- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Gainjoys

-

Dimension(L*W*H):

-

700*380*480(m)

-

Weight:

-

120 KG

-

Marketing Type:

-

Other

-

Warranty of core components:

-

1 years

-

Model:

-

100*60

-

Applicable materials:

-

Mineral

-

Application area:

-

Laboratory teaching

-

Throughput:

-

50-300(kg/h)

-

Spindle speed:

-

300(r/min)

-

Feed particle size:

-

≤45(mm)

-

Discharge particle size:

-

5(mm)

-

Maximum material hardness:

-

Grade 10

-

Principle:

-

Sample preparation pulverizer

Quick Details

-

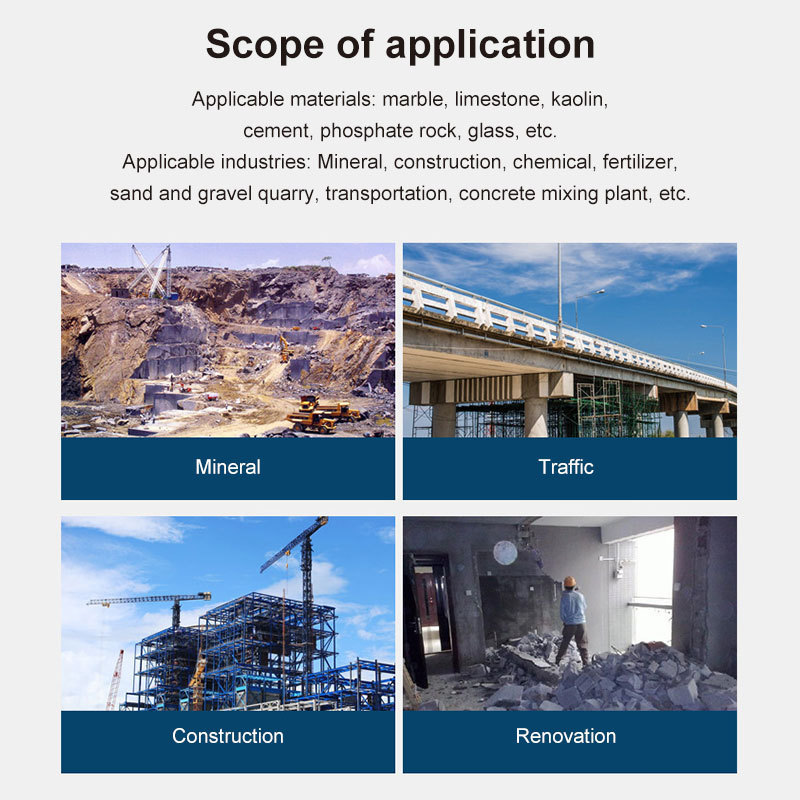

Application:

-

Mineral, construction, chemical, etc

-

Capacity(t/h):

-

50-300(kg/h)

-

Place of Origin:

-

China

-

Brand Name:

-

Gainjoys

-

Dimension(L*W*H):

-

700*380*480(m)

-

Weight:

-

120 KG

-

Marketing Type:

-

Other

-

Warranty of core components:

-

1 years

-

Model:

-

100*60

-

Applicable materials:

-

Mineral

-

Application area:

-

Laboratory teaching

-

Throughput:

-

50-300(kg/h)

-

Spindle speed:

-

300(r/min)

-

Feed particle size:

-

≤45(mm)

-

Discharge particle size:

-

5(mm)

-

Maximum material hardness:

-

Grade 10

-

Principle:

-

Sample preparation pulverizer

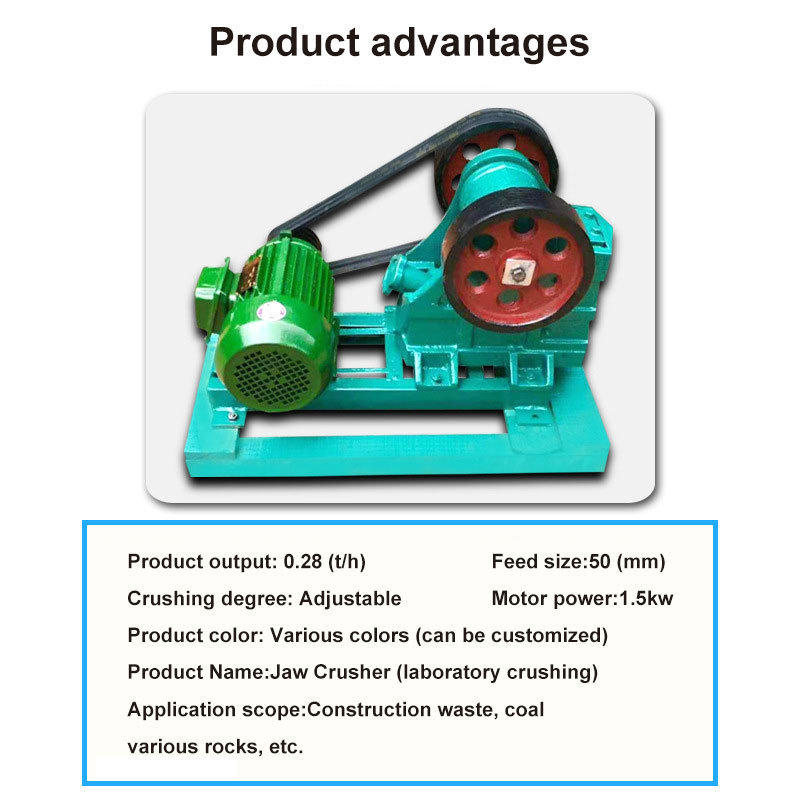

Product display

PE series Jaw Crushers

Our Jaw Crushers are ideally suitable for primary and secondary crushing, with well-capacity and high-efficiency, they are widely used for crushing various medium hard rocks and other ore materials whose maximum pressure-withstanding is 2000 kilogramforce/cm3 and they are mainly supplied to the departments like Geological coal char、Mine、Metallurgy、Chemical Engineering、Construction

Materials etc. And the labs of junior college academies science and research units.

|

Item

|

Laboratory jaw crusher

|

|

Model

|

100*60

|

|

Applicable materials

|

Mineral

|

|

Application area

|

Laboratory teaching

|

|

Throughput

|

50-300(kg/h)

|

|

Spindle speed

|

300(r/min)

|

|

Feed particle size

|

≤45(mm)

|

|

Discharge particle size

|

5(mm)

|

|

Overall dimensions

|

700×380×480(m)

|

|

Weight

|

120(kg)

|

|

Degree of crushing

|

Intermediate crusher

|

|

Maximum material hardness

|

Grade 10

|

|

Contact Us

|

Laboratory Jaw Crusher Overview

Jaw crusher is mainly used to crush a variety of ores and bulk materials with compressive strength of

less than 320Mpa in middle granularity. Sery of lab jaw crusher has full specification, its feed size of

materials ranges 125mm ~ 1200mm, and it is the preferred primary crushing equipment.The equipment is

mainly applied to crush materials in rough, medium and fine scale such as ore limestone, calcium carbide,

carbide slag , shale , basalt, river gravel, bluestone , etc. The machine has a significant performance in

cemnet plants,gravel plants,stones factory,thermal power plants desulfurization,calcium carbide plant,

and it is widely used in mining, metallurgy, chemical industry, building materials, water conservancy,

transportation and other industries.

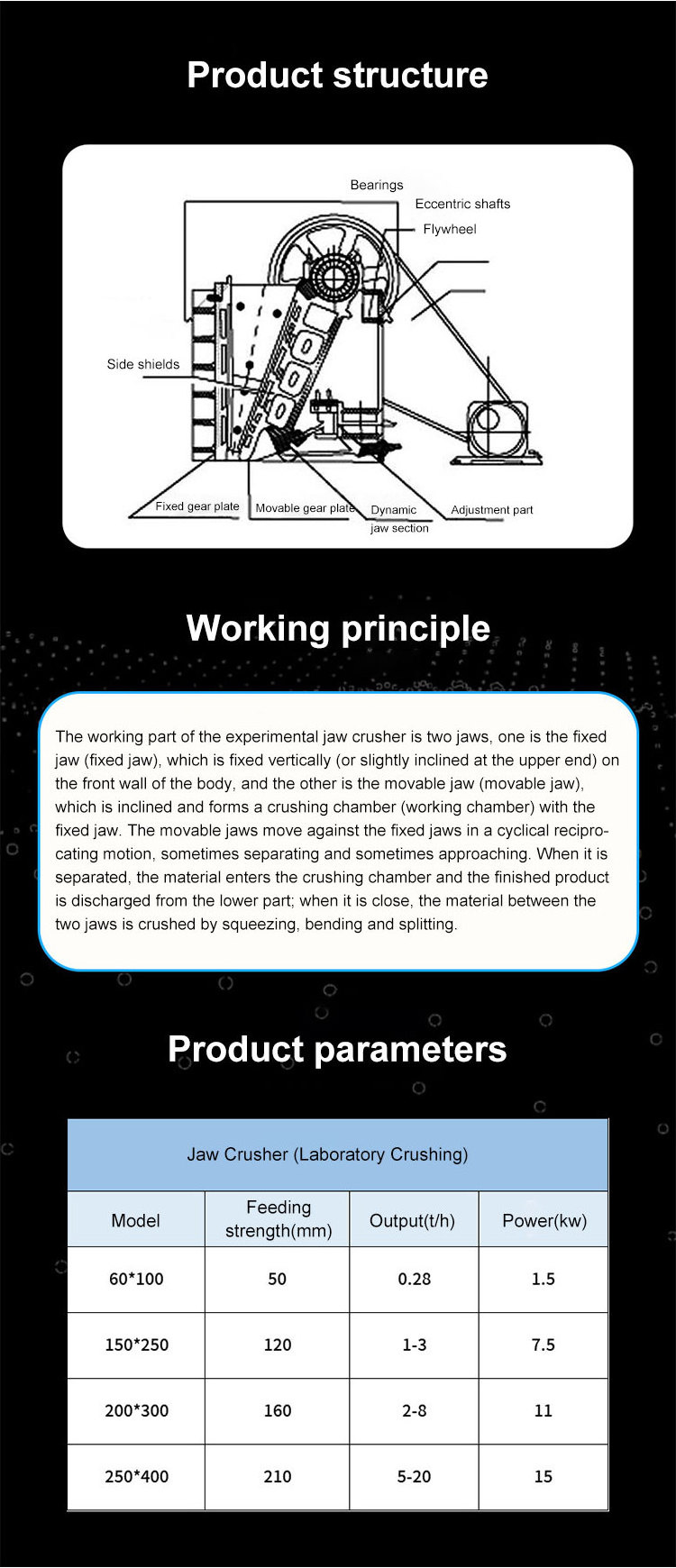

Working Principle of Lab Jaw Crusher

The main structure of lab jaw crusher: frame,eccentric shaft,big pulley,flywheel,side guard,elbow

board,elbow board seat,adjusting screw rod,the return spring,fixed board and adjusted jaw board, and

the elbow board can play a role as Protector.The broke drive model of this series jaw crusher is curved

extrusion. Motor-driven belt and pulley,through the eccentric shaft to let the jaw up and down , when the

movable jaw rises bracket, and the angle Motor-driven belt and pulley , through the eccentric shaft to

move jaw up and down movement , when the movable jaw rises,the angle between elbow board and

movable jaw plate becomes larger,thus promoting the movable jaw plate close to the fixed jawplate,while

the material can be crushed by squeezed, rubbing, grinding.When the movable jaw fall down,the angle

between elbow board and movable jaw becomes smaller,the movable bard will leave the fixed jaw board

by the action of rod and spring,at the same time crushed material is dicharge through crushing chamber.

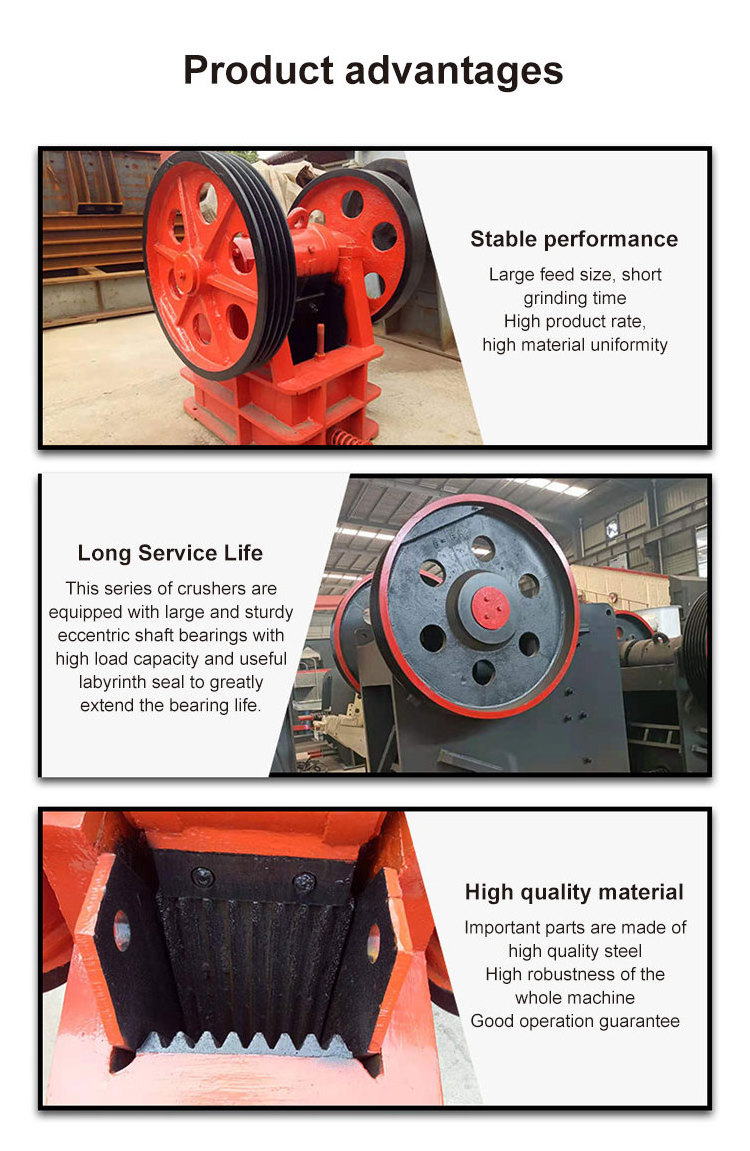

Features of Lab Jaw Crusher

1.The crushing ratio can reach to about 15 in uniform size ;

2.Adopt gasketed nesting population adjustment device,the adjusting range is big and reliable operation;

3.High efficiency, low energy consumption, compared with common small jaw crusher, it's processing

capacity 20-35% higher than that of the same specification ,and can reduce the energy consumption of 15- 20%;

4.Deep crushing chamber has no dead zone and can increase th feed ability and production capacity.

5.The use of small wear hyperboloid jaw plate,can make jaw plate service life can be prolonged by more than 3-4 times in the same process conditions,,especially to the high abrasive material is more obvious;

6.The lubrication system is safe and reliable, convenient replacement parts, maintenance workload is small.

Hot Searches