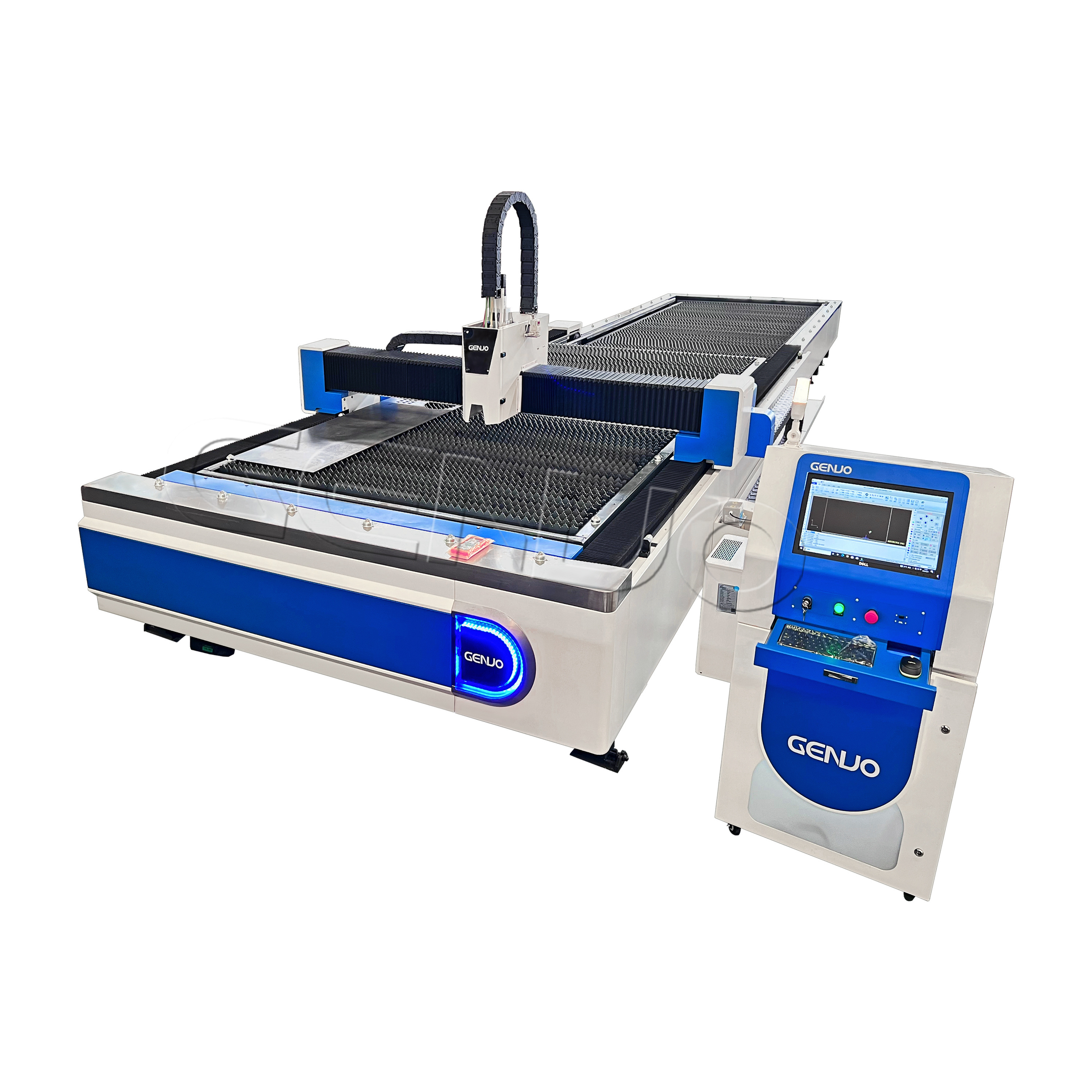

of the crossbeam ensure the high-speed move-ment during laser processing. At the same time, it has perfect dynamic perfor-mance and meets the accuracy. With long servicelife, it can keep the shape unchang

-ed

to the great

est extent, so as to ensure

the cutting accuracy and product quality.