). Clean Tech Energy – Water flow enhancement, wind turbines;

5). Magnetic Separators – Used for recycling, food and liquids QC, waste removal;

6). Magnetic Bearing – Used for highly sensitive and delicate procedures in various heavy industries.

Hot Searches