- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

ZHONGHENG

-

Voltage:

-

380V 50Hz 3phases

-

Dimension(L*W*H):

-

7800mm*1.55mm*1.3mm

-

Weight:

-

4600KG

-

Usage:

-

Corrugated metal glazed tiles roofing sheets making machine

-

Tickness of coil:

-

0.3mm-0,8mm

-

Control system:

-

PLC(Delta brand)

-

Roller material:

-

45# Forged Steel with hard chrom

-

Shaft material:

-

45# Steel Outer Diameter: 75mm

-

Cutting blade material:

-

Cr 12 High Grade Steel

-

Structure:

-

400H beam

-

Main motor:

-

4kw

-

Upper speed:

-

4m

-

Forming Stations:

-

14

-

Certification:

-

CE/ISO9001

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Colored Steel

-

Production Capacity:

-

20m/min

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

ZHONGHENG

-

Voltage:

-

380V 50Hz 3phases

-

Dimension(L*W*H):

-

7800mm*1.55mm*1.3mm

-

Weight:

-

4600KG

-

Usage:

-

Corrugated metal glazed tiles roofing sheets making machine

-

Tickness of coil:

-

0.3mm-0,8mm

-

Control system:

-

PLC(Delta brand)

-

Roller material:

-

45# Forged Steel with hard chrom

-

Shaft material:

-

45# Steel Outer Diameter: 75mm

-

Cutting blade material:

-

Cr 12 High Grade Steel

-

Structure:

-

400H beam

-

Main motor:

-

4kw

-

Upper speed:

-

4m

-

Forming Stations:

-

14

-

Certification:

-

CE/ISO9001

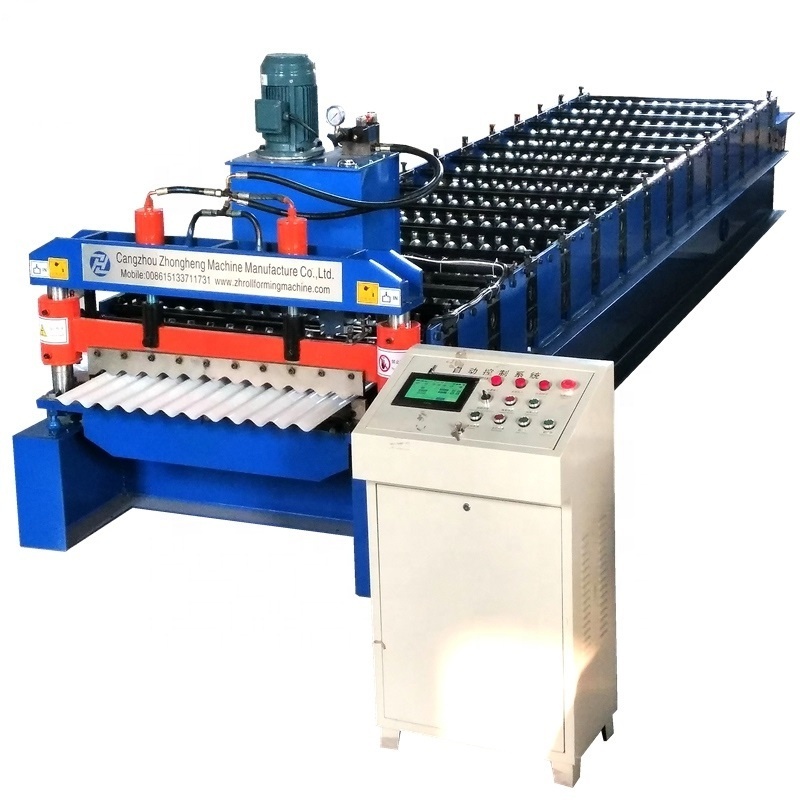

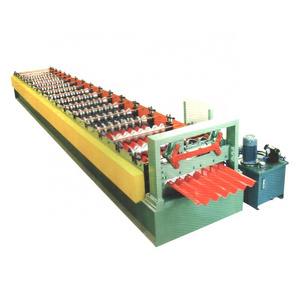

Zinc Aluminium corrugated metal glazed tiles roofing sheets making machine

As a professional manufacturer,we can make Metal Roof Tile Making Machine by customer`s demand, with a profile drawing and thickness, we can design the machine quickly.Until now,we can do many kinds of roof panel machine,such as trapezoidal sheet making machine, corrugated sheet mnaking machine, glazed tile making machine, Double Layer Roll Forming Machine and so on.

| Product Description |

|

NO. |

|

||

|

1. |

Raw material |

Type |

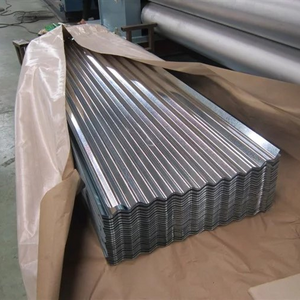

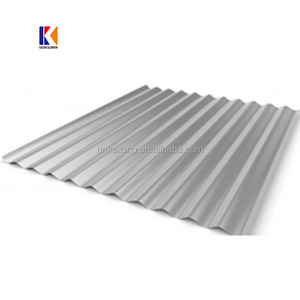

GI&PPGI |

|

Thickness |

0.3-0.8mm |

||

|

Yield strength |

235Mpa TO 350Mpa |

||

|

2. |

Decoiler |

Operation |

Manual/Hydraulic for option |

|

Weight apacity |

5tons |

||

|

3. |

Main body |

Roller station |

14-18 stations |

|

Diameter of shaft |

70mm |

||

|

Material of rollers |

45# steel with chrome 0.05mm |

||

|

Material of shaft |

45# steel with chrome 0.05mm |

||

|

Frame |

350mm H-Beam |

||

|

Chain |

1inch |

||

|

4. |

Cutter |

Operate |

Automatic hydraulic type |

|

Blade Material |

Cr12MOV |

||

|

5. |

Power |

Pump motor for cutter |

4kw |

|

Main motor |

5.5kw |

||

|

Voltage |

380V 50HZ |

||

|

6. |

Control system |

Electric Box |

PLC control system, Inverter, encoder |

|

Language |

English |

||

|

7. |

Speed |

8-12m/min |

|

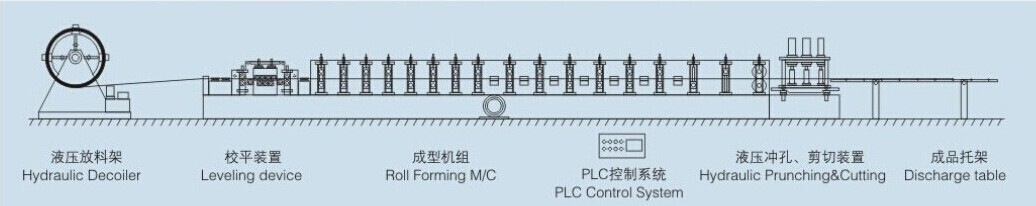

Working Process :

Decoiler—Roll Forming Machine——Hydraulic Press——Hydraulic cutter——Control System——Receiving table

Details Show

Roll Forming Machine Details

| Manual/ Hydraulic Uncoiler | ||

| Loading capacity | 5T | |

| Inner Diameter | 470-530 | |

| Coil width | 914-1250mm | |

| Speed | 15-20m/min | |

|

Feeding Table

It is used to control the width and position of the steel sheet. The sheet is guided into the machine with correct position, to make sure the panel is neat and parallel. |

|

Main Frame Material: 350 H steel Make the frame stable .

|

|

Forming Rollers Material: High grade 45# steel Roller stations: Depends on actual design |

|

Cutting system Material of blade:Cr12MOV, much better than normal Cr12 material Hydraulic power :4KW |

|

Control System Suitable power : 380V, 50Hz, 3phase or according to your need. Feature: The whole process is automatically controlled by the computer. In this way, you can ensure the accuracy and stable working. |

|

Auto Stacker/ Output table Receiving the finished panels |

| Hot Selling Machines |

| Packing & Shipping |

We provide shipping service for Zinc Aluminium corrugated metal glazed tiles roofing sheets making machine

1. Zinc Aluminium corrugated metal glazed tiles roofing sheets making machine need one 20/40 feet container to load .

2.We have professional technicians for loading to make sure machine has no damage.

3.Please provide us the nearest port name, we will ask shipping cost and arrange shipping for you.