- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

VANEST

-

Power (kW):

-

7.5

-

Weight (KG):

-

2500 KG

-

Product name:

-

Nail Making Machine

-

Wire diameter range:

-

3-6.0 mm

-

length range:

-

60-200 mm

-

Motor POWER:

-

7.5KW

-

Capacity:

-

150 pieces/minute

Quick Details

-

Production Capacity:

-

150 pieces/minute

-

Marketing Type:

-

New Product 2024

-

Place of Origin:

-

China

-

Brand Name:

-

VANEST

-

Power (kW):

-

7.5

-

Weight (KG):

-

2500 KG

-

Product name:

-

Nail Making Machine

-

Wire diameter range:

-

3-6.0 mm

-

length range:

-

60-200 mm

-

Motor POWER:

-

7.5KW

-

Capacity:

-

150 pieces/minute

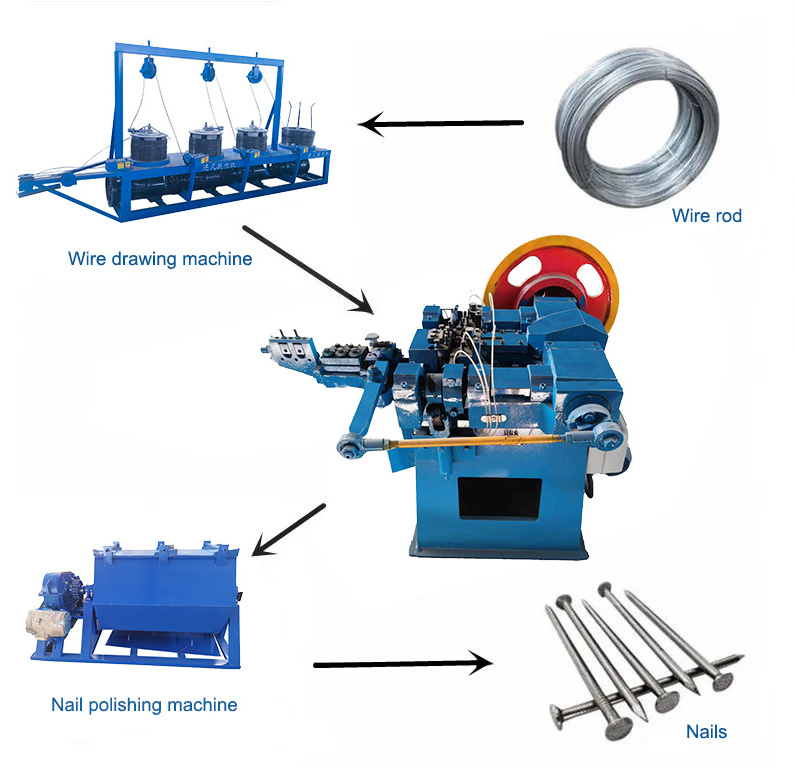

Products Description

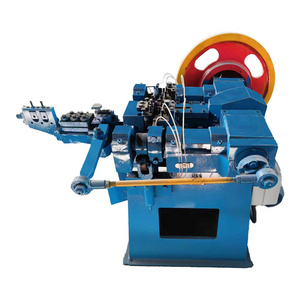

Automatic Wire Nail Making Machine

V-1C V-

2C

V-

3C

V-

4C

V-

5C

V-

6C

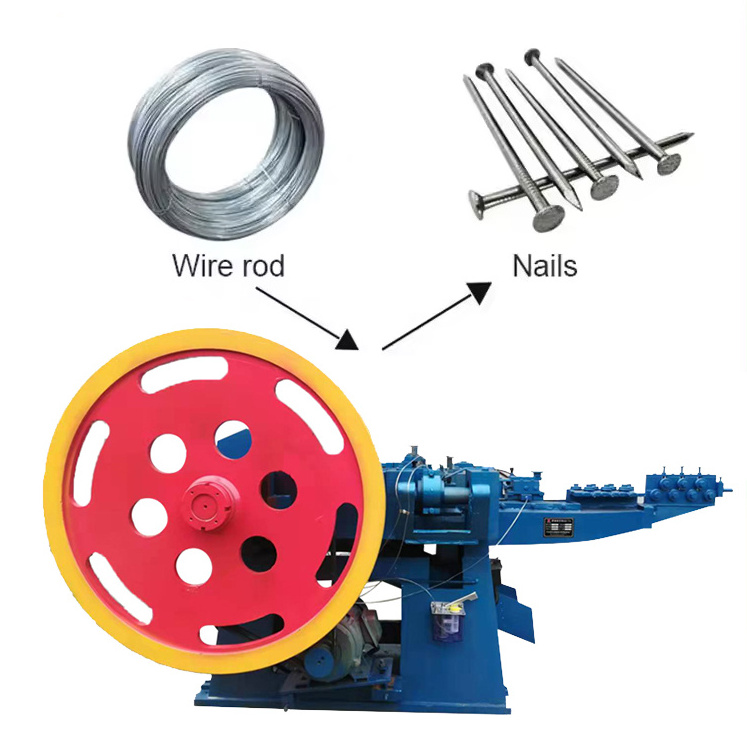

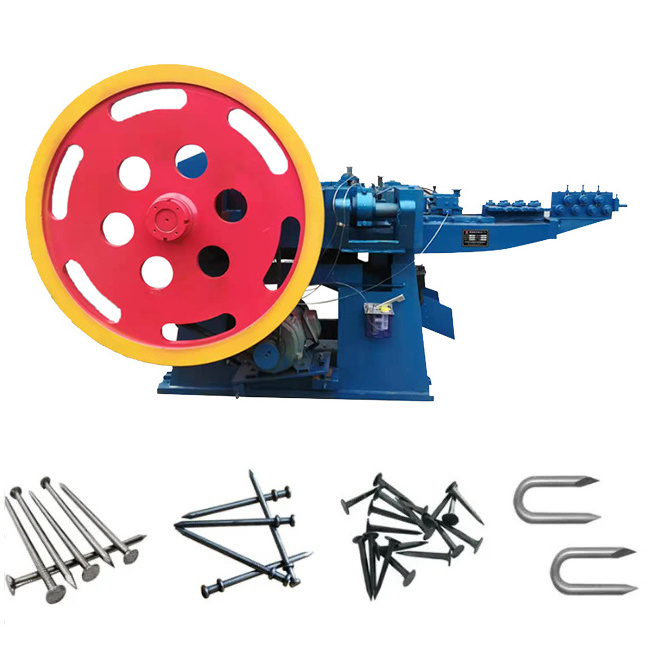

The new generation of V series high efficient, low noise with super performance automatic nail making machine is mainly used for manufacturing steel nails.

The machine is also able to manufacture other steel nails with special specifications, such as double-cap nail, felt nail,

V-nail,corrugated plate nail, U-nail, injecting-nail, gun nail and etc. after little reformation. The manufactured nails can be

extensively used in industry, building, repairing and etc.

|

Model

|

V-1C

|

V-2C

|

V-3C

|

V-4C

|

V-5C

|

V-6C

|

|

Nail Length (mm)

|

9-25

|

15-50

|

20-80

|

30-110

|

40-150

|

60-200

|

|

Nail Dia. (mm)

|

0.9-1.6

|

1.2-2.8

|

1.5-3.5

|

2-5

|

2.5-5.5

|

3-6

|

|

Motor power(kw)

|

1.5

|

2.2

|

3.0

|

4.0

|

5.5

|

7.5

|

|

Output(pcs/min)

|

500

|

340

|

300

|

200

|

200

|

200

|

|

L*W*H(m)

|

1.5*0.84*0.9

|

1.65*1.2*1.2

|

1.9*1.4*1.2

|

2.3*1.5*1.4

|

2.4*1.6*1.5

|

3.2*1.8*1.7

|

|

Weight(kg)

|

400

|

800

|

1000

|

1800

|

2000

|

2300

|

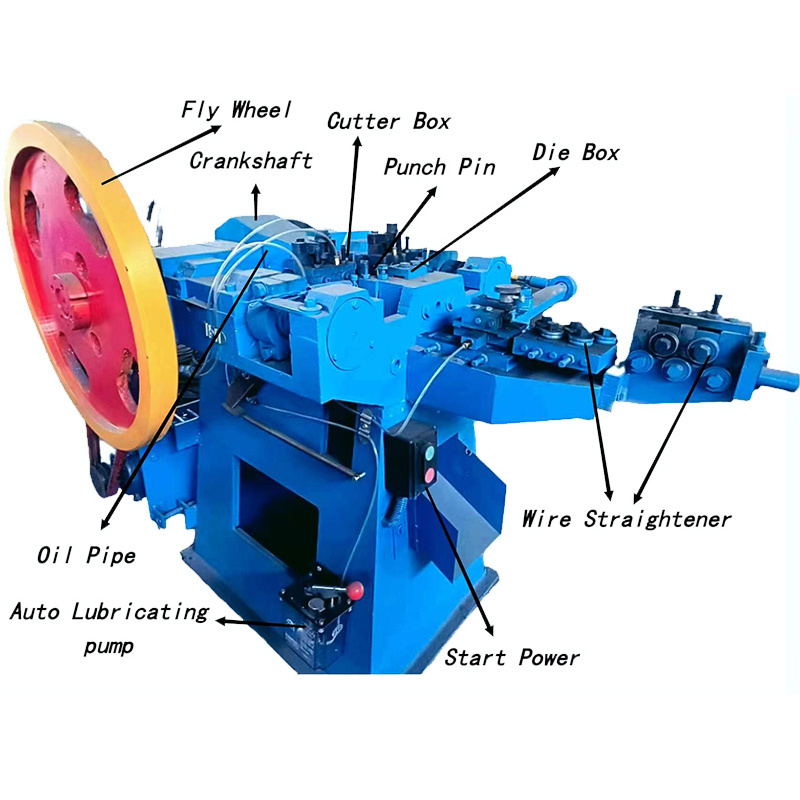

This machine adopts plunger type stricture so as to ensure the features such as high speed, low noise and less impact.

Especially, it can make the high quality of oil rivet nail, roofing nails, U nails and double-head nails.

Each model machine could make different kinds size nail, the nail length could adjust on machine and a set of free mold (nail knife and punch pin ect. spare parts) for Each nail making machine .

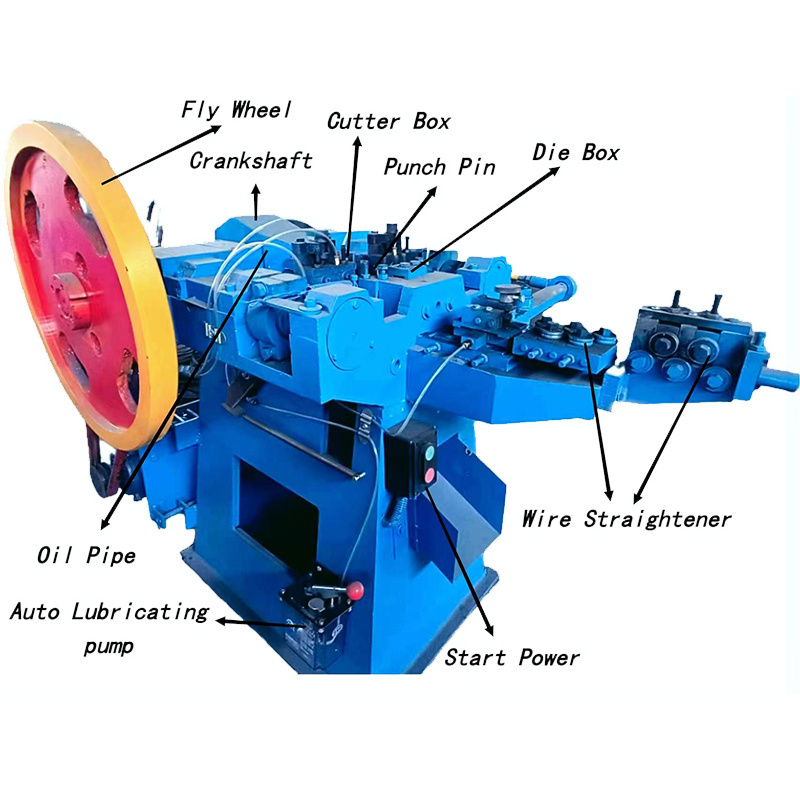

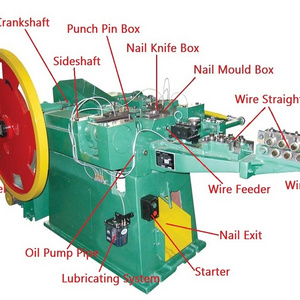

Working principle:

The machine has only one piece punch bar, one pair nail die, and one pair nail cutter, the machine nail die will grip the steel wire and the punch bar will punch to get the nail head, and the nail cutter to cut the nail point.

Working principle:

The machine has only one piece punch bar, one pair nail die, and one pair nail cutter, the machine nail die will grip the steel wire and the punch bar will punch to get the nail head, and the nail cutter to cut the nail point.

This structure decides that it can make only one nail per time.

This type nail-making machine adopts a plunger structure, driven by 3 phase electric motor and is equipped with auto oil pipe lubrication.

This type nail-making machine adopts a plunger structure, driven by 3 phase electric motor and is equipped with auto oil pipe lubrication.

Details Images

Wire Nail Making Process:

1. Wire Straightening: put the wire coil on pay-off rack and input wire to straightening device for straightening.

2. Wire Feeding: The feeding box will grip and feed the steel wire continuously.

3. Nail head Forming: When the steel wire is clamped by the gripping mechanism, the punch system will punch the wire to form the nail head.

4. Nail Tip Cutting: After the extrusion is completed, the cutting mechanism cuts the wire, and an emergency return mechanism can be used.

5. Final Step: The gripping die open, the nail is dropped down and the next nail will be made continuously.

1. Wire Straightening: put the wire coil on pay-off rack and input wire to straightening device for straightening.

2. Wire Feeding: The feeding box will grip and feed the steel wire continuously.

3. Nail head Forming: When the steel wire is clamped by the gripping mechanism, the punch system will punch the wire to form the nail head.

4. Nail Tip Cutting: After the extrusion is completed, the cutting mechanism cuts the wire, and an emergency return mechanism can be used.

5. Final Step: The gripping die open, the nail is dropped down and the next nail will be made continuously.

Advantages of the machine

:

* Can make a wide range of wire nails according to different models.

* Can make a wide range of wire nails according to different models.

* Fully automatic.

* Low running cost.

* Cheap spare parts price.

* Low power consumption as with just 4 kilowatts of power.

* Simple construction and Easy on nail adjustment:

* Low running cost.

* Cheap spare parts price.

* Low power consumption as with just 4 kilowatts of power.

* Simple construction and Easy on nail adjustment:

ONLY 10 minutes To change the nail diameter and change the nail mold. ONLY 5 minutes To adjust the nail length, nothing needs to be changed.

Hot Searches