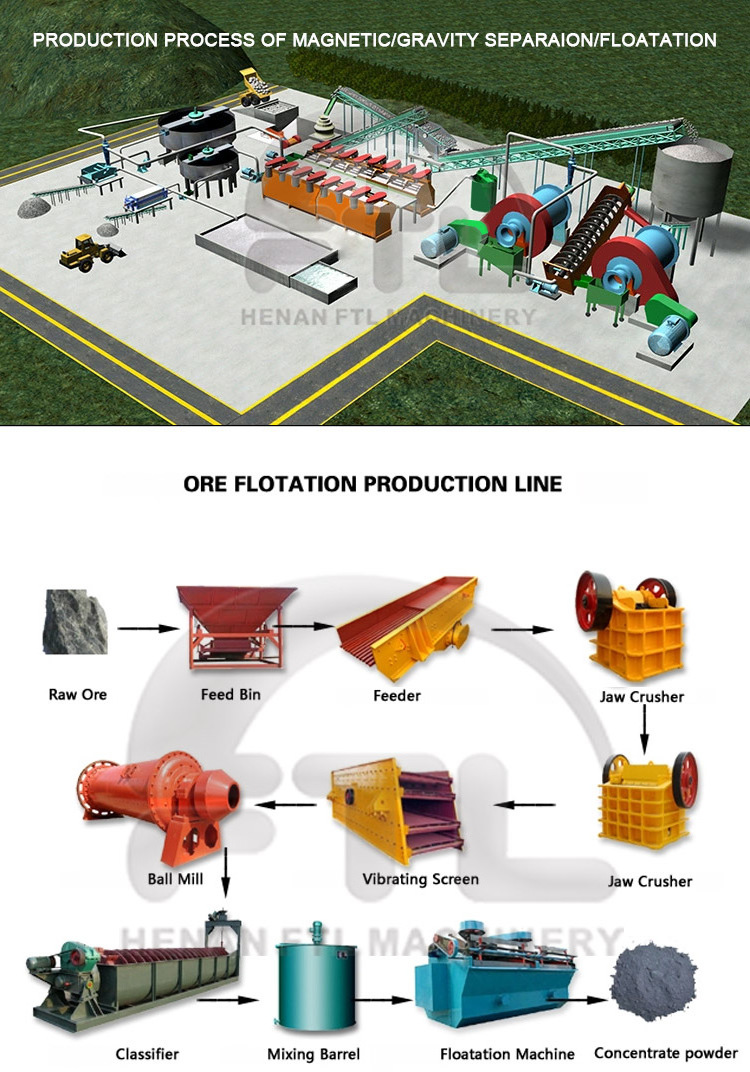

Raw material ores is exploited from mountain are big size,so it is necessary to crush firstly,in this process,the raw materials will be feed into primary crusher by feeder,then come into secondary crusher.The materials will go into screen after first and secondary crusher, the suitable size material (≤25mm) will go to next step. Oversize(>25mm) material will go back to secondary crusher to crush again. This forms a closed crush circuit.

In this process, material will be grinded into suitable sizes (about 200 mesh) for beneficiation.After grinding material will come to classifier. In classifier, suitable size material will go to next step. Coarse material will go back to ball mill for grind again. This process is a closed grind circuit.

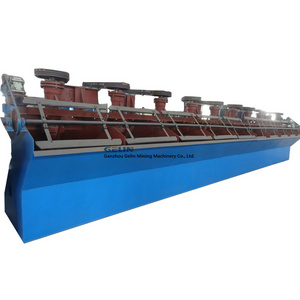

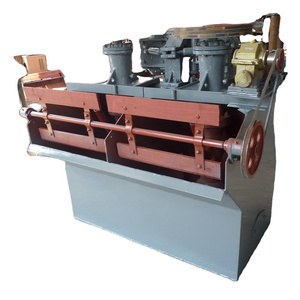

In this process, materials will be separated by flotation, magnetic separator or gravity concentrating machine. We will get the materials that we need.

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220

-

Dimension(L*W*H):

-

According to capacity

-

Weight:

-

According to capacity

-

Application:

-

Mineral Processing Plant

-

Keywords:

-

Ore Dressing Machine

-

Feeding size:

-

25mm

-

Function:

-

Screening\separation\sorting\sieving

-

Main Equipment:

-

ball mill, flotation machine, thickener,

-

Capacity:

-

0.2 - 8 M3/min

-

After sale service:

-

Engineer Overseas Service

-

Raw material:

-

iron, gold, copper, iron ore

-

Color:

-

Customers' Requirements

-

Installation:

-

Engineer Guide

-

Certification:

-

CE ISO

Quick Details

-

Production Capacity:

-

0.2-8 m3/min

-

Place of Origin:

-

China

-

Brand Name:

-

FTL

-

Voltage:

-

220

-

Dimension(L*W*H):

-

According to capacity

-

Weight:

-

According to capacity

-

Application:

-

Mineral Processing Plant

-

Keywords:

-

Ore Dressing Machine

-

Feeding size:

-

25mm

-

Function:

-

Screening\separation\sorting\sieving

-

Main Equipment:

-

ball mill, flotation machine, thickener,

-

Capacity:

-

0.2 - 8 M3/min

-

After sale service:

-

Engineer Overseas Service

-

Raw material:

-

iron, gold, copper, iron ore

-

Color:

-

Customers' Requirements

-

Installation:

-

Engineer Guide

-

Certification:

-

CE ISO

Products Description

Iron Ore Beneficiation Process plant for whole sale /

Gold wash plants , main machinery ball mill, flotation machine, Disc Vacuum Filter, thickener, magnetic separator

Process introduction

Process

Henan Fantianliang Machinery Co., Ltd.offers turnkey solutions for Ore Dressing Plant. We are one of the leading project suppliers for Ore Dressing Plant and we work closely with our customers to fulfill their specific needs for a customized packaged solution. Specialized in the fabrication of these machines for decade and this enables us to be in a leading position in the field of Ore Dressing Machine.

the requirements of transportation and smelting.

Packing and shipping

Product Paramenters

|

Equipment

|

Size

|

QTY

(set) |

Power

(kW) |

Remarks

|

|

Chute feeder

|

980×1240

|

1

|

7.5

|

|

|

Jaw crusher

|

PE600×900

|

1

|

75

|

Cast steel rack

|

|

Fine jaw crusher

|

PEX250×1200

|

2

|

37

|

Cast steel rack

|

|

Vibrating feeder

|

DZ-5

|

2

|

0.75×2/set

|

|

|

Ball mill

|

GM2.7×3.6

|

1

|

475

|

|

|

Spiral classifier

|

FLG-3000

|

1

|

30

|

|

|

Magnetic separator

|

CTB-1024

|

1

|

5.5

|

2500gs

|

|

Magnetic separator

|

CTB-1021

|

2

|

4/set

|

1400~1800gs

|

Hot Searches