- Pneumatic Unwind Shaft: 76.200 mm (3") core ID, after expansion

- Magnetic Powder Brake

- Maximum Unwind Diameter: 500 mm (19.685")

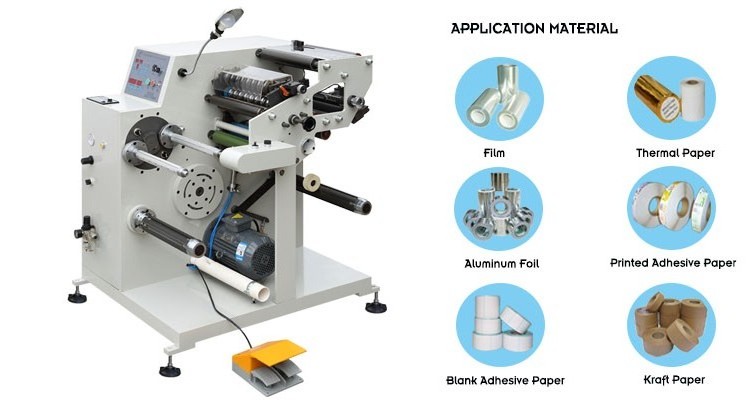

DBFQ-320S automatic slitting rewinding machine is an updated model of DBFQ-320A, it remains the function of DBFQ-320A slitting rewinding machine, and adopt turret rewinding style at up rewinder, and keep easily exchange mode between different diameter size of aishafts. The increase of the preparatory airshaft improves the working efficiency of the slitting machine and is suitable for cutting paper of different core sizes.The structure of the complete machine is compact, with high speed, high efficiency, easy and steady operation.

|

Specification of DBFQ-320S Automatic Slitting Rewinding Machine

|

|

|

||

|

Model

|

DBFQ-320S

|

DBFQ-450S

|

||

|

Max. Slitting Speed

|

80m/min

|

80m/min

|

||

|

Max. Web Width

|

330mm

|

480mm

|

||

|

Max. Slitting Width

|

320mm

|

450mm

|

||

|

Min. Slitting Width

|

17mm

|

17mm

|

||

|

Max. Unwinding Diameter

|

500mm

|

500mm

|

||

|

Max. Up Rewinding Diameter

|

220mm

|

220mm

|

||

|

Max. Down Rewinding Diameter

|

400mm

|

400mm

|

||

|

Precision of Slitting

|

± 0.1mm

|

± 0.1mm

|

||

|

Standard Blades

|

6sets circular knives

|

6sets circular knives

|

||

|

Power of the Machine

|

3.0KW

|

3.0KW

|

||

|

Voltage

|

220V

|

220V

|

||

A it keeps a hole on the top of the airshaft, can be fixed by the cylinder when do rewinding job, makes the airshaft running without shake, the material rewind more stable and smoothly.

B Switch for cylinder

C switch for additional rubber roller.

D cylinder part inside

E additional press rubber roller to press material, fixxing the material when changing rollers. the exchange of roller easlier

F we use belf instead of chain on the back side of the machine

G the backside part of up turret rewinder

H the backside part of unwinder

- Pneumatic Unwind Shaft: 76.200 mm (3") core ID, after expansion

- Magnetic Powder Brake

- Maximum Unwind Diameter: 500 mm (19.685")

.

- with two cylinder controlled paper grippers

- with two

grooves

- Interchangeable Slitting Module for Rotary Shear Knives or Razor Blade attachment

- 6 sets Rotary Shear Slitting Blades

- 6 nos. Razor Blade Holders with Grooved Support Shaft and recommended for slitting thin unsupported filmic substrates while it can slit other standard substrates too

- Minimum Slitting Width (for Rotary Knives): 18 mm (0.709")

- Minimum Slitting Width (for Razor Blades): 12 mm (0.472")

- Maximum Slitting Width: 300 mm (11.811")

- Slitting Accuracy: +/- 0.10 mm (0.004")

- Maximum Slitting Speed (Dependent on Substrate/Application) : 100 m/min

- Semi-Turret Rewinder with dual shafts of 25.400 mm (1.000") core ID, after expansion

- Interchangeable TOP SHAFT for Semi-Turret Rewinding System: optional Semi-Turret Rewinder with dual shafts of 38.100 mm (1.500") core ID, or 76.200mm (3") after expansion

- Magnetic Powder Clutch

- Maximum Rewind Diameter: 300 mm (11.811")

- Pneumatic Rewinder Shaft: standard 76.200 mm (3") core ID, after expansion

- Magnetic Powder Clutch

- Maximum Rewind Diameter: 480 mm (18.898")

- Upgraded air shaft with centralized air supply mechanism requiring no air gun, but on/off switch

- French Schneider brand inverter for speed control

- Driven by Belt System instead of conventional Chain system

- Label Number Counting by China contrast sensor or length counting

- Easy programmable pre-set counter for auto slow down and stop

- Waste Extraction with suction motor

1. Wrapping by stretch film material with the machine inside;

2. Packed by fumigated wooden case outside;

3. Deliveried by container;

4. Generally shipping by sea, optional shipping by air or train way

1. Professional Guaidance;

2. One year quality warantty;

3. Whole life service support;

4. Accept print your logo or brand on the machine

A: Usually finish the production within 30days after your 30% advanced payment, actually need to check according our stock & production plan.

A: We accept T/T, 30% in advance and 70% balanced against B/L copy.

We accept L/C at sight.

We accept Cash.

A: We will finish installation and training within 15days.

A: All our machine have one year guarantee, starting from finished installation.

A: We also can do service for you, however, if require overseas service, you need pay salary to our technician 100USD/day.

A: We would express the free replacement parts during the warranty date.

A: For flexo printing, slitting, die-cutting machine, only need one person for each.

A: You should charge for the cost of our engineer's visa , air tickets, hotel, food ,and also their salary 100USD one day per person.

For other question, please don't hesitate to contact us: