Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

beilijia

-

Voltage:

-

Customized

-

Dimension(L*W*H):

-

Customized

-

Power (kW):

-

133

-

Weight:

-

25000 KG

Quick Details

-

Screw Design:

-

Single-screw

-

Screw L/D Ratio:

-

34:1

-

Screw Speed (rpm):

-

120 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

beilijia

-

Voltage:

-

Customized

-

Dimension(L*W*H):

-

Customized

-

Power (kW):

-

133

-

Weight:

-

25000 KG

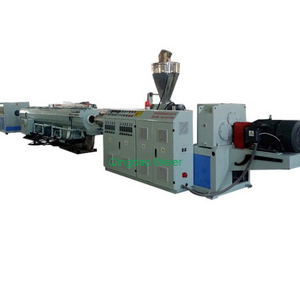

Products Description

Plastic twin screw extruder

●

The difference of twin-screw host is that its ingredient cost is low, and it is suitable for manufacturing medium and high-end products.

●

The screw is made of alloy material, which can achieve better wear resistance and high plasticity compared to ordinary screws

●

Feeding, the spiral feeding rod inside is made of round steel, which is more accurate in feeding speed and plasticizes the area under high temperature conditions.

●

And this machine uses a permanent magnet motor, which has the advantage of absolute control over energy loss in long-term production.

The host is equipped with high-speed and efficient screws

The motor adopts a servo motor

This is our high-speed screw model 120/38 150/38

Frequency converter in the distribution cabinet

Adopting the ETD brand from the United States, our investment in electrical systems is superior to most domestic equipment manufacturers.

Competitive Advantage:

1)It adopts advanced technology and results in high output, good plasticization and wide applications.

2)It is suitable for various TEO plastic materials such as HDPE, PPR, PP, ABS and PMMA.

3)Advanced computer module control system enables implementation of automatic control on overall production line.

4)Temperature control system of excellent performance ensures stable output.

5)Powerful driven system assures durablity and easy maintenance.

6)Design of compulsively water-cooling and feeding grooved sleeve ensures steady and even production.

7)Electricity-resistant heating ring and super noise-free ventilator is designed imitating imported product.

8)Low-abrasion design of screw

9)High fusion of material

10)Even fusing material

11)Low consumption of energy

12)Excellent effect of prefabricated mixture production

|

Model

|

Diameter of screw(mm)

|

L/D ration

|

Main motor(KW)

|

Output(kg/h)

|

|

SJ45*25

|

45

|

25:1

|

7.5

|

5-38

|

|

SJ45*33

|

45

|

33:1

|

30

|

100-130

|

|

SJ65*25

|

65

|

25:1

|

22

|

20-85

|

|

SJ65*30

|

65

|

30:1

|

30

|

30-110

|

|

SJ65*33

|

65

|

33:1

|

75

|

150-200

|

|

SJ75*30

|

75

|

30:1

|

90

|

200-300

|

|

SJ90*25

|

90

|

25:1

|

55

|

50-100

|

|

SJ90*33

|

90

|

33:1

|

185

|

350-500

|

|

SJ120*25

|

120

|

25:1

|

75

|

50-250

|

|

SJ120*33

|

120

|

33:1

|

280

|

600-850

|

|

SJ150*25

|

150

|

25:1

|

100

|

370

|

|

SJ150*33

|

150

|

33:1

|

315

|

800-1000

|

|

SJ150*34

|

150

|

34:1

|

355

|

900-1200

|

|

SJ200*25

|

200

|

25:1

|

132

|

180-430

|

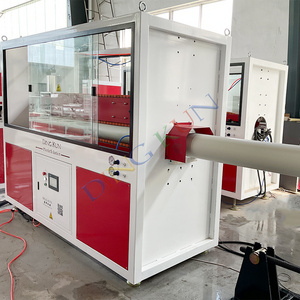

Sample display

Hot Searches