2.

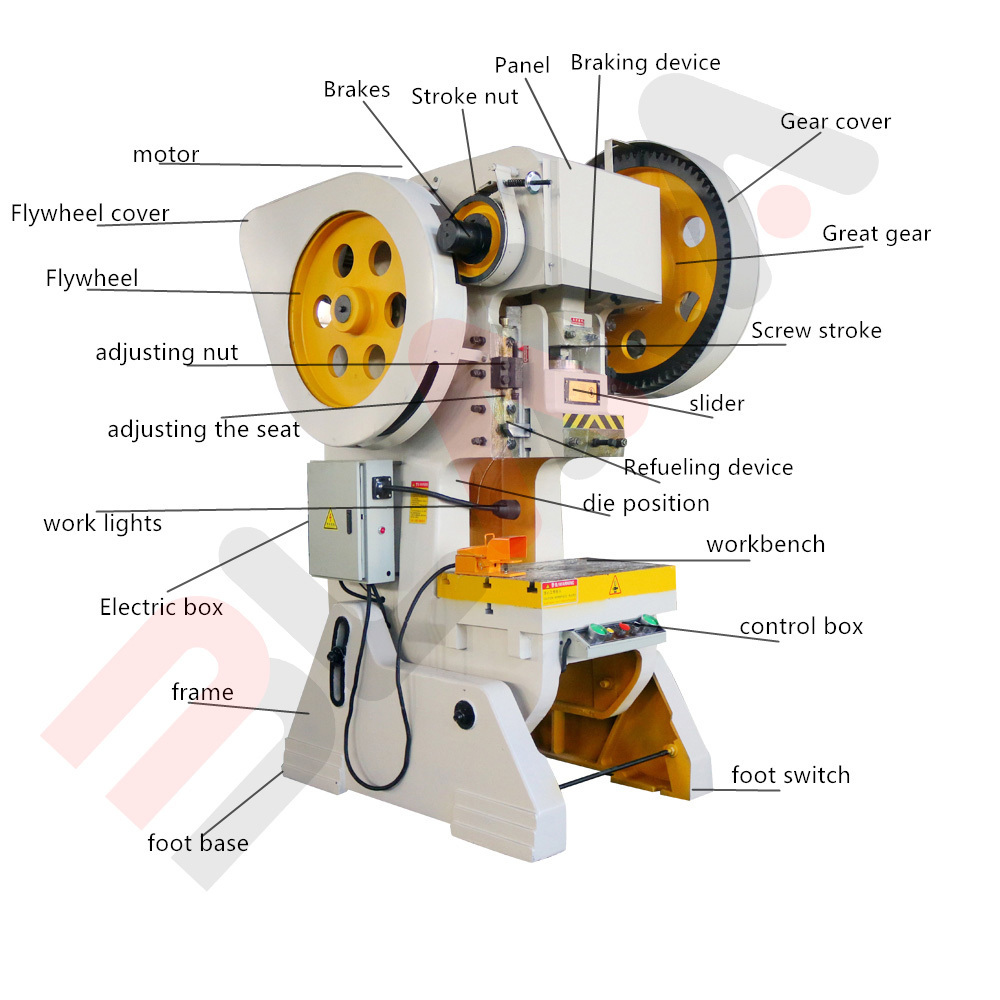

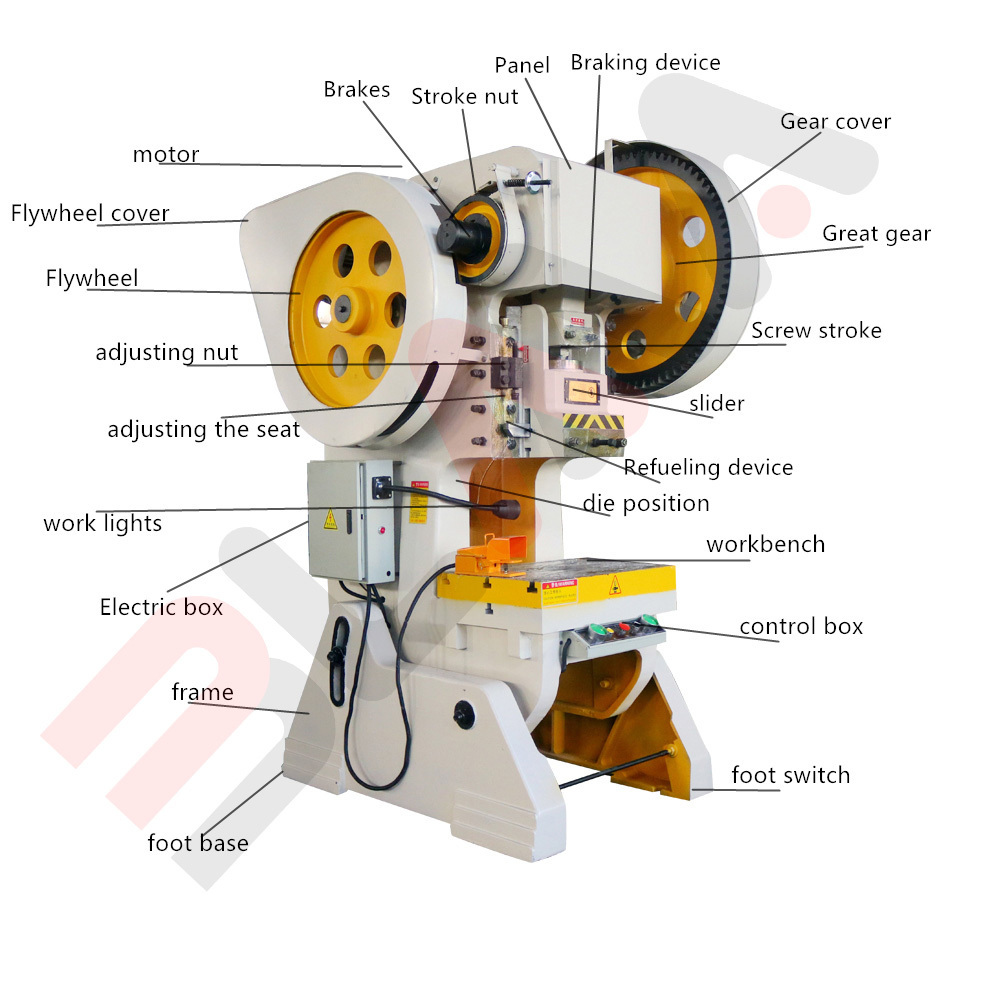

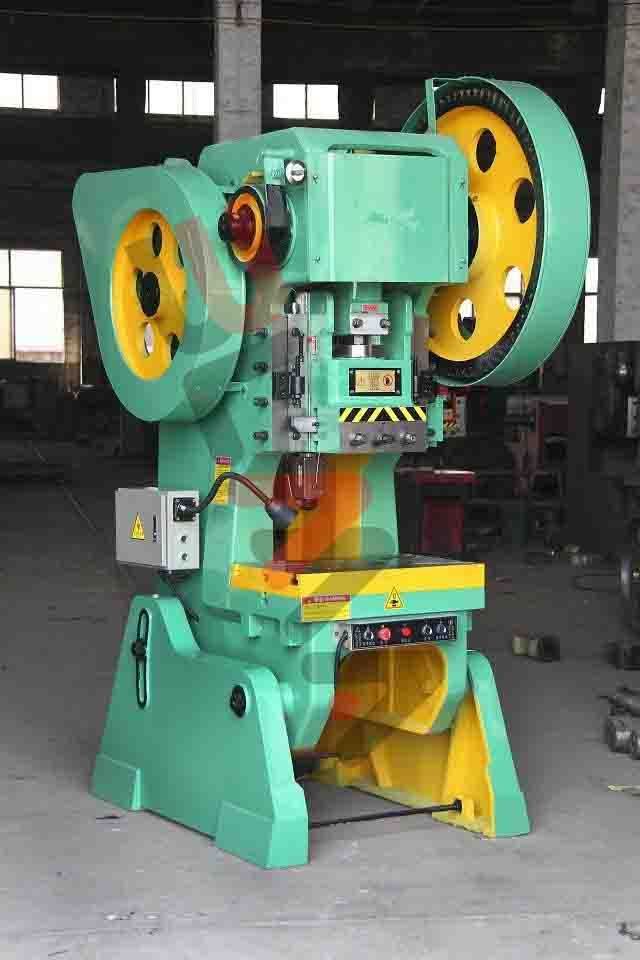

Steel-welded frame, high rigidity and less deformation Compact.

3.

Thick plates and large columns provide you with the stable platform you need for your demanding application.

4.

High accuracy, high efficiency, simple and convenient operation, good performance.

5.

Wide body frame eliminating vibration for improved ide life and machine,which means economical and practical.

6.

Operation space is wide, and the movable bolster could be moved out of frame to set the die. The structure is simple and the

appliance is also beautiful.

appliance is also beautiful.