- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

1.5-2.5mm

-

Place of Origin:

-

Hebei, China

-

Voltage:

-

380V or as required

-

Weight:

-

10000 kg

-

Marketing Type:

-

Hot Product

-

Certification:

-

ISO9001 and CE

Quick Details

-

Type:

-

roll forming machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

15 m/min

-

Rolling thinckness:

-

1.5-2.5mm

-

Place of Origin:

-

Hebei, China

-

Voltage:

-

380V or as required

-

Weight:

-

10000 kg

-

Marketing Type:

-

Hot Product

-

Certification:

-

ISO9001 and CE

Product Description

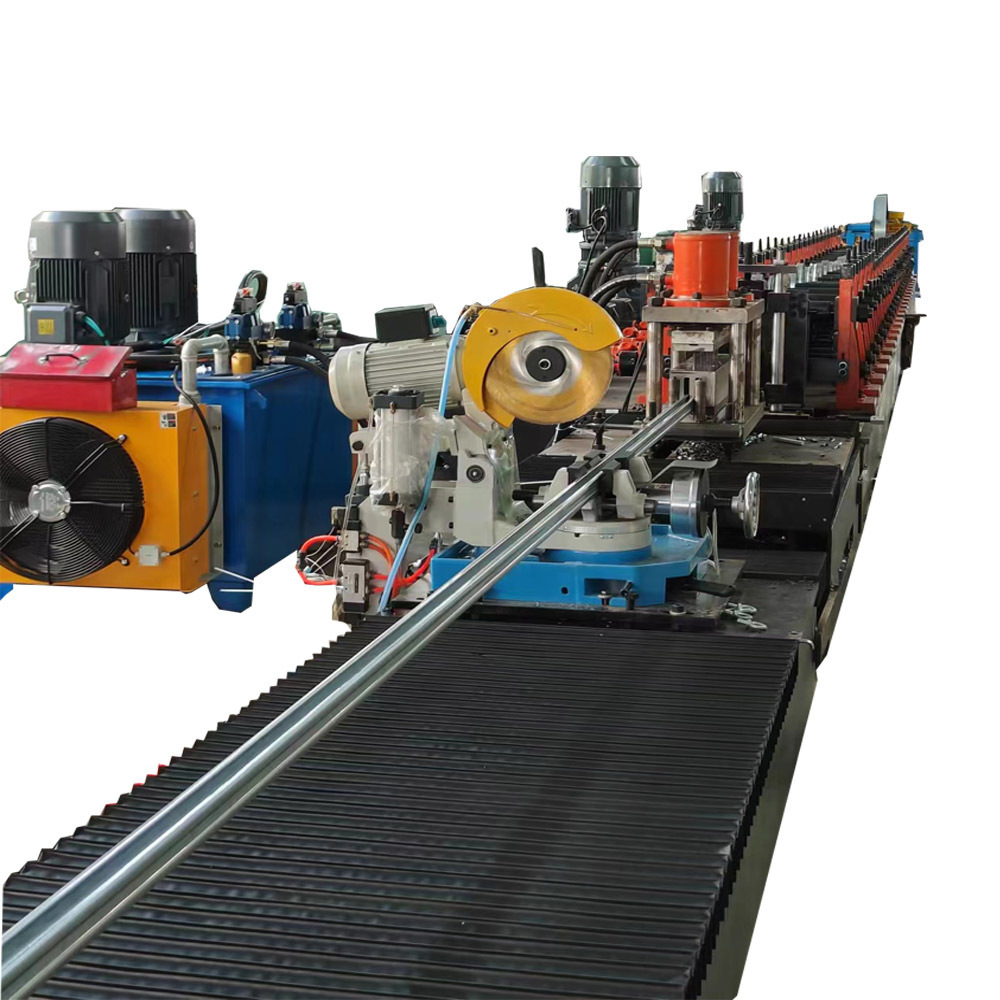

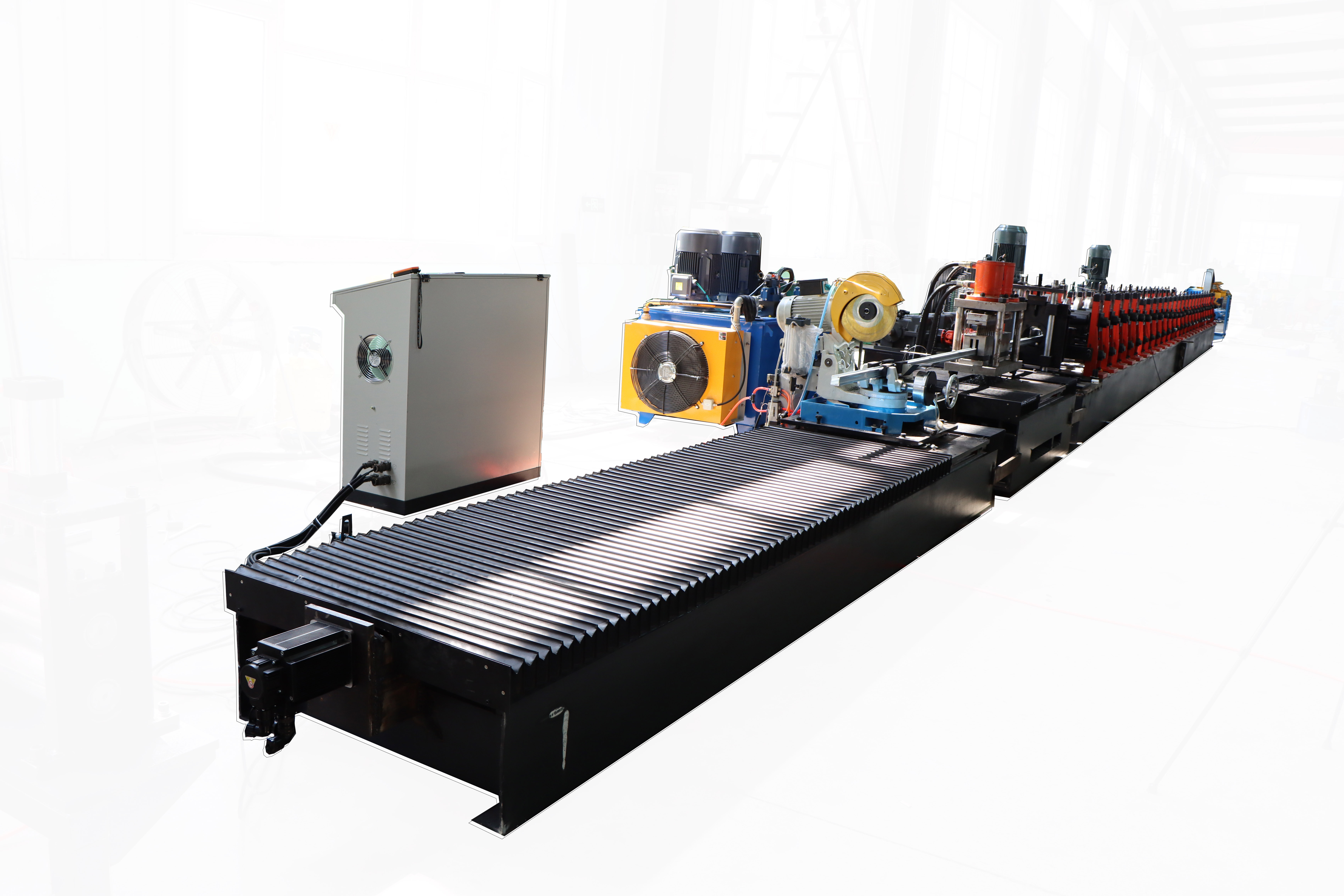

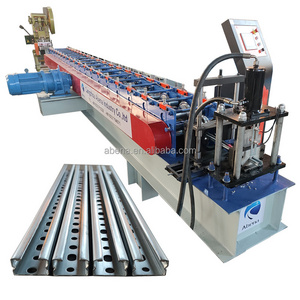

HUAYANG SOLAR STRUT C CHANNEL ROLL FORMING MACHINE

Full automatic solar strut channel roll forming machine

is the whole production line is under

GB/T6725-2002《

Technical conditions for cold formed steel sections

》GB6723-86《

Dimensions, shape, weight, and allowable deviations of general cold formed open section steel

》 standard ,which can produce all sizes solar strut ,such as 41*21/41*41/41*52/41*62/41*72,the

advanced

servo cutting system g

reatly increased production speed and saved costs.the speed can get 25m/min

solar strut channel

Simple construction, strong stability, and more shockproof tooth design.

Based on its long-term outdoor use, it must be able to withstand wind loads and other external effects.

Product Details

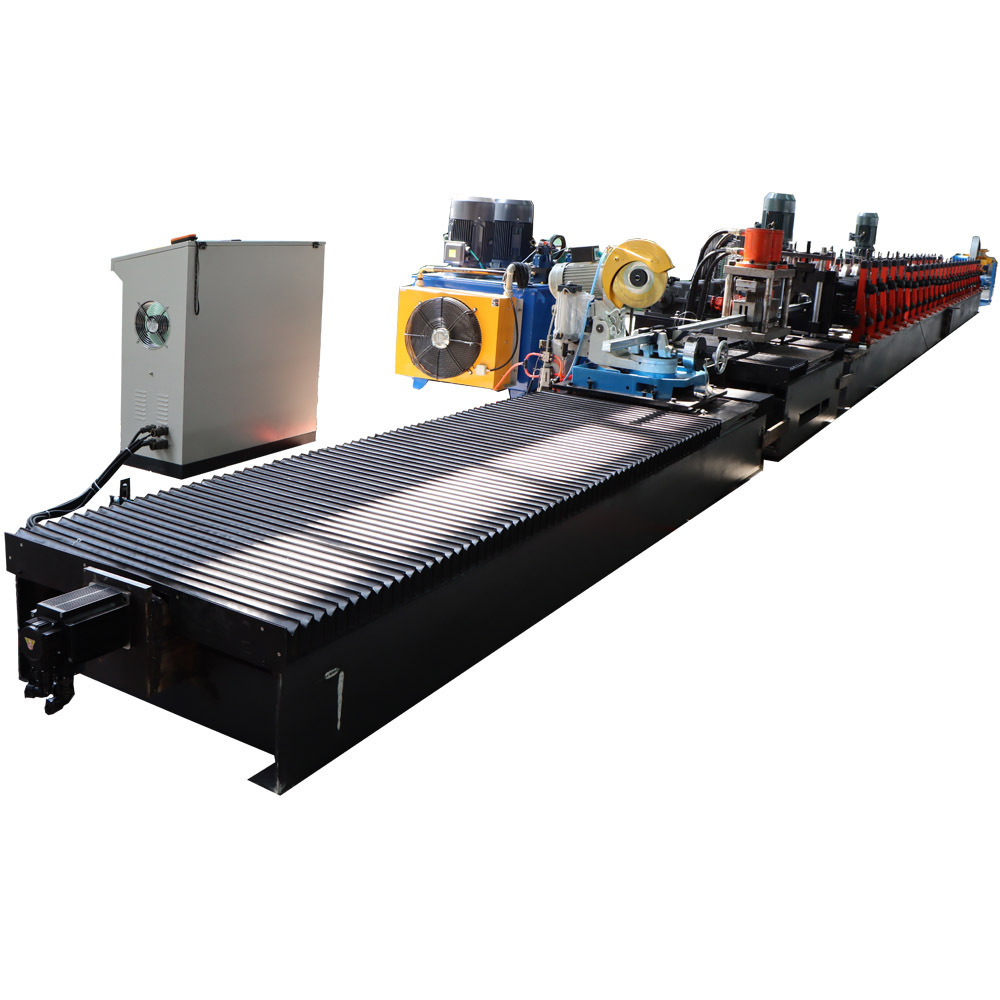

The whole

solar strut channel production line

including the decoiler -feeding and leveling device-roll forming machine -straightening device-servo punching device-servo cutting device -automatic table ,which is automatic controlled by the PLC.the servo cutting and servo punching power is from the hydraulic station .

|

Leveling and Feeding device

|

Steel plate welded as the feeding platform

|

|

|

|

7-roller leveling (up 3 down 4)

|

|

|

|

Equipped 2-3 stripes in the middle of the platform to feed material,

prevent the material surface damaged

|

|

|

|

There are several bearing besides the platform, to protect

the edge of the material

|

|

|

|

There are guide positioning wheels at the feeding and discharging ports of the leveling device

|

|

|

Rolling shaft

|

Shaft material:45# STEEL

|

|

|

|

Shaft diameter: 80 mm

|

|

|

|

Cr12 die steel vacuum quenched hardness HRC58~62 degrees

|

|

|

Roller

|

45# steel

|

|

|

|

0.03mm Chromed treatment, make the rollers more smoothly, improve the hardness and prevent abrasion, anti corrosion increase of

service life |

|

|

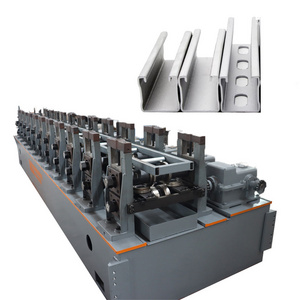

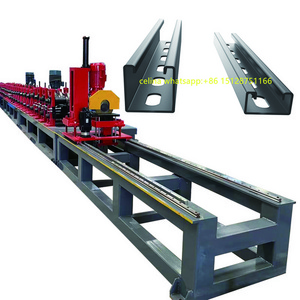

Rolling station

|

23 rolling stations with Universal straightening device

|

|

|

Work speed

|

25m/min

|

|

|

Machine basic frame

|

archway structure- QT640+570 castings

|

|

|

|

the sliders are castings (HT200) annealed and CNC finished

|

|

|

Work power

|

Two sets 15KW K series hard-tooth reducers total 30KW

|

|

|

Rolling spacer

|

Anti rusty treatment

|

|

|

Transmission

|

170 gear box transmission, universal joint connection.

|

|

|

more details please send inquiry to know more

|

|

|

Feeding device

The guide device is composed of a bracket, a side guide roller and an adjusting device. The position of the side guide roller can be adjusted horizontally by the left and right screw rods to ensure the accurate and stable introduction of the sheet material and prevent the profile from running off during the forming process.

leveling device

Steel plate welded as the feeding platform

7-roller leveling (up 3 down 4)Equipped 2-3 stripes in the middle of the platform to feed material, prevent the material surface damagedThere are several bearing besides the platform, to protect the edge of the material

There are guide positioning wheels at the feeding and discharging ports of the leveling device

roll forming machine

The roller adopts combined structure to reduce the speed difference and forming resistance, and has little wear on the surface of steel plate; The roller is processed by numerical control after Cr12 overall quenching, and the hardness can reach HRC58-62; It has the characteristics of high strength, high hardness, high precision and long service life.

straighten device

The straightening device consists of a base, a horizontal adjustment seat, a vertical adjustment screw, a column, a horizontal base, a rotary table, etc. This device can achieve horizontal lateral movement, vertical lifting, and rotation around the center adjustment, in order to achieve the correction requirements for lateral bending, up and down bending, and torsion of the workpiece.

punching device

A set of servo punching devices that are not commonly used, using DC53 imported cold work die steel material. It saves labor, saves space and is fast. It is our company's patented technology and is currently the most advanced earthquake-resistant photovoltaic punching system in the country.

track cutting system

The servo cutting device is placed behind the molding machine and adopts the punching and cutting mode. The servo motor drives the tracking system. The length of the product is set by measuring the length with a counter or the length of the product is located by measuring the hole with a photoelectric switch. When the set length is reached, the hydraulic machine moves to cut off the profile. , the tracking system returns to its original position.

auto receiving table

It can automatically move up and down through pneumatic force to automatically receive the solar strut channels

Certificate

COMPANY PROFILE

Customer Visit

Engineer Debugging

Package and Delivery

Hot Searches