- Product Details

- {{item.text}}

Quick Details

-

Water absorption:

-

1-3%

-

COA:

-

Available

-

Al2O3 content:

-

99.5%

-

Crush strenght:

-

3500NMax

-

Bulk Density:

-

2.1-2.2 kg/l

-

Advantage:

-

High temperature-resisting

-

Size:

-

3mm-100mm

Quick Details

-

Material:

-

Alumina Ceramic

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

win-ceramic

-

Water absorption:

-

1-3%

-

COA:

-

Available

-

Al2O3 content:

-

99.5%

-

Crush strenght:

-

3500NMax

-

Bulk Density:

-

2.1-2.2 kg/l

-

Advantage:

-

High temperature-resisting

-

Size:

-

3mm-100mm

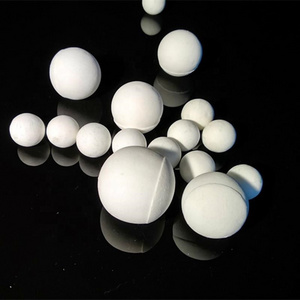

Product Display

Technical Data Sheet

Application and Features

Applications

As the supporting or covering material for catalysts, molecule sieves and dryers inside reactors and packing material towers.

As the packing in thermal storage equipment. it is used in the air separation process and functions as a kind of heat exchange

media. The requirement quickly required by heating of billet during steel rolling.

media. The requirement quickly required by heating of billet during steel rolling.

The primary purpose is to increase the gas or liquid distribution points, and support and protect less strong active catalysts.

Features

High mechanical strength; High abrasion resistance;

High thermal conductivity & thermail capacity ;

Execllent thermal stability & heat endurance.

High thermal conductivity & thermail capacity ;

Execllent thermal stability & heat endurance.

Types and Sizes

Hot Searches