- Product Details

- {{item.text}}

Quick Details

-

Power (kW):

-

5.5

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Wire diameter:

-

3-6mm

-

Mesh width:

-

Max. 2500mm

-

Mesh length:

-

Max. 6000mm

-

Longitude wire space:

-

50-300mm

-

Cross wire space:

-

min. 25mm

-

Welding speed:

-

75 times/min

-

Voltage:

-

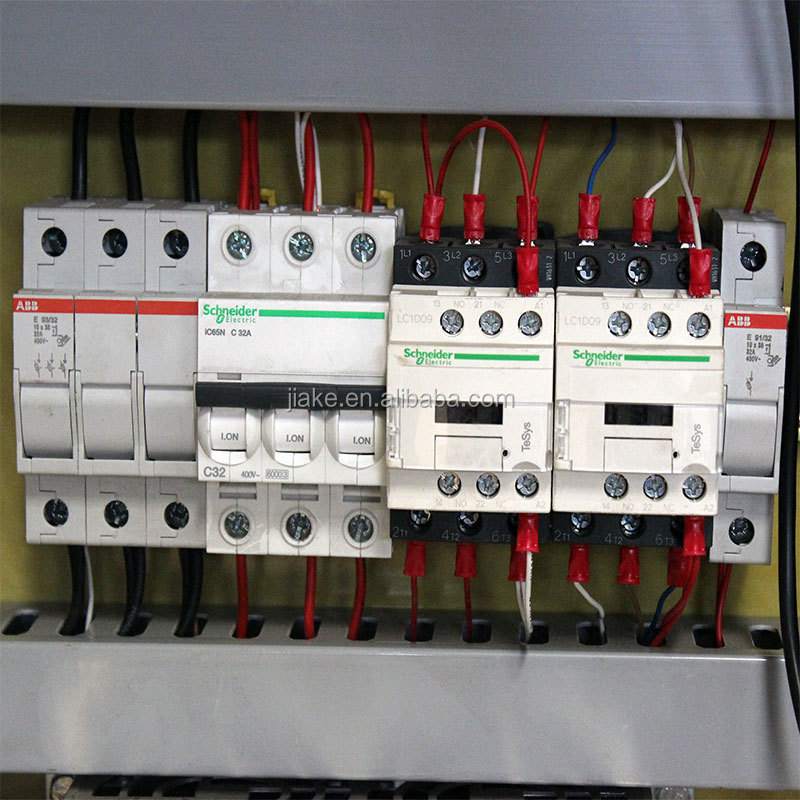

380V 50Hz 3Phase/Customized

Quick Details

-

Wire Diameter (mm):

-

3 - 6 mm

-

Place of Origin:

-

China

-

Weight (KG):

-

4200

-

Power (kW):

-

5.5

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Wire diameter:

-

3-6mm

-

Mesh width:

-

Max. 2500mm

-

Mesh length:

-

Max. 6000mm

-

Longitude wire space:

-

50-300mm

-

Cross wire space:

-

min. 25mm

-

Welding speed:

-

75 times/min

-

Voltage:

-

380V 50Hz 3Phase/Customized

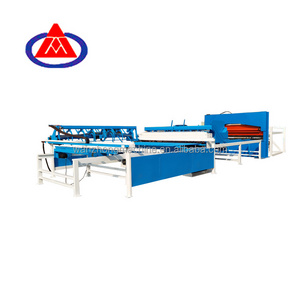

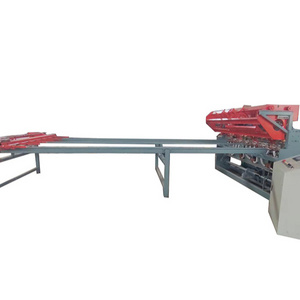

3D bending fence panel mesh welding machine production line

Detailed Description

Fence mesh welding machine, used to make fence mesh, road mesh, reinforcing mesh, shelf, explosion-proof wall etc. The mesh can be used in railway, road, airport, highway and so on.

T echnical Data

|

Model |

DP-FP-2500A |

Welding speed |

50-75 times/min |

|

Wire diameter |

3-6mm |

Welding electrode |

48PCS |

|

Line wire space |

50-300mm |

Longitude wire feeding |

Pre-straightened& pre-cut |

|

Cross wire space |

Min 25mm |

Cross wire feeding |

Pre-straightened& pre-cut |

|

Mesh width |

2500mm |

Overall size |

8400*2900*1700mm |

|

Rated power |

125kva*6 |

Weight |

3800kg |

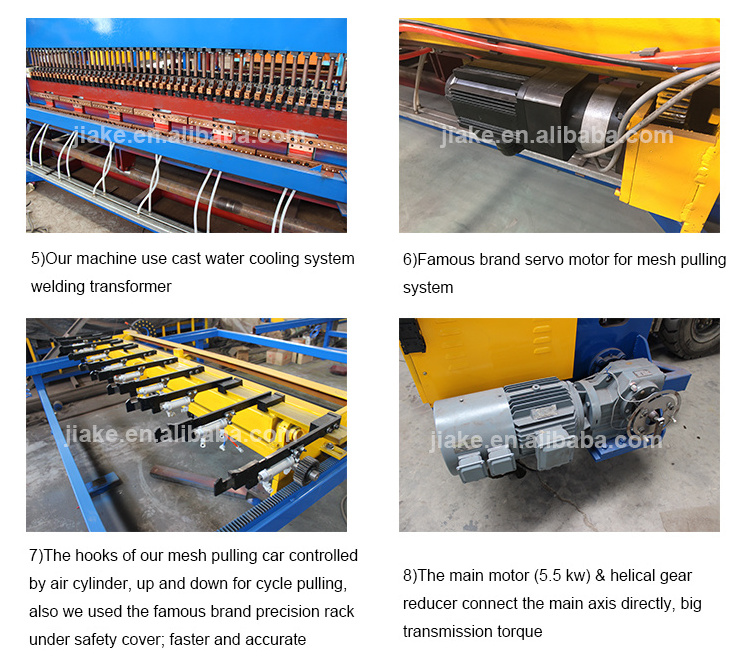

Main advantage

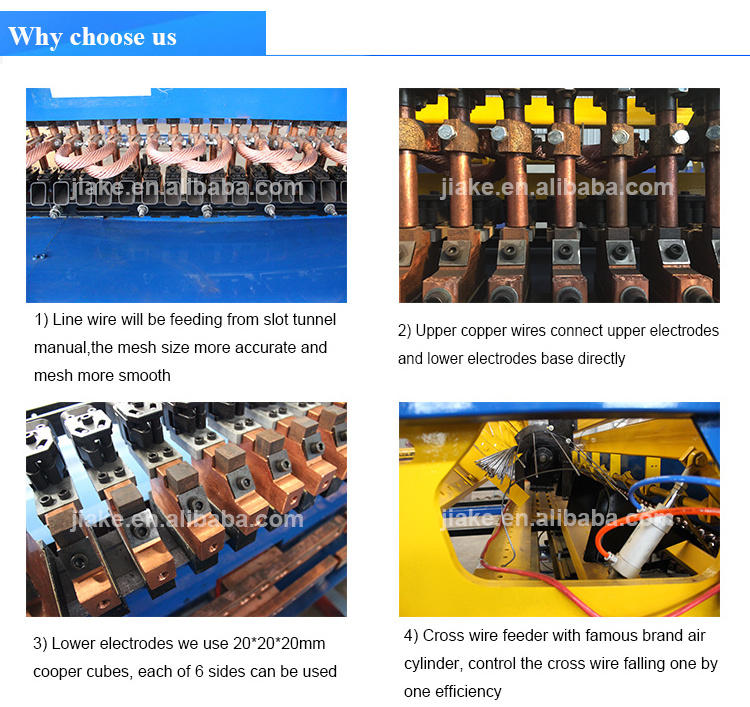

1. Panasonic, Schneider, ABB, SMC, Igus electric components.

2. Touch screen interface.

3. PLC control of cross wire space and welding current.

4. Pre-straightened & pre-cut wires.

5. Panasonic servo technology for mesh pulling.

6. Pure welding electrodes, upper Φ20*120mm, lower 20*20*20mm.

7. Water-cooling system.

8. Brake motor & reducer connect the principal axis directly.

9. High precision mesh

Machine Loaded