- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Shengfeng

-

Voltage:

-

380V 50HZ

-

Power:

-

100kw

-

Dimension(L*W*H):

-

10m*5m*5.6m

-

Weight:

-

10000 kg

-

Working Speed:

-

80-140m/min

-

Finished Products:

-

Toilet tissue paper roll

-

Contral System:

-

PLC, Frequency converter

-

Daily Capacity:

-

5-10T

-

Drive Way:

-

Electric Motor

-

Raw material:

-

Waste paper/ Wood/Straw /Reed

-

Application:

-

Paper Industry

-

Color:

-

Optional

-

Spare Part:

-

Slef-produced

Quick Details

-

Production Capacity:

-

/

-

Processing Type:

-

paper making production line

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Shengfeng

-

Voltage:

-

380V 50HZ

-

Power:

-

100kw

-

Dimension(L*W*H):

-

10m*5m*5.6m

-

Weight:

-

10000 kg

-

Working Speed:

-

80-140m/min

-

Finished Products:

-

Toilet tissue paper roll

-

Contral System:

-

PLC, Frequency converter

-

Daily Capacity:

-

5-10T

-

Drive Way:

-

Electric Motor

-

Raw material:

-

Waste paper/ Wood/Straw /Reed

-

Application:

-

Paper Industry

-

Color:

-

Optional

-

Spare Part:

-

Slef-produced

Product Description

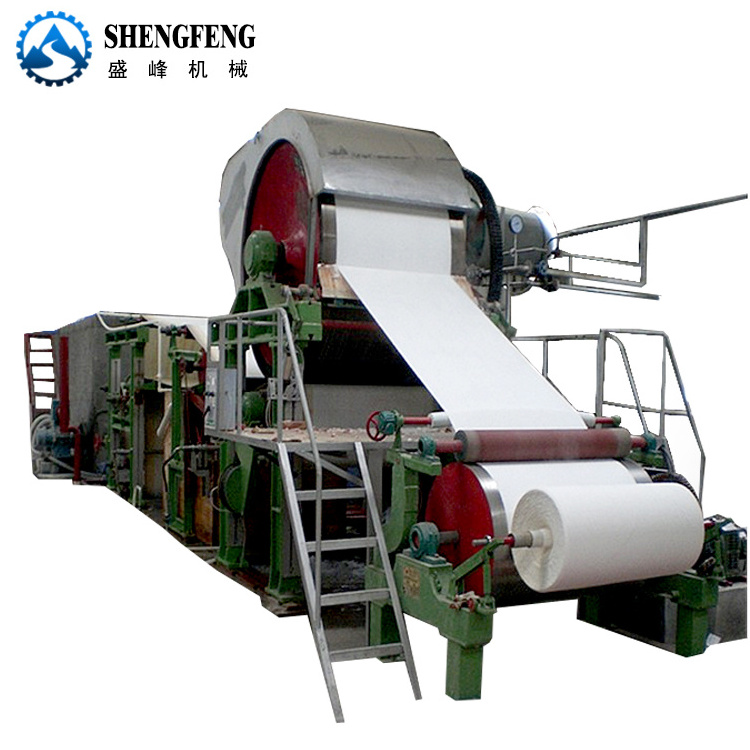

Rice straw recycling small industrial toilet paper making Manufacturing plant machine

There are many models and different capacity toilet tissue paper machine production line, Such as 787/1092/1575/1880/2000/2400/3600 model and so on. The toilet paper rolls making machine is a set of production line from waste paper recycled/vigin pulpboard to finished paper, also called:industrial toilet paper small paper making machine paper manufacturing plant Rice straw recycling machine

Step 1. Raw material choose

As a loyal buyer, we all want to produce high quality finished paper. The choice of raw materials is one of the factors that determine the quality of paper.

Some clients often want to use the wheat straw, rice straw, bagasse, wood chips and banana trees as raw material. But the quality of finished paper will worse than the waste paper. This is not competitive in the market. So the best ways is to choose waste white paper, waste office paper, waste writing paper or wood pulp etc.

Step 2. Pulping making Line

Step 3. Paper Forming parts

Step 4. Paper Process Mchines

By using different paper process machine, Tissue jumbo roll can be made to tissue paper, Napkin, facial tissue, kitchen paper and handkerchief paper etc.

Specification

|

Paper machine model

|

787mm

|

1092mm

|

1575mm

|

1880mm

|

2400mm

|

2880mm

|

3200mm

|

3500mm

|

|||||||

|

Output paper width(mm)

|

787-900

|

1200

|

1750

|

1880-2000

|

2400

|

2880

|

3200

|

3500

|

|||||||

|

Gauge(mm)

|

1300

|

1800

|

2400

|

2800

|

3400

|

3800

|

4200

|

4500

|

|||||||

|

Capacity(T/D)

|

0.8-1

|

1.5-3

|

3-5

|

5-7

|

6-8

|

8-10

|

8-10

|

10-15

|

|||||||

|

Cylinder mould Specification(mm)

|

φ 700

|

φ 1000

|

φ 1250

|

φ1500

|

φ1500

|

φ1500

|

φ1500

|

φ1500

|

|||||||

|

Dryer Specification(mm)

|

φ1000

|

φ1500

|

φ1500

|

φ2500

|

φ2500

|

φ2500

|

φ2500

|

φ2500

|

|||||||

|

Work speed(m/Min)

|

20-40

|

20-80

|

100-150

|

100-180

|

150-200

|

150-200

|

150-200

|

150-200

|

|||||||

|

Raw material

|

Straw, Waste paper, wood pulp etc

|

|

|

|

|

|

|

|

|||||||

|

Output paper style

|

Jumbo paper roll

|

|

|

|

|

|

|

|

|||||||

|

Paper weight

|

15-40g/m2

|

|

|

|

|

|

|

|

|||||||

|

Drive mode

|

Reduce drive(250type reducer)

|

|

|

|

|

|

|

|

|||||||

|

Warranty

|

12months

|

|

|

|

|

|

|

|

|||||||

|

Time of delivery

|

15-30days

|

|

|

|

|

|

|

|

|||||||

Packing & Delivery

EXPORT PACKAGING ASPECT

Large machines are different from small machines. Their export packaging is stricter than small products. In order to avoid collisions during transportation, we wrap the outer layers of the machine with wood chips and wrap them in plastic film. In order to save space in the container, we package the sporadic parts together. Installed in a spare place in the container

.

SHIPPING YOU CAN CHOOSE

By the same token, some countries have marine transportation business, then we use the most economical and safe marine transportation. However, there are no ports near some countries, so you can use adjacent ports or rail transportation, which will save some costs.

Customer Photos

Hot Searches