- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V/415V

-

Power:

-

21000

-

Weight:

-

2100 KG

-

Dimension(L*W*H):

-

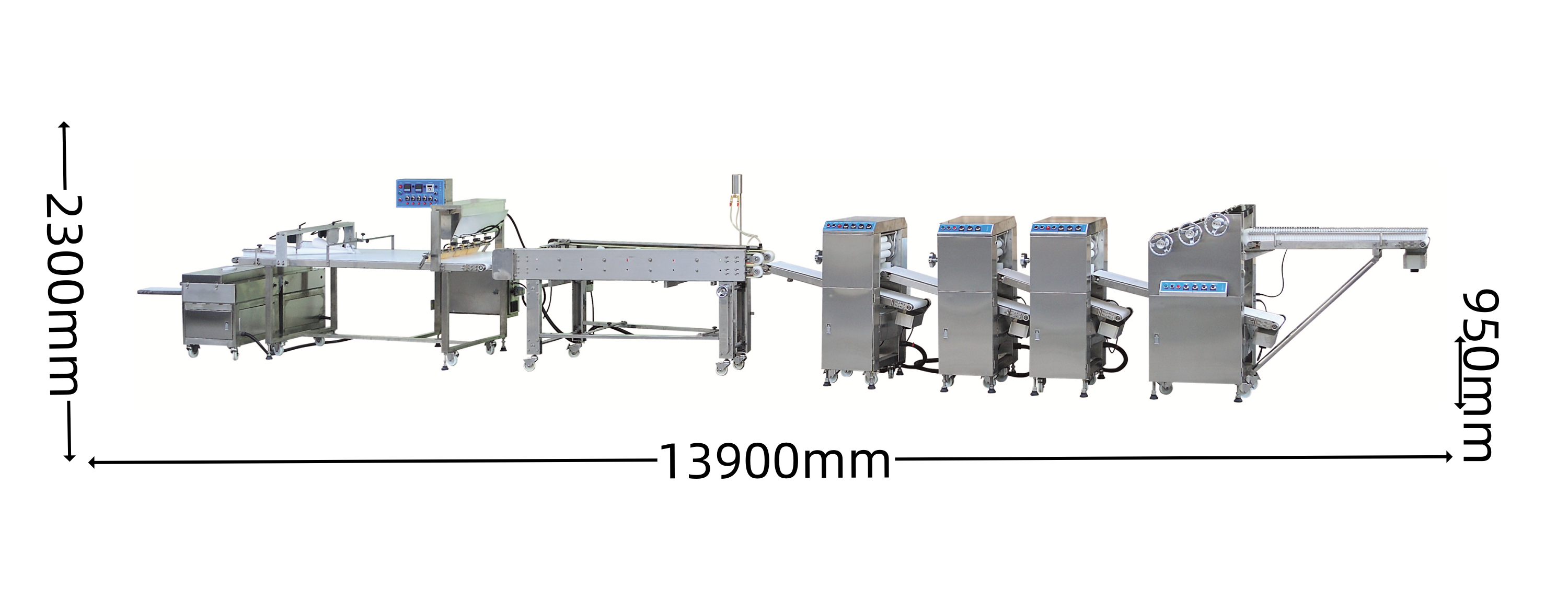

13,900mmx 950mmx 2,300mm

-

Year:

-

2023

-

Product Name:

-

Frozen Plain Paratha Dough Balls Making Machine

-

Layers:

-

32

-

Food Weight:

-

50-150g/pcs

-

Capacity:

-

5000-5500 Pcs / Hour

-

Dusting:

-

Flour ,Oil ,Scallion,Spices

-

Air consumption:

-

1,200 L/min

-

Application:

-

Lacha Paratha,Flaky scallion pancake, filo

-

Advantage:

-

Efficient, hygienic and cost saving

-

Warranty Service:

-

Online support,Spare parts

-

After Warranty Service:

-

Field maintenance and repair service

Quick Details

-

Warranty of core components:

-

1 Year & Lifetime Support

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Ying Machinery

-

Voltage:

-

220V/380V/415V

-

Power:

-

21000

-

Weight:

-

2100 KG

-

Dimension(L*W*H):

-

13,900mmx 950mmx 2,300mm

-

Year:

-

2023

-

Product Name:

-

Frozen Plain Paratha Dough Balls Making Machine

-

Layers:

-

32

-

Food Weight:

-

50-150g/pcs

-

Capacity:

-

5000-5500 Pcs / Hour

-

Dusting:

-

Flour ,Oil ,Scallion,Spices

-

Air consumption:

-

1,200 L/min

-

Application:

-

Lacha Paratha,Flaky scallion pancake, filo

-

Advantage:

-

Efficient, hygienic and cost saving

-

Warranty Service:

-

Online support,Spare parts

-

After Warranty Service:

-

Field maintenance and repair service

Frozen Plain Paratha Dough Balls Making Machine

Model No:

YZ-980

Frozen Plain Paratha Dough Balls Making Machine

only needs to feed the mixed dough into the hopper automatically by the conveyor belt, and then stretch it into a thin skin after rolling, widening and stretching. After a series of processes such as brushing oil,sprinkling green onion and spices, it is formed and rolled into a spiral dough balls.

Processing

: Dough pressing - sheeting -oil ,scallion spraying-rolling -forming -freezing -baking .

|

YZ-980

Frozen Plain Paratha Dough Balls Making Machine

|

|

|

|

|

|

|

Power Supply

|

220V/380V/415V, 3 Phase, 50/60Hz, 21Kw

|

|

|

|

|

|

Product Weight

|

50 ~ 150 g/pcs

|

|

|

|

|

|

Capacity

|

5,000~5,500 Pcs/Hour

|

|

|

|

|

|

Dimension

|

13,900mm(L)x 950mm(W)x 2,300mm(H)

|

|

|

|

|

|

Machine Weight

|

2100kgs

|

|

|

|

|

Automatic Frozen Plain Paratha Dough Balls Machine

is

designed to make various kind of

food products such as Plain Paratha ,Stuffed Paratha ,Lacha Paratha ,Aloo Paratha,Flat Bread

,Chapati,Flaky scallion pancake,Filo,Burek,etc .

* More efficient dough feeder

Incline conveyor with an automatic feeding control sensor makes the feeding process smoother.

* Maintain dough texture

4 sheeting rollers gradually roll a chunk of dough into a dough sheet to avoid too much pressure to destroy dough texture.

* Extremely thin layer

The stretching device stretches the dough sheet into 0.8 mm.

* Automatic oil feeder with temperature controller

Makes the solid fats and liquid oil drip and keep the feeder unblocked.

* Scallions sprinkled evenly

The automatic sprinkling device sprinkles chopped scallions evenly on the dough sheet.

* Conveyor designed for dough resting

The conveyor is 35 meters long to let the dough rest 8 to 10 minutes.

* Roll up dough strips for more layers

According to the dough texture and product size, install the proper weight and number of the stainless steel wire mesh for perfectly rolling up the dough strips.

* Optional machinery

Automatic Filming and Pressing Machine is available to bundle to continue pressing the roll-up dough balls and filming them for packing.

Incline conveyor with an automatic feeding control sensor makes the feeding process smoother.

* Maintain dough texture

4 sheeting rollers gradually roll a chunk of dough into a dough sheet to avoid too much pressure to destroy dough texture.

* Extremely thin layer

The stretching device stretches the dough sheet into 0.8 mm.

* Automatic oil feeder with temperature controller

Makes the solid fats and liquid oil drip and keep the feeder unblocked.

* Scallions sprinkled evenly

The automatic sprinkling device sprinkles chopped scallions evenly on the dough sheet.

* Conveyor designed for dough resting

The conveyor is 35 meters long to let the dough rest 8 to 10 minutes.

* Roll up dough strips for more layers

According to the dough texture and product size, install the proper weight and number of the stainless steel wire mesh for perfectly rolling up the dough strips.

* Optional machinery

Automatic Filming and Pressing Machine is available to bundle to continue pressing the roll-up dough balls and filming them for packing.

Hot Searches