- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220v,380v, customizable

-

Power:

-

4.45kw

-

Dimension(L*W*H):

-

1650x670x1530mm

-

Weight:

-

300 KG

-

Product name:

-

burger king chicken nugget maker line

-

Capacity:

-

2200-4200 Pcs/h

-

Diameter size:

-

≤150mm

-

Power Source:

-

Electricity 220V 380V

-

Shape:

-

customizable, variety of shapes

-

Material:

-

304 Stainless Steel

-

Package:

-

Exported Wooden Case

-

Used in:

-

Resturant, school, factory,ect

-

MOQ:

-

1 Set

-

Shipping:

-

Sea Air Express

Quick Details

-

Production Capacity:

-

2200-4200 Pcs/h

-

Place of Origin:

-

China

-

Brand Name:

-

Welly

-

Voltage:

-

220v,380v, customizable

-

Power:

-

4.45kw

-

Dimension(L*W*H):

-

1650x670x1530mm

-

Weight:

-

300 KG

-

Product name:

-

burger king chicken nugget maker line

-

Capacity:

-

2200-4200 Pcs/h

-

Diameter size:

-

≤150mm

-

Power Source:

-

Electricity 220V 380V

-

Shape:

-

customizable, variety of shapes

-

Material:

-

304 Stainless Steel

-

Package:

-

Exported Wooden Case

-

Used in:

-

Resturant, school, factory,ect

-

MOQ:

-

1 Set

-

Shipping:

-

Sea Air Express

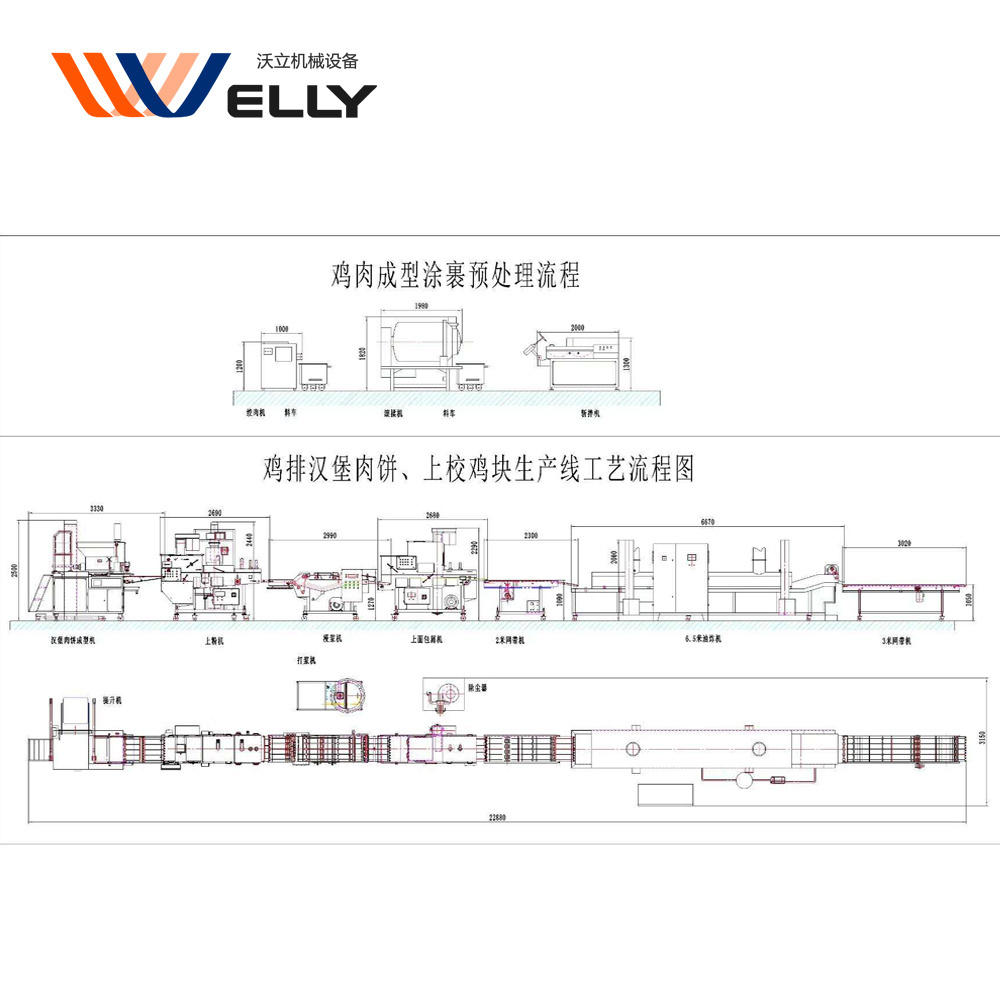

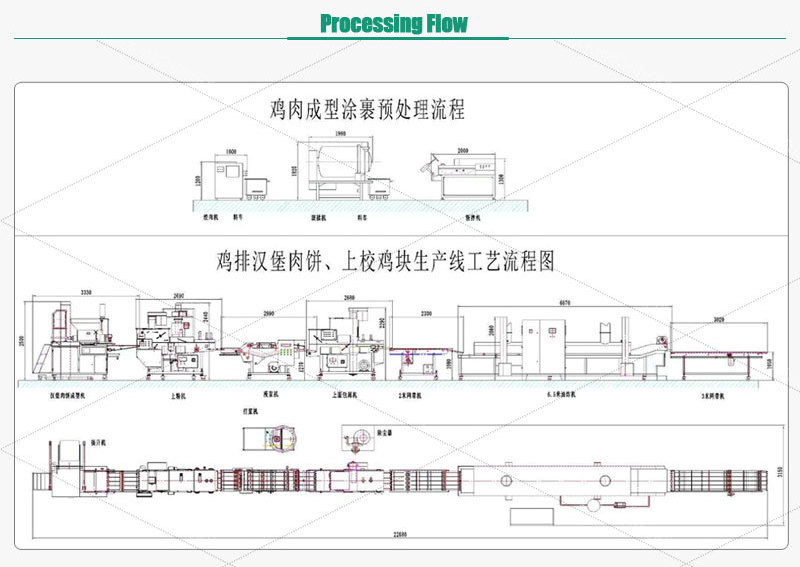

Ø Well designed meat pie equipment/ burger king chicken nugget maker line 304 stainless steel

Product Description

| Technical Data | ||||

| Name | Model | Power | Machine size | Weight |

| Patty forming machine | WYRB-300 | 1.15kw |

1650x670x1530mm |

150kg |

| Flour mixing machine | WYDJ-100 | 0.45kw |

1400x800x1600mm |

210kg |

| Starching machine | WYSJ-300 | 1.17kw |

1550x800x1250mm |

280kg |

| Bread crumbs machine | WYSK-300 | 1.65kw |

2000x800x1520mm |

170kg |

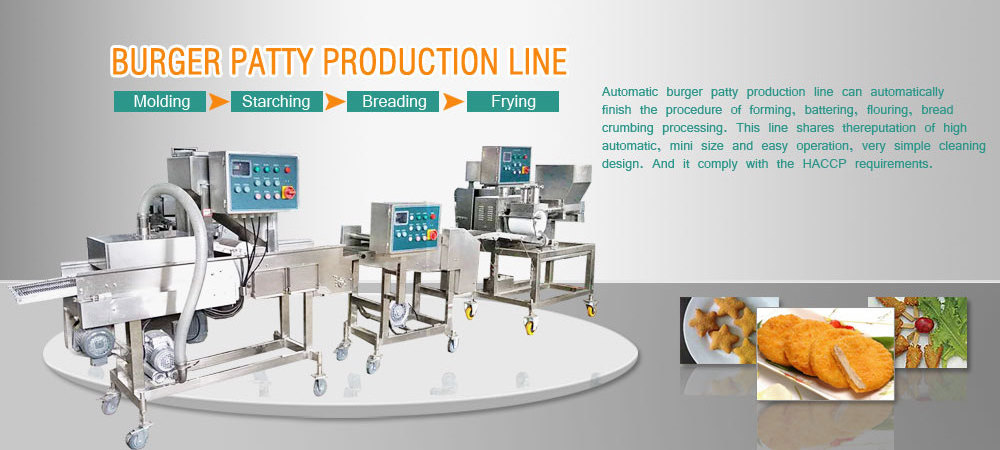

Brief Introduction

Forming Machine:

It can produce different size meat pie and cutlet by changing the forming mouth’s size and thickness.

Beating Machine: Adopt program control to realize high-speed stirring and mixing → low-speed stirring → automatic alarm circulation after the slurry is used to prevent slurry settling

Beating Machine: Adopt program control to realize high-speed stirring and mixing → low-speed stirring → automatic alarm circulation after the slurry is used to prevent slurry settling

Starching

Machine:

Automatically complete the sizing process of the product, both thin and thick. The product passes through the upper and lower mesh belts, and the slurry is covered with the slurry. The sizing product is drenched in the wind to avoid excessive slurry being brought to the next process.

Bread Crumbs

Machine:

After the product is starched into the lower belt, the bottom and side covered with bread crumbs, from the upper hopper of the bread crumbs will be covered by the upper part of the product, after the press roll pressing (the thickness of bread crumbs on the upper and lower belt can be easily adjusted), after the upper part of the wind shower, the excess bread crumbs will be blown off.

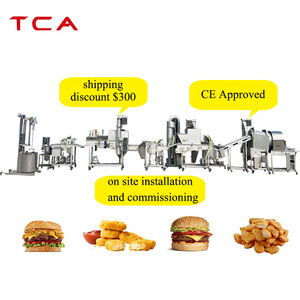

Related Products

Packaging & Shipping

Certifications

Hot Searches