- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V 380V 415V 440V 460V

-

Dimension(L*W*H):

-

3500*3200*2800mm

-

Year:

-

2020

-

Warranty:

-

3 Years

-

Weight (KG):

-

9800 kg

-

Power (kW):

-

45

-

Certification:

-

CE ISO9001 SGS

-

Type:

-

Open Mixing Mill

-

Application::

-

waste tyre recycling

-

Automatic Grade::

-

Automatic

-

Name::

-

Fully Automatic Waste Tyre Recycling Machine

-

two kind of reducer:

-

hardended reducer,big and small gear reducer

-

two kind gear box::

-

planet gear box , hardened gear box

-

two kind of bush::

-

nylon bush and bearing bush

-

gap adjustment::

-

electric

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Chaoguangyue

-

Model Number:

-

LPS900/1200

-

Voltage:

-

220V 380V 415V 440V 460V

-

Dimension(L*W*H):

-

3500*3200*2800mm

-

Year:

-

2020

-

Warranty:

-

3 Years

-

Weight (KG):

-

9800 kg

-

Power (kW):

-

45

-

Certification:

-

CE ISO9001 SGS

-

Type:

-

Open Mixing Mill

-

Application::

-

waste tyre recycling

-

Automatic Grade::

-

Automatic

-

Name::

-

Fully Automatic Waste Tyre Recycling Machine

-

two kind of reducer:

-

hardended reducer,big and small gear reducer

-

two kind gear box::

-

planet gear box , hardened gear box

-

two kind of bush::

-

nylon bush and bearing bush

-

gap adjustment::

-

electric

Your best choice:

CGY Waste Tyre Shredder For Recycling Equipment Tire Shredding Machine

Brief description:

Fully automatic waste tyre recycling machine,used to manufacture all various of size of rubber powder(crumb)

the inout capacity : 8000 tons per year

the output capacity: 5000-7000 tons per year for 10-30 mesh rubber powder.

worker : 2-3

floor area: 1200 SQ.M

power:272.8KW

suitable for both radial tyres and nylon/fiber tyres.

Production capacity and energy consumption:

|

NO |

MODEL |

Total Power(KW/h) |

Production Capacity (kg/h) |

|

1 |

XKP-400 line |

About 103.2kw |

400-500kg for around 10-30 mesh rubber powder. |

|

XKP-450 line |

About 113.2kw |

600-700kg for around 10-30 mesh rubber powder |

|

|

XKP-560 line |

About 132.2KW |

800-1000kg for around 10-30 mesh rubber powder. |

|

|

Floor space:About 300-400 m2, Workers needed:3 operator and 1 maintainer |

|||

Working Process:

Draw steel wire from the tire ring by Tire wire drawing machine-if the diameter of tire is bigger than 825mm, can choose to use tire cutting machine to cut the tire to several pieces--- put the small tires or pieces into tire shredder to make tire blocks-put the tire blocks to the tire crusher to make rubber powder-finished rubber powder.

Flow Chart:

Waste tire---whole tire de-beader---whole tire cutting---whole tire shredding---Rubber crushing--- magnetic separating(Nylon fiber separator if recycle nylon tires) ---Rubber powder

1, Whole tire debeader-

whole tire wire drawing machine( Draw out the steel wires from the tire bead. )

|

Model No. |

TD-1200 |

|

Feed size of tire(mm) |

≤φ1200 |

|

Capacity(tires/h) |

80-100 |

|

Power(KW) |

7.5 |

|

Overall dimensions(m) |

4.7*0.9*1.7 |

|

Equipment weight (T) |

2.8 |

2, Whole tire cutter

Functions: Whole tire cutter , it is used to cut big tires into small pieces.

|

Model No. |

TC-1200 |

TC-1400 |

|

Feed size of tire(mm) |

≤φ1200 |

≤φ1400 |

|

Capacity(tires/h) |

30-40 |

30-40 |

|

Power(KW) |

4 |

7.5 |

|

Overall dimensions(m) |

2.2*0.8*1.5 |

2.4*1.0*2.0 |

|

Equipment weight (T) |

1.2 |

2.5 |

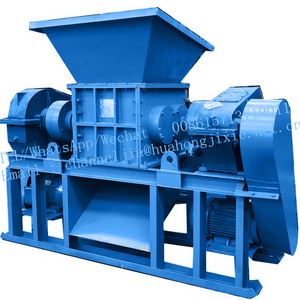

3,Whole tire shredder

This whole tire shredder can cut whole tire into 50x50mm , and 60x60mm rubber block as you need.

|

Model |

TS-900 |

TS-1200 |

|

Production capacity |

0.8-2ton/h |

1.5-3ton/h |

|

Size of feeding |

≤900mm whole tyre |

≤1200mm whole tyre |

|

Specification of the slice |

≤50*50mm |

≤60*60mm |

|

Motor power |

45kw |

55kw |

|

Cutter rotate speed |

16r/min |

31r/min |

|

Screener rotate speed |

6r/min |

8r/min |

|

Dimension |

2.8*2.1*2.4m |

5.2*2.8*3.5m |

|

Weight |

6.2T |

14.8T |

4.Rubber crusher

|

Type&Specification |

XKP-400 |

XKP-450 |

XKP-560 |

|

Feeding size |

3.5CM |

3.5CM |

3.5CM |

|

Discharging size |

10—30 mesh powder |

10--30 mesh powder |

10--30 mesh powder |

|

Rubber crusher throughput(kg/h) |

100--150kg |

250—300kg |

350—420kg |

|

Motor power(kw) |

45 |

60 |

75 |

|

Outside measurement(m) |

4.1×1.8×1.9 |

4.4×1.9×1.9 |

5.5×2.2×2.1 |

|

Weight(t) |

7.5 |

11 |

19 |

5, Auxiliary Equipment

6, Application:

Workshop and customers visiting:

Others lines:

1, The whole production line for reclaimed rubber sheet:

KNEADER- CONVEYOR-- OPEN MIXING MILL-- CALENDER--BATCH OFF COOLER

2, Rubber powder to Reclaimed Rubber Making Line:

Our cert: CE,SGS,ISO9001

FAQ:

1,Are you manufacturer?

Yes,we are BV approved rubber products manufacturer in China.

2,Can you design new product for us?

Yes,we have a professional development team that make new products according to your requirements.

3,Can you supply sample?

Yes,we can supply you free small samples,but air cost will be paid by customers.

4,What’s your payment term?

Common is 30% deposit by T/T,the balance paid against shipping documents.

Or L/C at sight.

5,Are you near to Qingdao airport?

Yes,only within 1.5hours.

And within 1 hour to Qingdao sea port.

50 minutes to Qingdao Railway Station.

6,Do you have any certificate of your products?

Yes, CE, BV, SGS, REACH.

7,Do you have any certificate of your company?

Yes, ISO 9001:2000.

8,Did your products apply the patent?

Yes,we have waste tyre recycling machine & rubber tile making machine protector patent.