- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Electronic

-

Width:

-

Customer's Request

-

Grade:

-

C17200, C17000

-

Model Number:

-

C17200

-

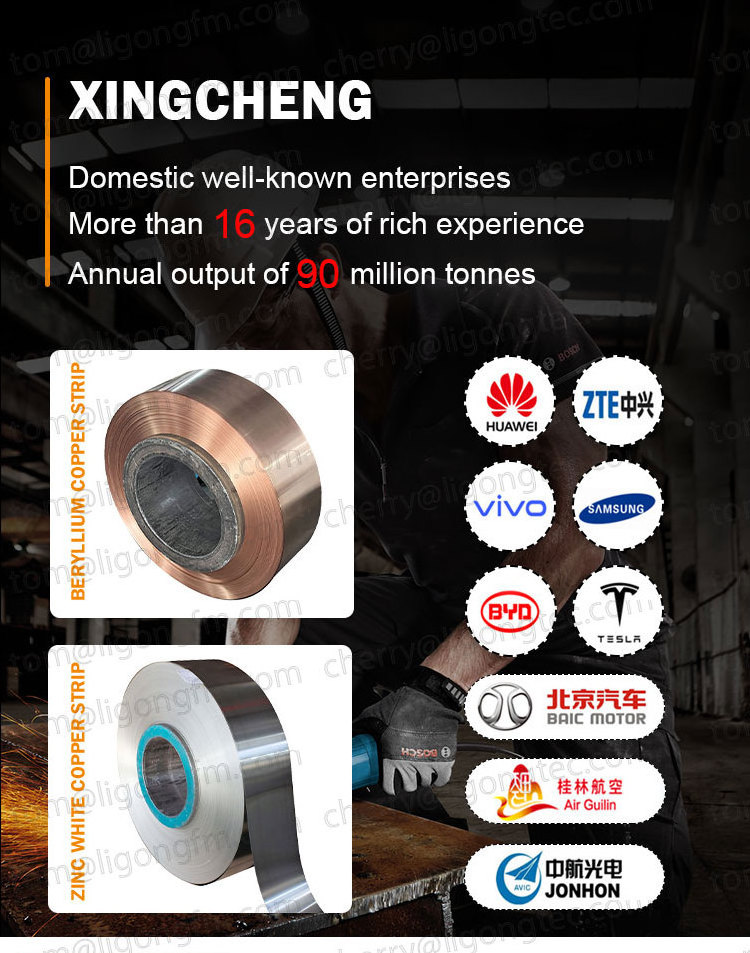

Brand Name:

-

Xingcheng

-

Place of Origin:

-

Jiangsu, China

-

Product name:

-

C1720

-

Keywords:

-

C1720 beryllium copper sheet

-

Certificate:

-

BV or as required

-

Feature:

-

good

-

Standard:

-

ANSI

-

Color:

-

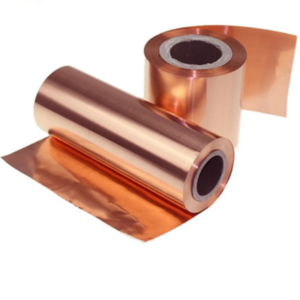

Bright surface

-

MOQ:

-

200kG

-

Surface:

-

No.1,2B,BA,No.4,Mirror

Quick Details

-

Material:

-

Bronze

-

Cu (Min):

-

99.90%

-

Alloy Or Not:

-

Is Alloy

-

Application:

-

Electronic

-

Width:

-

Customer's Request

-

Grade:

-

C17200, C17000

-

Model Number:

-

C17200

-

Brand Name:

-

Xingcheng

-

Place of Origin:

-

Jiangsu, China

-

Product name:

-

C1720

-

Keywords:

-

C1720 beryllium copper sheet

-

Certificate:

-

BV or as required

-

Feature:

-

good

-

Standard:

-

ANSI

-

Color:

-

Bright surface

-

MOQ:

-

200kG

-

Surface:

-

No.1,2B,BA,No.4,Mirror

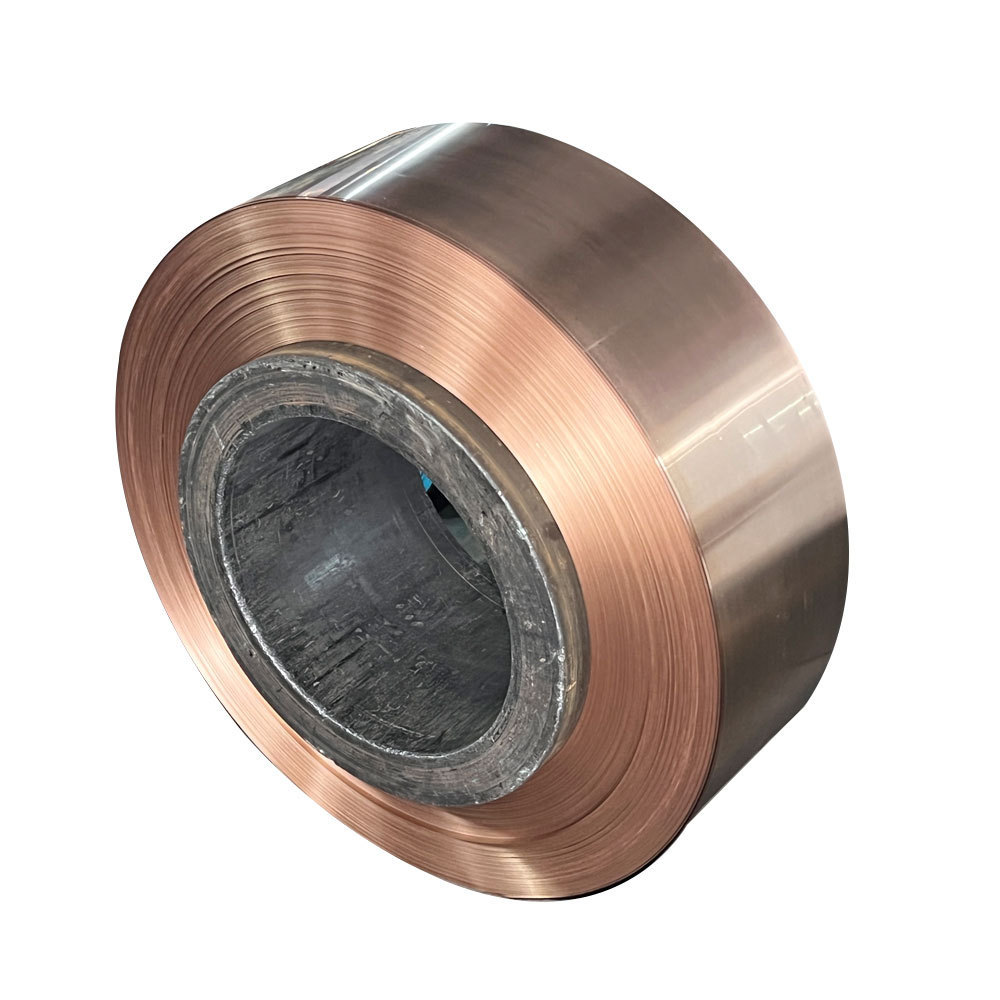

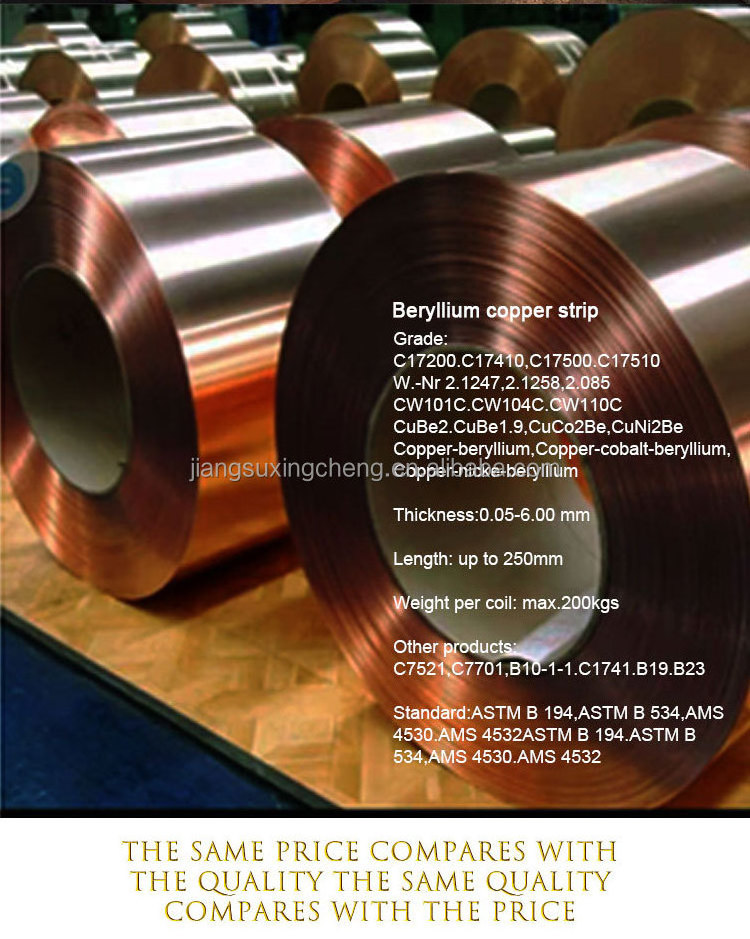

Beryllium copper strip, plate, module

Main use: Beryllium copper strip material is widely used in all kinds of micromotor brushes, switches, relays, mobile phone batteries, springs, connectors, temperature controllers spring sheet requiring high strength, high elasticity, high hardness, high wear resistance.

Features: 1. Strength: Through age hardening, the tensile strength of 1500N/mm² can be reached, so it can be used as an elastic material that can withstand high bending stress.

2. Electrical conductivity: According to different alloys, specifications, about 20-70% of IACS(International Annealed copper standard). It can be used as a high density current elastic material.

3. Machinability: The "aged material" before the age hardening treatment can be complex forming processing, and the B and S ways of the hardened material in the factory without post-processing heat treatment are materials with good balance of strength and formability.

4. Fatigue resistance: It has excellent fatigue resistance (can be repeatedly operated), and is widely used in parts with long life and high reliability.

5. Heat resistance: Because the stress relief rate in high temperature environment is still very small, it can be used in a large temperature range.

6. Corrosion resistance: It is a material that has better corrosion resistance than white copper in copper alloys and is almost unaffected by environmental corrosion changes.

Mechanical Properties :

|

Trade name |

Chemical composition% |

qualitative |

Tensile strength(N/mm ²) |

Percentage of elongation% |

endurance |

Hardness (HV ) |

Electric conductivity%IACS |

|

JIS |

|||||||

|

C1720 |

Be:1.8-2.0 Ni+Co ≥ 0.20 Ni+Co+Fe≤0.6 Cu+Be+Co+Fe ≥99.5 |

Pre-age hardening |

|||||

|

O |

410-540 |

≥35 |

— |

90-160 |

≥17 |

||

|

1/4H |

510-620 |

≥10 |

— |

45-220 |

≥16 |

||

|

1/2H |

590-695 |

≥5 |

— |

180-240 |

≥15 |

||

|

H |

685-835 |

≥2 |

— |

210-270 |

≥15 |

||

|

Post-age hardening |

|||||||

|

OT |

1100-1380 |

≥3 |

≥ 960 |

325-400 |

≥22 |

||

|

1/4HT |

1180-1400 |

≥2 |

≥1030 |

350-430 |

|||

|

1/2HT |

1240-1440 |

≥2 |

≥1100 |

360-440 |

|||

|

HT |

1270-1480 |

≥1 |

≥1140 |

380-450 |

|||

|

Extension material (standard) |

|||||||

|

OM |

685-885 |

≥18 |

≥480 |

220-270 |

≥17 |

||

|

1/4HM |

735-930 |

≥10 |

≥550 |

235-285 |

|||

|

1/2HM |

815-1010 |

≥8 |

≥650 |

260-310 |

|||

|

HM |

910-1110 |

≥6 |

≥750 |

295-345 |

|||

|

XHM |

1100-1290 |

≥2 |

≥930 |

340-390 |

|||

|

XMHS |

1210-1400 |

≥2 |

≥1030 |

360-410 |

|||