Powerjet Single Station Extrusion Blow Molding Machine EB250P is specialized for manufacturing bottles and containers which Max 30L.

Max Bottle Capacity – 30(L)

Clamping Force – 200(KN)

Extrusion Weight(HDPE) – 80(kg/hr)

Applications – Wide Range Of Bottles For Daily necessities, toiletries, beverages, water tanks, laundry detergent/shower gel/motor

oil bottles, etc

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Powerjet

-

Voltage:

-

380

-

Dimension(L*W*H):

-

4.7*3.5*3.4

-

Hollow part volume:

-

30L

-

Screw L/D Ratio:

-

24

-

Screw diameter (mm):

-

85 mm

-

Screw Heating Power(kW):

-

30 kW

-

Extruder Motor Power(kW):

-

22 kW

-

Mold Platen Size(Width)(mm):

-

760 mm

-

Mold Platen Size(Height)(mm):

-

760 mm

-

Air Pressure(MPa):

-

0.8 MPa

-

Air Comsumption(m³/min):

-

2.0 m³/min

-

Die Head Heating Power(kW):

-

35 kW

-

Accumulator Capacity(L):

-

30 L

-

Power (kW):

-

30

-

Weight (T):

-

11

-

Keywords:

-

Chemical Double Layer Drum Extrusion Blow Molding Machine

-

Station:

-

Single Sation

-

Brand:

-

Powerjet

-

Model Number:

-

EB250P

-

Suitable bottle:

-

30L

-

Color:

-

Blue

-

After-sales Service Provided:

-

Field maintenance and repair service

-

brand:

-

Powerjet

Quick Details

-

Clamping Force (kN):

-

200

-

Output (kg/h):

-

125 kg/h

-

Place of Origin:

-

China

-

Brand Name:

-

Powerjet

-

Voltage:

-

380

-

Dimension(L*W*H):

-

4.7*3.5*3.4

-

Hollow part volume:

-

30L

-

Screw L/D Ratio:

-

24

-

Screw diameter (mm):

-

85 mm

-

Screw Heating Power(kW):

-

30 kW

-

Extruder Motor Power(kW):

-

22 kW

-

Mold Platen Size(Width)(mm):

-

760 mm

-

Mold Platen Size(Height)(mm):

-

760 mm

-

Air Pressure(MPa):

-

0.8 MPa

-

Air Comsumption(m³/min):

-

2.0 m³/min

-

Die Head Heating Power(kW):

-

35 kW

-

Accumulator Capacity(L):

-

30 L

-

Power (kW):

-

30

-

Weight (T):

-

11

-

Keywords:

-

Chemical Double Layer Drum Extrusion Blow Molding Machine

-

Station:

-

Single Sation

-

Brand:

-

Powerjet

-

Model Number:

-

EB250P

-

Suitable bottle:

-

30L

-

Color:

-

Blue

-

After-sales Service Provided:

-

Field maintenance and repair service

-

brand:

-

Powerjet

Products Description

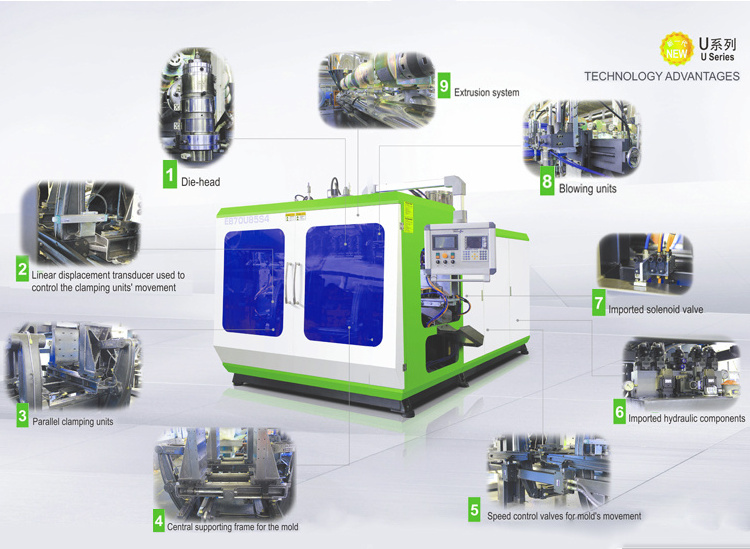

TECHNOLOGY

1.Die-head

2.Linear displacement transducer used to control the clamping units' movement

3.Parallel clamping units

4.Central supporting frame for the mold

5.Speed control valves for mold's movement

6.Imported hydraulic components

7.Imported solenoid valve

8.Blowing units

8.Blowing units

9.Extrusion system

FEATURES:

1:Toggle balance clamping structure, with platen opening & clamping and mold platen movement by linear guide, to achieve low friction and high speed.

2:Based on the Finite Element Analysis design, and platen, toggle and platen frame made in high intensity nodular cast iron.

3:High speed mold clamping oil cylinder with differential speed function, and high speed mold moving cylinder with special anti-shock cushion valve structure.

4:Specially designed to screw with high L/D ratio insures good plasticizing and stable extrusion; high precision and no part line die head guarantees customers’ top quality requirement.

5:Multi-screw & multi-die head can be adopted to improve the quality of the product and lower down the cost of material.

6:Multiple-way PID controlled temperature heating is precise and stable.

1:Toggle balance clamping structure, with platen opening & clamping and mold platen movement by linear guide, to achieve low friction and high speed.

2:Based on the Finite Element Analysis design, and platen, toggle and platen frame made in high intensity nodular cast iron.

3:High speed mold clamping oil cylinder with differential speed function, and high speed mold moving cylinder with special anti-shock cushion valve structure.

4:Specially designed to screw with high L/D ratio insures good plasticizing and stable extrusion; high precision and no part line die head guarantees customers’ top quality requirement.

5:Multi-screw & multi-die head can be adopted to improve the quality of the product and lower down the cost of material.

6:Multiple-way PID controlled temperature heating is precise and stable.

EB250P Automatic Extrusion Blow Molding M

achine

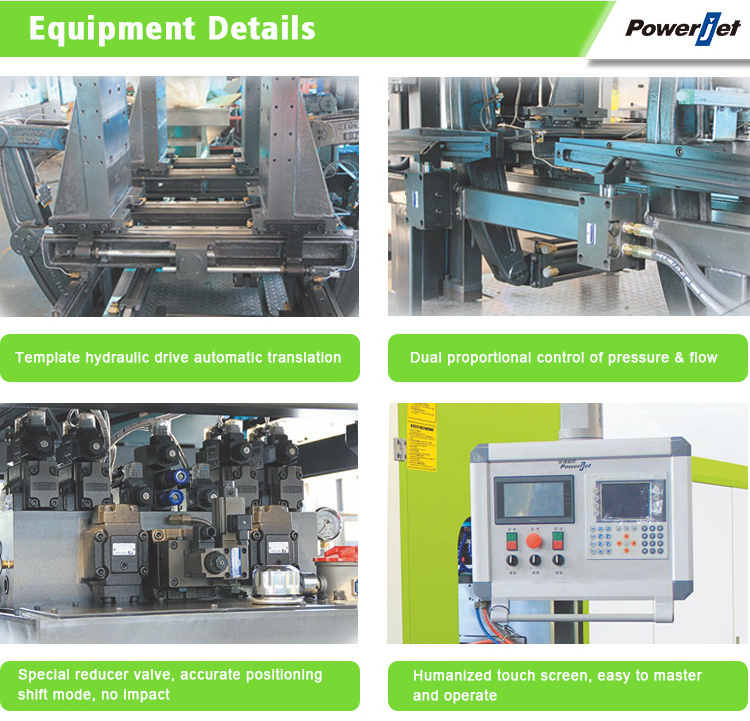

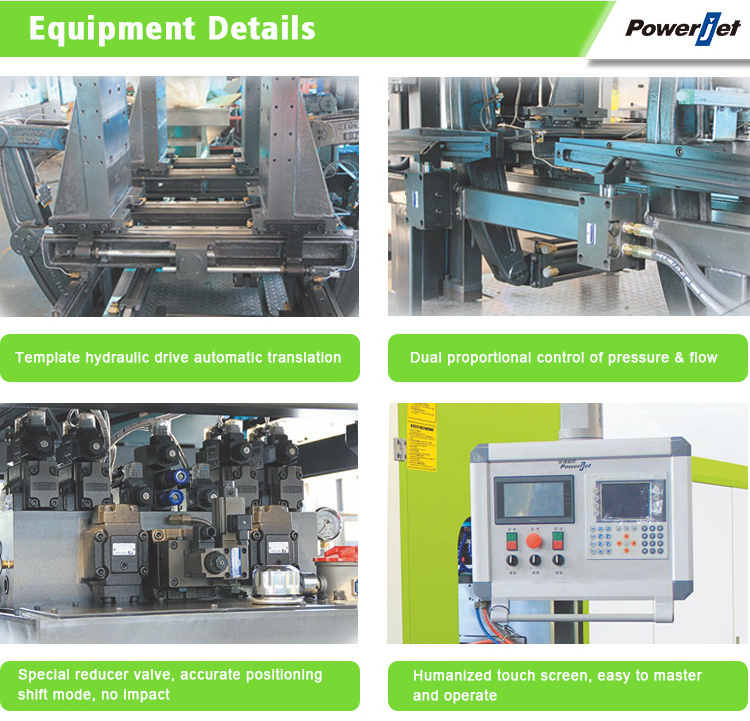

Template hydraulic drive automatic translation

Dual proportional control of pressure & flow

Special reducer valve, accurate positioning shift mode, no impact

Humanized touch screen, easy to master and operate

1.Rotary Trimming Equipment 2.Auto Deflashing Equipment 3.Rotary Trimming Configuration 4.Die Head

5.Optional for all Accessory Equipment 6.Mould 7.Parison Controller

Product Paramenters

|

Model

|

|

EB250P

|

|

|

Max. Product

|

L

|

30

|

|

|

Clamping Force

|

KN

|

200

|

|

|

Screw Diameter

|

mm

|

Φ85

|

|

|

Screw L/D Ratio

|

L/D

|

24

|

|

|

Screw Rotary Speed

|

RPM

|

65

|

|

|

Extrusion Weight (HDPE)

|

kg

|

125

|

|

|

Extrusion Motor Power

|

KW

|

30

|

|

|

Pump Motor Power

|

KW

|

22

|

|

|

Heating Capacity

|

KW

|

35

|

|

|

Operation Pressure

|

Mpa

|

0.6~0.8

|

|

|

Air Consumption

|

m3/min

|

2.0

|

|

|

Cooling Water Consumption(25°c)

|

L/min

|

120

|

|

|

Machine Dimensions (LXWXH)

|

m

|

4.7*3.5*3.4

|

|

|

Machine Weight

|

T

|

11

|

|

Hot Searches