- Product Details

- {{item.text}}

Quick Details

-

Control System:

-

Automatic Manual All-in-One

-

Service:

-

OEM, Accepte Customized Order

-

Name:

-

Deposition Magnetron sputtering vacuum coating machine/ vacuum chamber

-

Sample:

-

Available

-

MOQ:

-

1 Set

-

Business Type:

-

China Manufacturer/Factory

-

Technic:

-

Multi-Arc Ion

-

Weight:

-

As Per Design

-

Certification:

-

CE, ISO

Quick Details

-

Place of Origin:

-

Guangdong, China, Dongguan, China

-

After-sales Service Provided:

-

Field installation, commissioning and training, Field maintenance and repair service, Online support, Engineers available to service machinery overseas

-

Operation System:

-

PLC Touching Screen

-

Control System:

-

Automatic Manual All-in-One

-

Service:

-

OEM, Accepte Customized Order

-

Name:

-

Deposition Magnetron sputtering vacuum coating machine/ vacuum chamber

-

Sample:

-

Available

-

MOQ:

-

1 Set

-

Business Type:

-

China Manufacturer/Factory

-

Technic:

-

Multi-Arc Ion

-

Weight:

-

As Per Design

-

Certification:

-

CE, ISO

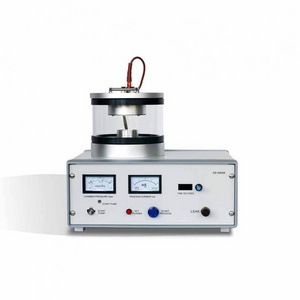

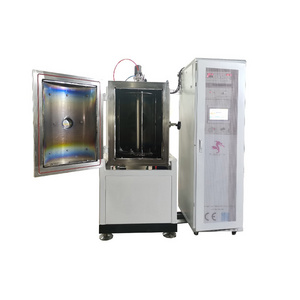

Deposition Magnetron sputtering vacuum coating machine/multi-arc ion sputtering vacuum chamber

The principle of the vacuum coating machine is based on cold cathode, self- sustained arc discharge plasma evaporation, ionization material, combine pulsed bias technical to imporve the energy and activity of deposition particles, and enhance the properties of coating on the surface of metal as well as non-metal. It can be used for metal film, such as the TiN, TiC,Zrc,CrN, Nickle, Cr and Cu etc., moreover, it can used for the other compounds film, like the Muli-layer Super-hard film, Multi-compounds film and Titanium nitride with good film.

1. A vacuum magnetron sputtering equipment, twin cathode, IF sputtering technology, and printed advanced control systems.

2. The production process all automated, continuous. Plating workpiece temperature was up to 350, adjustable temperature control district,

3. Vacuum chamber materials used SS304, polishing a vacuum chamber wall with a wall spray polishing beads processing.

4. Between the vacuum chamber separated by an independent Lord.

5. Used magnetic drive to protect the stability of transmission. The entire production line of the paragraph using VVVF speed motor drive, adjustable speed

6. Electrical control systems: Membrane touch screen and PLC automatic control, man-machine dialogue to achieve the data show that the operation and control

| Model | JTL-0910 | JTL-1110 | JTL-1311 | JTL-1612 |

| Dimension | φ900*H1000 | φ1100*H1000 | φ1300*H1100 | φ1600*H1200 |

| Main confirguration | 3 electric-arc+2 pairs of plane rectangular cathode | 6 electric-arc+2 pairs of cylindrical cathode+a pairs of plane rectangular cathode | 5 electric-arc+4 pairs of cylindrical cathode+a pairs of plane rectangular cathode | 6 electric-arc+8 pairs of cylindrical cathode+a pairs of plane rectangular cathode |

| Film type | Metal film. Compound film.reaction film.muti-layer function film. Dielectric film. Etc. | |||

| Power source | Electric arc power. DC magnetron power. MF magnetron power .Pulse basic voltage power.Ion source power | |||

| Vacuum Chamber | Vertial single(side) door. Pump system postposition.double water-cooling | |||

| Process gas control | Quality flowmeter+electromagnetism ceramic valve | |||

| Vacuum system | Diffusion pump+Roots pump+Mechanical pump+Holding Pump | |||

| Pump speed | Pumping time less than 15 minutes.from atmospheric pressure to 3*10-3Pa | |||

| Workpiece notion mode | Pubic rotation Frequency control:0-20 totation per minute | |||

| Control mode | Full automation control system PC+PLC/PC+HMI | |||

WORKING PROCESS

1.Installation and Technology:

A.We will provide 7-9 days training for free. The training will cover the general use of the system and specification on the deposition of agreed coatings

B.The seller will supply installation service when the machine arrived. The buyer should bear the Visa charge, Round-trip ticket charge and Accommodation for the engineer.

2.Warranty:

We provide 12 months warranty as from the date of delivery. The seller will arrange engineer to help with the Installing, Commissioning and Produce technic Support for free.The buyer should provide necessary assistance and cooperation, the buyer should bear the Visa charge, Round-trip tickets and Accommodation for the engineer. As the accommodation, the buyer need to supply common and safe accommodation to our engineer.