- Product Details

- {{item.text}}

Quick Details

-

Power:

-

Hydraulic

-

station(mold):

-

one

-

control:

-

microcomputer contro

-

Place of Design:

-

Taiwan.USA

-

Hydraulic parts:

-

Yuken Japan

-

Warranty:

-

12 months

-

Certification:

-

CE.ISO9001.EAC, ISO 9001:2000

-

Model Number:

-

SG80 iron pipe end forming machine

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Telhoo

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Power:

-

Hydraulic

-

station(mold):

-

one

-

control:

-

microcomputer contro

-

Place of Design:

-

Taiwan.USA

-

Hydraulic parts:

-

Yuken Japan

-

Warranty:

-

12 months

-

Certification:

-

CE.ISO9001.EAC, ISO 9001:2000

-

Model Number:

-

SG80 iron pipe end forming machine

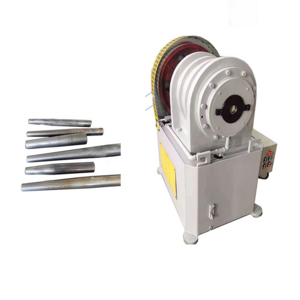

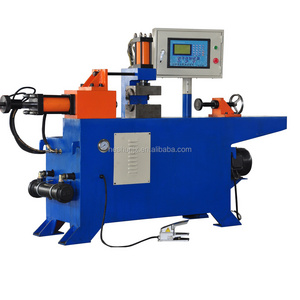

Automatic steel tube pipe end forming machine for reduce with 25 years best quality

Suitable material: Steel pip, copper pipe, aluminum pipe, stainless steel pipe etc.

Main specification

1) NC Control Unit: Easy Operation and Maintenance

2) Suitable for the shrinking of various metal pipes with different material and different shape

3) Equipped with emergency stop device. Both manual and automatic operations are available

4) Shrinking stroke 100mm. The max. workpiece length is 450mm, with no minimum workpiece length

5) Forming shapes can be convex, concave, sectional, long 7 flat, square, V-shaped, open elbow and flat elbow. The design of the tooling varies with workpiece and customers' requirements

Technical parameter

|

Type |

SG-40 |

SG-60 |

SG-80 |

SG-100 |

|

Max tube(mm) |

φ40*2.0 |

φ60*2.0 |

φ80*3.0 |

φ100*3.5 |

|

Max processing length(mm) |

110 |

130 |

150 |

180 |

|

Oil pressure(Mpa) |

14 |

14 |

14 |

14 |

|

Working speed |

100mm in3-4/s |

100mm in3-4/s |

100mm in3-4/s |

100mm in3-4/s |

|

Size(cm) |

180*45*120 |

200*50*130 |

290*70*140 |

300*75*150 |

|

Weight(kg) |

600 |

950 |

1600 |

1800 |

|

Remark |

1.The max processing length can according to customers requirement. |

|||

Telhoo Machinery established in 1991(Predecessor is QinPeng machinery manufacture factory),We start cooperation with Taiwan Well-known pipe bending machine factory since 1995, Professional develop and manufacture Pipe bending machine,Pipe cutting machine,Pipe end-forming machine,The predecessor Qinpeng machinery factory is a government-holding enterprise,In 1995 start cooperation with Taiwan well-known pipe bending machine factory and set up a new company(Telhoo Machinery)

1991 The Zhangjiagang government established Qinpeng machinery factory.

1995 Cooperate with Taiwan well-known pipe bending machine factory and set up a new company(Telhoo Machinery- “TLM” ).

1999 Buy a series of high-precision processing equipment, and become a partner of a well-known airplane manufacturer.

2002

A famous Taiwan mold designer became the CTO of our company. Also our product Successfully enter China's shipbuilding industry.

Max processing capacity to 325mm tube

.

2006 Become well-known car companies`s partner-Honda(china), Toyota(china), Volkswagen(china), changcheng(china).

2008 After many years of development and efforts, CNC pipe bending machine enter the market, Successfully as China's high-speed rail cooperation partner.

2010 Export to at least 65 countries around the world, including the United States, Russia, Poland, Mexico, Canada, Australia, England,southeast Asia,India and so on…

2013 In order to follow up 4.0 industrial trends,The technical department developed “ full automatic Robot pipe bending machine ”, “ automatic loading and feeding pipe cutting machine ” such as high efficiency pipe processing equipment.

2015 In order to better expand the overseas market,established “Telhoo holding limited” in Hong Kong.

2016 Cooperate with well-known university in China, using high-tech talent at the university for developing new products.

2017 TLM with mission and responsibility will make our product better...

1. Warranty period: We guarantee machine quality for one year, during this year, if spare parts of the machine were damaged, we can send the component to the customer by DHL, TNT freely.

2. Our factory can send our engineer to the customer’s factory install, commission and training freely. The customer provide the double trip tickets, food and accommodation for our engineer. The customer also can send the engineer to our factory to learn the operation and maintains freely.

3.Our factory provide the service for the customer forever, if the customer need operation help, can contact us by Skype, Email and Telephone at any time, we provide 24 hours on-line service. Our factory also will make DVD to show the operation steps for the customer.

1. Are you ,Manufacturer or Trading company?

A: Yes, we are

manufacturer

.

We are focuse on

metal Pipe processing machinery

since 1991

,Headquarter in Hongkong.Factory in China.

2. How to choose pipe bending machine?

A: You have to inform us following details:

- Outer diameter range

- Wall thickness range

- Bending radius (Centre Line of Radius)

- Material of Pipe

- Provide product drawings is better

3. What is the control system of the machine?

A: Standard control is Mitsubishi PLC(windows system), Special is IPC controls.

4. What is the difference between NC and CNC machines?

A: NC is standard hydraulic pipe bending machine, feeding and rotation by manual, and bending is hydraulic automatic.

CNC is fully automatic pipe bending machine, servo motor for feeding and rotation, and hydraulic or servo motor for bending, multiple tooling stack are available for two and more different bending radius (CLR).

5. What is the biggest bending capacity you can offer?

A: As of now our biggest bending capacity is 325mm outer diameter for cold bending.

6. Where is your factory located?

A: Our factory is located in Zhangjiagang City, near from Shanghai and wuxi.

Working video

http://www.youtube.com/watch?v=fKnflaueTec