- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V 3PH

-

Power:

-

5.5kw

-

Dimension(L*W*H):

-

2.8*1.8*1.95m

-

Weight:

-

1000 kg

-

Product name:

-

Automatic paper tube making machine toilet paper core curling machine

-

Finished Products:

-

Paper tube

-

Raw material:

-

bobbin paper

-

Application:

-

Paper tube making machine

-

Function:

-

Paper Tube Forming

-

Speed:

-

3-20m/min

-

Color:

-

Customized Color

-

Automation:

-

Semi Atuomatic/Full Atuomatic

-

Certification:

-

CE.ISO

-

Key words:

-

Roll Paper Tube Making Machine

Quick Details

-

Production Capacity:

-

3-20m/min

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Young Bamboo

-

Voltage:

-

380V 3PH

-

Power:

-

5.5kw

-

Dimension(L*W*H):

-

2.8*1.8*1.95m

-

Weight:

-

1000 kg

-

Product name:

-

Automatic paper tube making machine toilet paper core curling machine

-

Finished Products:

-

Paper tube

-

Raw material:

-

bobbin paper

-

Application:

-

Paper tube making machine

-

Function:

-

Paper Tube Forming

-

Speed:

-

3-20m/min

-

Color:

-

Customized Color

-

Automation:

-

Semi Atuomatic/Full Atuomatic

-

Certification:

-

CE.ISO

-

Key words:

-

Roll Paper Tube Making Machine

Products Description

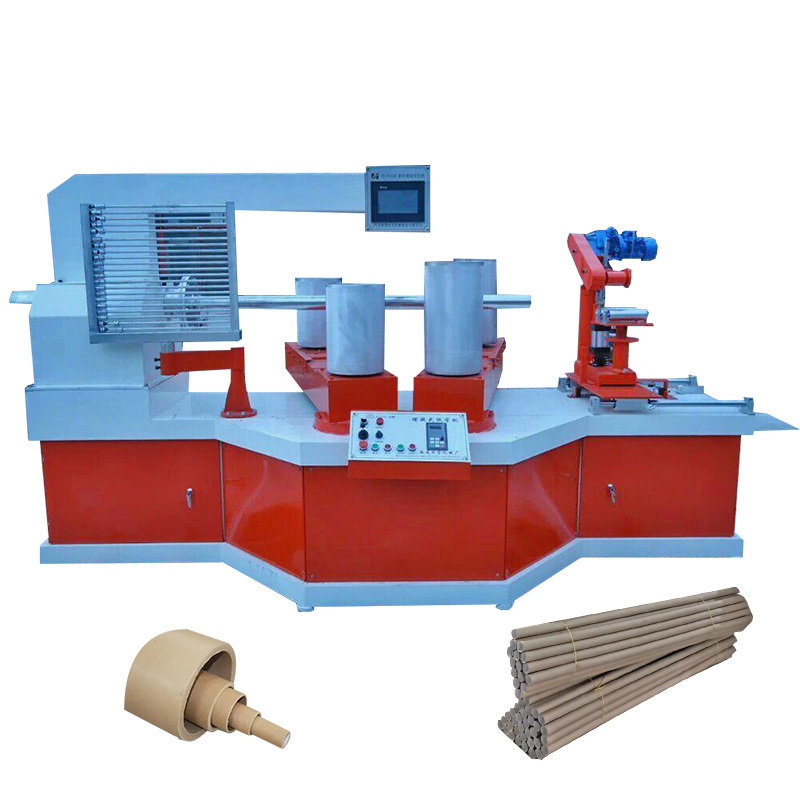

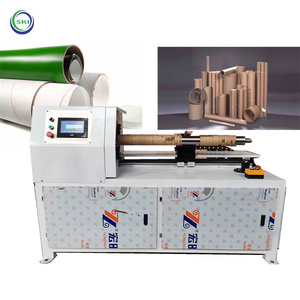

Automatic parallel paper tube making machine toilet paper core curling machine

Paper core machine is mainly used for making paper tube. The tubes made can be used as core of toilet paper roll. We have different model of paper core machine for choice, can make paper tube with different diameter and thickness.The finished tube can be cut and discharged automatically. Infrared and automatic transmission make cutting length more accurate.

Product Paramenters

|

Machine Type

|

FY-2150A

|

FY-2150B

|

FY-4150A

|

FY-4150B

|

|||

|

Tube Layer

|

3-10 ply

|

3-16 ply

|

3-21 ply

|

3-24 ply

|

|||

|

Tube Diameter

|

20-100mm

|

20-150mm

|

40-200mm

|

40-250mm

|

|||

|

Tube Thickness

|

1-6mm

|

1-8mm

|

1-20mm

|

1-20mm

|

|||

|

Working Speed

|

3-15m/min

|

3-20m/min

|

3-15m/min

|

3-20m/min

|

|||

|

Power

|

4KW

|

5.5KW

|

11KW

|

11KW

|

|||

|

Host Size

|

2.9*1.8*1.7m

|

2.9*1.9*1.7m

|

4.0*2.0*1.95m

|

4.0*2.0*1.95m

|

|||

|

Total Weight

|

1800kg

|

1800kg

|

3200kg

|

3500kg

|

|||

|

Belt Diagonal

|

Manual

|

Electric

|

Electric

|

Electric

|

|||

|

Winding Head

|

Two winding heads single belt

|

|

Four winding heads double belt

|

|

|||

|

Voltage

|

380V, 50Hz or 220V, 50Hz

|

|

|

|

|||

Application

Features of High Speed Automatic Spiral Cardboard Paper Tube Core Making Machine

1. The mainframe adopts heavy steel plate welded after CNC cutting, the machine is stable and not easy to deform

2.The main machine adopts hard tooth surface full oil bath chain transmission, low noise.

3.The mainframe adopts vector type High torque inverter speed regulation

4.PLC control system is used to improve cutting response speed, cutting length control is more accurate than ever.

5.With multi-function bottom paper supply device, paper breaking automatic paper stop function.

1. The mainframe adopts heavy steel plate welded after CNC cutting, the machine is stable and not easy to deform

2.The main machine adopts hard tooth surface full oil bath chain transmission, low noise.

3.The mainframe adopts vector type High torque inverter speed regulation

4.PLC control system is used to improve cutting response speed, cutting length control is more accurate than ever.

5.With multi-function bottom paper supply device, paper breaking automatic paper stop function.

Related Products

Hot Searches