- Product Details

- {{item.text}}

Quick Details

-

Injection Rate (g/s):

-

83 g/s

-

Injection Weight (g):

-

194 g

-

Screw Speed (rpm):

-

1 - 180 rpm

-

Screw diameter (mm):

-

42 mm

-

Screw L/D Ratio:

-

20

-

Distance between Tie Bars:

-

155

-

Weight (KG):

-

85000

-

Place of Origin:

-

Guangdong, China

-

Open Stroke(mm):

-

200 mm

-

Model Number:

-

TW-85V

-

Brand Name:

-

TAIWANG

-

Power (kW):

-

1 kW

-

Plastic Type:

-

Thermosetting

-

Automatic:

-

yes

-

Used for:

-

PE PET PVC

-

Opening Stroke:

-

200

-

Clamping Force (kN):

-

90

-

Certification:

-

CE

Quick Details

-

Ejector Stroke(mm):

-

200 mm

-

Ejector Force(kN):

-

3.5 kN

-

Theoretical Shot Volume(cm³):

-

215 cm³

-

Injection Rate (g/s):

-

83 g/s

-

Injection Weight (g):

-

194 g

-

Screw Speed (rpm):

-

1 - 180 rpm

-

Screw diameter (mm):

-

42 mm

-

Screw L/D Ratio:

-

20

-

Distance between Tie Bars:

-

155

-

Weight (KG):

-

85000

-

Place of Origin:

-

Guangdong, China

-

Open Stroke(mm):

-

200 mm

-

Model Number:

-

TW-85V

-

Brand Name:

-

TAIWANG

-

Power (kW):

-

1 kW

-

Plastic Type:

-

Thermosetting

-

Automatic:

-

yes

-

Used for:

-

PE PET PVC

-

Opening Stroke:

-

200

-

Clamping Force (kN):

-

90

-

Certification:

-

CE

Product Description

1.TaiWang injection molding machine is suitable for multi-purpose injection molding.

2.The following materials are suitable for our products:

GPPS, HIPS, SAN, ABS,LDPE, HDPE,PP, PPO, PA6, PA66, ACEAL COPOLYMER, CAB, PET, PBT,PC, PMMA, hard PVC, soft PVC,PU, EVA, PSF, , BMC.

3.TaiWang vertical injection machine are widely applied to produce various

terminal blocks, household appliances, consumer electronics, power tools, automotive dashboards, medical devices, open containers, cables,auto parts, Plug ,etc.

4. Overall, our vertical injection molding machines.Wide-range of materials such as

plastic, rubber, silicone could be fromed according to your requirment and available to different industry like auto, electron, medical, living goods and shoe industry.

Name: Injection unit

♦ Quick response checking valve

♦ Dual alloy 39CrMoAl screw and barrel

♦ High response and double cylinder injection system with automatic conversion function

♦ Screw back pressure control

♦ Dual alloy 39CrMoAl screw and barrel

♦ High response and double cylinder injection system with automatic conversion function

♦ Screw back pressure control

Name: Hydraulic unit

♦Top brands hydraulic parts ensure machine fast and stable

♦Visible and dischargeable oil tank, easy for hydraulic circuit maintenance

♦Top brand hydraulic pipe fits with seal, no leaking

♦High response hydraulic circuit,0.05S to reach the maximum power output

♦Visible and dischargeable oil tank, easy for hydraulic circuit maintenance

♦Top brand hydraulic pipe fits with seal, no leaking

♦High response hydraulic circuit,0.05S to reach the maximum power output

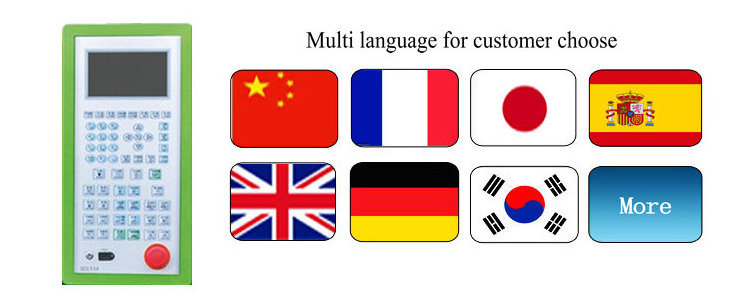

Name: Electric Unit

♦ Top brands electric parts supporting

♦ High class color screen controller

♦ Three color tower light with alarm

♦ Euro standard safety standard

♦ High class color screen controller

♦ Three color tower light with alarm

♦ Euro standard safety standard

OUR SERVICES

|

Choose TAIWANG brand liquid silicone injection molding machine,means choose a one-stop provider. From material to finished product,we can find the total solutions at TAIWANG.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1. Give suggest to choose suitable material with good price.

2. Help customer make mold design and manufacturing mold .

3. According to customer requires, give machine solution,including whole produce line.

4.Give training to customer operation machine .

5. Help customer buy product necessary accessories.

|

|

|

|

|

|

|

|

Style

|

|

|

Certificate

Related Products

The product application

automotive industry ~ aerospace industry ~ medical supplies ~ stationery supplies ~ sporting goods ~ daily necessities~electrical parts ~ hardware plastic ~ electronic parts

Company Introduction

TAIWANG

has lots of advanced machinery equipment, including all kinds of CNC machine center and inspection equipment. It has a research team including over 20 members, 40% of them have over 20 years’ industrial experience and 15% over 25 years. With these elites, our product technology is among the best in the industry all the time. During product development, TAIWANG attaches great importance to the enhancing of applications and functions so as to provide customers with higher efficiency and more convenience.

Packing&Shipping

1.Each plastic vertical injection molding machine surface with stretch film,out side with export standrand wooden box.All injection machine guaranteed to arrive well-protected.

2.We have over 10 years of export vertical injection molding machine and offer secure shiping options with reliable freight forwarders with whom we have been cooperating for many years.If you have any question or concerns about shipping and importing,juetc contact us and we will get right back to you.

3.Terms:We can offer EXW,FOB,C&F,CIF

4.Port:we are near Guangzhou and Shenzhen port

FAQ

Q:

What's can you supply?

A:

1.we can offer all series of vertical injection molding machine,support machine,material,mold,spare parts.

2.Give complete solution to customer for production and improving.

3.Offer global after sevrice,technical guidance etc.

4.Fast and convenient delivery service.

Q:

Are you vertical injection moulding machine manufacturing factory?

A:

yes,from imported core technology from German in 1981, 30 years manufacturing experience,have own R&D base in Taiwan.

Q:

Can you custom vertical injection molding machines?

A:

Yes,we can according to customer's products quality requires,output,labors condition etc,designing and custom the best suitable&economical & practical

Q:

Where are your factory?

A:

R&D Center :Taiwang Machinery(TAIWAN) Co.,LTD

Add:No.56-8,Chengong Load, Taipin City,Taiwan

Manufacturing Factory :Dongguan Taiwang Machinery Co.,LTD

Add:Chongkou Industrial district,Shijie Town,Dongguan,China.

Hot Searches