- Product Details

- {{item.text}}

Quick Details

-

Density:

-

1.00-1.20g/ml

-

PH:

-

4.5-5.0

-

Odor:

-

Slight Fermentation Odor

-

Brand:

-

Joylong

-

Model Number:

-

JLBP-107

-

Shelf Life:

-

6 Months

-

Packaging:

-

25kg/barrel

-

Load port:

-

Qingdao

Quick Details

-

Type:

-

Industrial enzyme

-

Product name:

-

Beating Enzyme for Pulping

-

Appearance:

-

Brown Liquid

-

Density:

-

1.00-1.20g/ml

-

PH:

-

4.5-5.0

-

Odor:

-

Slight Fermentation Odor

-

Brand:

-

Joylong

-

Model Number:

-

JLBP-107

-

Shelf Life:

-

6 Months

-

Packaging:

-

25kg/barrel

-

Load port:

-

Qingdao

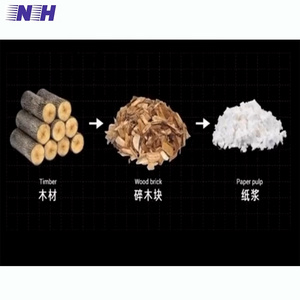

JLBP-107 Beating Enzyme for Pulping and Paper Making

Introduction:

At present, there are many issues in chemi - mechanical pulping system, such as large amount of chemicals, low pulp yield and high power consumption. JLBP-107 is a s pecific beating enzyme which is appl ied to wood (or bamboo) chips.A fter enzyme treatment, fiber structure of the pulp becomes looser, which makes the fiber swell rapidly, strengthens the binding force between the fibers, significantly reduces the refining energy consumption, and effectively improves the strength and optical properties of the mechanical pulp.The production cost can significantly decrease after the enzyme pretreatment were used during chemi-mechanical and chemical pulping process.

Specification:

|

Name |

Beating Enzyme for Pulping

|

Model |

JLBP-107 |

|

Main Ingredients |

Packing |

25kg/drum or Customized |

|

|

Appearance |

Brown Liquid |

Odor |

Slight Fermentation Odour |

|

Suitable pH |

4.0-9.0 |

Loading Port |

Qingdao |

|

Suitable Temperature |

25 °C -70°C |

Payment Terms |

T/T or L/C |

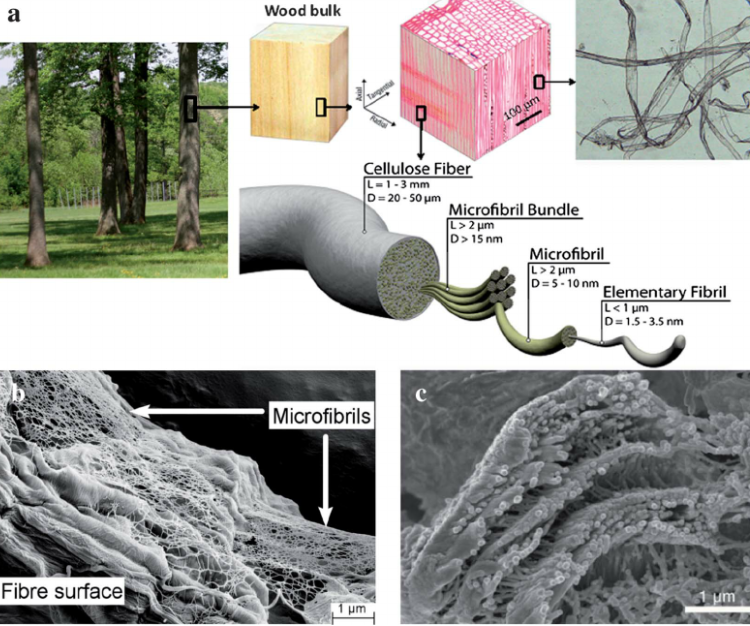

The chemical components of wood chips and bamboo chips: cellulose, hemicellulose, lignin, and other polysaccharides and resins, affect the penetration of medicinal liquid in the pulping process.

The beating enzymes consist of hemicellulose, laccase, lipase, pectinase, etc., which can partially degrade the hemicellulose cells and intercellular layer, and form microdefects in the secondary walls of cells at different levels.

After the pretreatment of wood chips and bamboo chips by biological enzyme, the adsorption capacity of raw materials to chemicals can be greatly improved, and the use efficiency of chemicals can be effectively improved.

Application method:

Spray on raw materials

Soak the raw material

1.Suitable temperature: 25 - 70 ℃

the best temperature: 40 to 60 ℃

2. Suitable pH : 4.0-9.0,optimal pH : 5.0-7.0

3. Soaking time: 60-120 minutes

4. Spraying time: 18-30 hours

Dosage: 100-300 grams/ton wood chips.

Advantages:

1.Reduce chemical usage and save energy consumption of pulping:

The pretreatment of bamboo slice raw materials can reduce the chemical use of cooking, and the amount of alkali used in cooking chemical pulp can be reduced by more than 10%. The power consumption of hot grinding of chemical machine pulp is reduced by more than 5%.Enzymatic pretreatment can increase the contact surface and adsorption capacity of lignin and effectively improve the chemicals efficiency. The amount of hydrogen peroxide can be reduced by more than 5%.

2. KP value comes down.

3.I mprove whiteness.

Cases Show:

1.A paper factory in Shandong province

Basic information:

-

Annual output: 150,000 tons of chemical pulp workshop

-

Materials used: Poplar 90%+ pine 10%

-

Pretreatment enzyme dosage: 220 g/t absolute dry pulp

|

Items |

Yield, T/ day |

Power consumption, kWh/T |

Alkali, kg/T |

H ydrogen peroxide , kg/T |

Whiteness, % |

|

Before adding enzyme |

350 |

1180 |

65.36 |

62 |

75.5 |

|

After adding enzyme |

350 |

1135 |

63.88 |

58 |

76.3 |

|

Saving quantity |

- |

45 |

1.48 |

4 |

- |

2. A paper factory in Luzhou city

Basic information:

-

Chemical pulp plant

-

Materials used: Bamboo chips

-

Pretreatment enzyme dosage: 250 g/t pulp

-

Process: enzyme treating - cooking - bleaching

The average whiteness of the pulp plate was increased by 1.8% ISO by enzymic treating

The average kappa value of pulp decreased by 0.8 after enzymatic treating

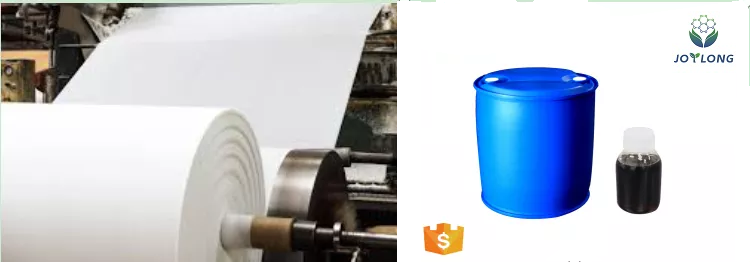

Packaging, Storage & shelf life:

Package: 25kg/ plastic drum and alternative packaging is available upon request for smaller or larger volumes. Storage: Store in a cool, dry place and away from direct sunlight.

Shelf life: Room temperature (25 ℃ ) can be stored for 6 months.