- Product Details

- {{item.text}}

Quick Details

-

production name:

-

wool carpet washing machine

-

Name:

-

Industrial Washer Extractor

-

Product name:

-

horizontal sheep wool washing machine

-

Used for:

-

Hotel factory laundry Hospital

-

Weight:

-

260kg

-

Max washing capacity:

-

15kg

-

related machine1:

-

wool dewater machine

-

related machine2:

-

wool drying machine

Quick Details

-

Warranty:

-

1 Year

-

After-sales Service Provided:

-

Video technical support

-

Place of Origin:

-

Henan, China

-

production name:

-

wool carpet washing machine

-

Name:

-

Industrial Washer Extractor

-

Product name:

-

horizontal sheep wool washing machine

-

Used for:

-

Hotel factory laundry Hospital

-

Weight:

-

260kg

-

Max washing capacity:

-

15kg

-

related machine1:

-

wool dewater machine

-

related machine2:

-

wool drying machine

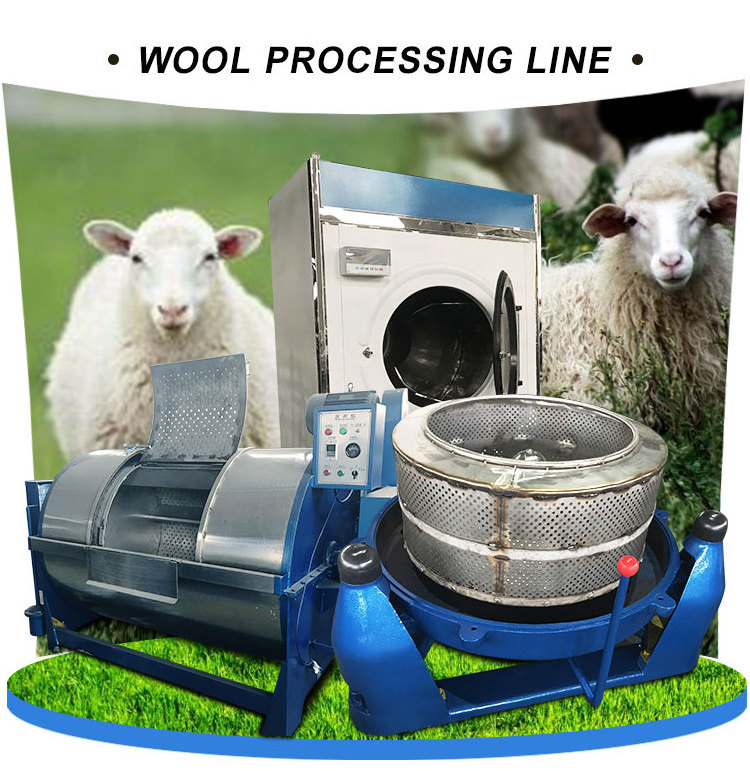

washing machine for hotel and hospital commercial washing machine laundry

wool washing machine→wo

ol dewater machine→wool drying machine

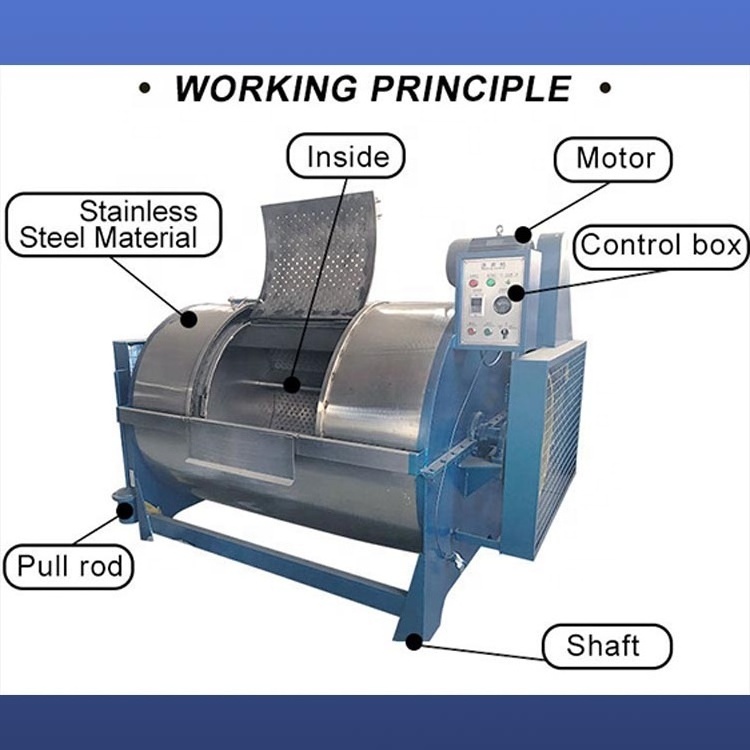

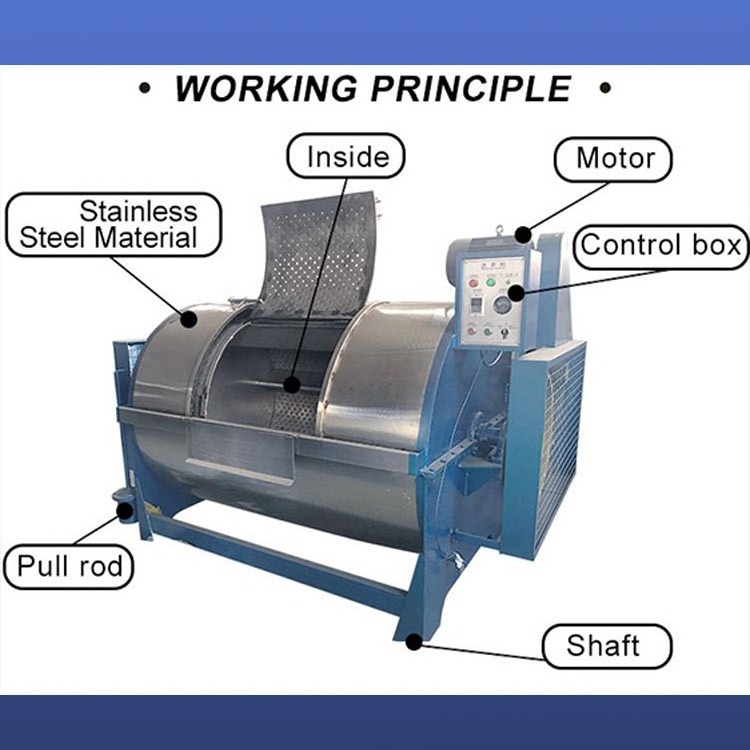

The industrial washing machine is driven by the motor to drive the inner casing through the belt shifting, and under the action of timing controller, the inner liner rotates positively and negatively, which drives water and clothes to move asynchronously, so that water and clothes can rub together to achieve the purpose of washing. The industrial washing machine is suitable for washing all kinds of fabrics such as wool, cotton, wool, hemp, chemical fiber blending, etc. It is widely used in clothing washing, hostels, schools, hospitals, hotels, blanching and dyeing factories, large and medium-sized enterprises and service fields.It is conducive to reducing labor intensity, improving work efficiency and reducing energy consumption.

1) The inner liner and outer shell of the wool washing machine are made of high quality stainless steel with high corrosion resistance.

The machine has reasonable design, smooth operation and long service life.

2) It can achieve automatic timing, large washing capacity and high efficiency.

3) According to customer needs , t he automatic washing machine has two structures of compartment type and bridge type.

4) It is suitable for washing and bleaching equipment of clothing and fabrics, such as cotton, linen, wool, chemical fibers, man-made leather, etc.

Details show:

When the machine is connected to the power supply, the power indicator lights are on, the three-switch controls to start, stop and automatic . and the indicator lights are on when the position is switched on, which can realize the opposite door to move. When the automatic position is switched on, the indicator lights are on and the washing time is selected according to the requirements of the washing process. he machine will automatically run and wash in the prescribed time.

Main parameter:

|

Model |

Max washing capacity(Kg) |

Power (kw)

|

Steam pressure (mpa) |

Dimensions (mm) |

Weight(kg) |

|

|

XGP1 5 |

15 |

0.75 |

0.3-0.6 |

1100 x 850 x 1200 |

260 |

|

|

XGP20 |

20 |

0.75 |

0.3-0.6 |

1250 x 940 x 1300 |

380 |

|

|

XGP30 |

30 |

1.1 |

0.3-0.6 |

1650 x 1100 x 1450 |

600 |

|

|

XGP50 |

50 |

1.5 |

0.3-0.6 |

2000 x 1300 x 1500 |

800 |

|

|

XGP 7 0 |

7 0 |

2.2 |

0.3-0.6 |

2050 × 1400 × 1800 |

900 |

|

|

XGP100 |

100 |

3 |

0.3-0.6 |

2350 × 1400 × 1900 |

1200 |

|

|

XGP150 |

150 |

4 |

0.3-0.6 |

2500 × 1400 × 2100 |

1500 |

|

|

XGP200 |

200 |

5.5 |

0.3-0.6 |

2940 × 1480 × 2100 |

1950 |

|

|

XGP250 |

250 |

7.5 |

0.3-0.6 |

3140 × 1500 × 2300 |

2300 |

|

|

XGP300 |

300 |

11 |

0.3-0.6 |

3514 × 1850 × 2300 |

2600 |

|

|

XGP400 |

400 |

15 |

0.3-0.6 |

4200 × 2050 × 2450 |

3400 |

|

The wo ol dewater machine is designed according to the unified national standards. It has the advantages of simple and reasonable structure, high efficiency, low wear and tear, low noise, safety and reliability. It is mainly used for dehydration and drying of various textiles, clothing, chemical raw materials and latex products after washing. The products are widely used in textiles, printing and dyeing, clothing, hotels, hospitals, chemical and latex products and other enterprises.

Features and advantages:

1). The wool dewater machine dewaterers are three-legged pendulum structure, which can effectively reduce the vibration caused by unbalanced load in the hub.

2). The shell and top cover are made of high quality stainless steel. The cage base and chassis are made of cast iron. The outlet pipe is under the chassis.

3). The spindle is made of high-quality steel after heat treatment and finishing.

4). The drive part is driven by triangular belt. The centrifugal starting wheel is driven directly by the motor, which can make the machine start slowly and gradually reach the designed speed, so as to ensure the smooth operation of the machine.

5). There is brake opening and closing arm in the machine, which has good braking performance and can make the machine stop quickly.

Main parameter:

| Model | Capacity | Power | Dimension | Weight |

| SL-500 | 25 kg/time | 1.5 kw |

1000×1000×650 mm |

250 kg |

| SL-1000 | 130 kg/time | 5.5 kw | 1800×1800×900 mm | 1100 kg |

| SL-2000 | 500 kg/time | 11 kw |

2550×1950×1400 mm |

2400 kg |

The wool drying machine belongs to cabinet structure. It has the advantages of novel shape, reasonable structure, high efficiency, low energy consumption, low noise, safety and reliability. The machine is mainly used for drying various textile fabrics, cotton, wool, chemical fiber clothing and latex products after dehydration. It is widely used in textile, clothing, printing and dyeing, hotels, hospitals, military, chemical and latex industries.

Features and advantages:

1. According to the drying requirements, the machine can be equipped with different drying temperature and time to realize drying automation.

2. The inner barrel is made of stainless steel bright plate with excellent heat resistance. The inner wall is smooth and the wear of clothes is reduced.

3. The machine is equipped with efficient radiator and reasonable air duct to make hot air contact with clothes directly, which greatly improves the efficiency of drying clothes and saves energy at the same time.

4. The large inlet port facilitates the entry and exit of clothes. The large collection of plush can not easily cause the clogging of plush and protect the smooth air passage, thus greatly improving the drying efficiency.

5. Various models of steam heating and electric heating can be selected.

Main parameter:

| Model | capacity | Power | Dimension(mm) | Weight |

| SL-15 | 15kg/time | 1.85kw | 850*100*1650 | 300kg |

| SL-30 | 30kg/time | 2.2kw | 1120*1350*1850 | 560kg |

| SL-50 | 50kg/time | 2.6kw | 1280*1750*2100 | 700kg |

| SL-100 | 100 | 3.7kw | 1500*1930*2300 | 1000kg |

| SL-150 | 150 | 6kw | 1880*2050*2750 | 1300kg |

Application scope:

1.Online /sale services:

a. super and solid quality

b.fast and punctual delivery

c.standard export package or customized

2.After - sale services:

a.assistance to build your project

b.repairing and maintenance with any problems in the warranty .

c.spare parts and wearing parts for free or with big discount

d. any feedback of the machine can be told us so that we can give you best service

3.Other cooperation services:

a. technology knowledge share

b.business expansion advising

c.video technical support