- Product Details

- {{item.text}}

Quick Details

-

Material:

-

PP,PVDF,Ss303,SS304 or SS316

-

Application:

-

Mixing

-

Working Pressure:

-

0.5- 15bar

-

Thread Size:

-

1/8'', 1/4'', 3/8'', 1/2'', 3/4'', 1'',1-1/2"

-

Thread:

-

Male Female

-

Flow Rate:

-

11.3-1540L/Min0.5-4bar

-

Marketing Type:

-

Ordinary Product

Quick Details

-

Weight (KG):

-

0.03

-

Place of Origin:

-

China

-

Product Name:

-

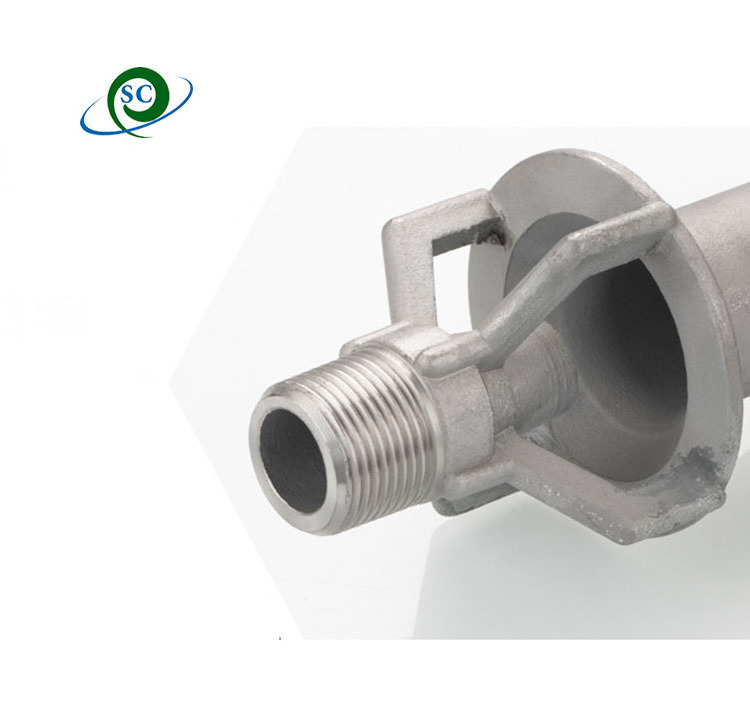

K series mixing eductor nozzle

-

Material:

-

PP,PVDF,Ss303,SS304 or SS316

-

Application:

-

Mixing

-

Working Pressure:

-

0.5- 15bar

-

Thread Size:

-

1/8'', 1/4'', 3/8'', 1/2'', 3/4'', 1'',1-1/2"

-

Thread:

-

Male Female

-

Flow Rate:

-

11.3-1540L/Min0.5-4bar

-

Marketing Type:

-

Ordinary Product

Contact us

Products Description

|

Product Name

|

K series mixing eductor nozzle

|

|

Material

|

Stainless steel(303.304.316SS), Brass

|

|

Thread Type

|

NPT, BSPT

|

|

Thread Size

|

1/8'', 1/4'', 3/8'', 1/2'', 3/4'', 1'',1-1/2"

|

|

Custom Made

|

Available

|

|

Flow Rate

|

11.3-1540L/Min0.5-4bar

|

|

Applications

|

Coating, lubricating, chemical application;

Cooling, humidifying, moistening; Cleaning, washing, rinsing; lubricating;foaming Dust controling, fire fighting;dust suppression |

Details Images

Application Scenario

Spraying a liquid through a spray nozzle can serve different purposes:

DISTRIBUTION

Engineers design nozzles with different spray distribution patterns. Patterns can be solid stream, full cone, hollow cone, flat spray, spoon flat fan. The nozzle design aims at the uniformity and impact force of the jet sprayed whether nozzles are used individually or overlapping. Below figures show detailed information for a variety of capacities and spray sections. We mark distribution on every page for your convenience.

Certifications

Hot Searches