- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

HAOSEN

-

Model Number:

-

HSSZN-650

-

Voltage:

-

380V,50HZ,3P ,4 L,AC

-

Dimension(L*W*H):

-

19 m*2.2 m*2.1m

-

Weight:

-

14000 KG

-

Marketing Type:

-

Other

-

Max Speed:

-

80-120 pcs/min

-

Max layers:

-

4(1-4 layers supported)

-

Operators:

-

1- 2

-

Inner layer Material:

-

Kraft Paper, PE film, Metal Foil Paper

-

Kraft paper gram weight:

-

75-120 gsm

-

Max diameter of paper reel:

-

1200mm

-

Max paper width:

-

1250mm

-

Paper reel inner core diameter:

-

76mm

-

Cutting bags counting:

-

Automatic photoelectric counting

-

In line printer:

-

Flexo Stagger Printer

-

Max Printing colors:

-

4(1-4 colors supported)

Quick Details

-

Machine Type:

-

Bag Forming Machine

-

Bag Type:

-

Other

-

Material:

-

Plastic

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

HAOSEN

-

Model Number:

-

HSSZN-650

-

Voltage:

-

380V,50HZ,3P ,4 L,AC

-

Dimension(L*W*H):

-

19 m*2.2 m*2.1m

-

Weight:

-

14000 KG

-

Marketing Type:

-

Other

-

Max Speed:

-

80-120 pcs/min

-

Max layers:

-

4(1-4 layers supported)

-

Operators:

-

1- 2

-

Inner layer Material:

-

Kraft Paper, PE film, Metal Foil Paper

-

Kraft paper gram weight:

-

75-120 gsm

-

Max diameter of paper reel:

-

1200mm

-

Max paper width:

-

1250mm

-

Paper reel inner core diameter:

-

76mm

-

Cutting bags counting:

-

Automatic photoelectric counting

-

In line printer:

-

Flexo Stagger Printer

-

Max Printing colors:

-

4(1-4 colors supported)

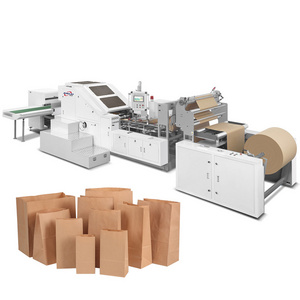

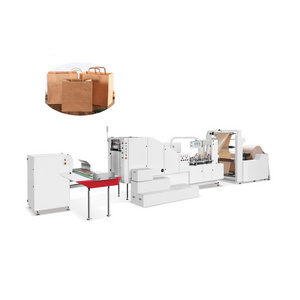

Products Description

|

Model of machine

|

HSSZN-650

|

Speed of bag making

|

80-120 pcs/min

|

|

Finished bag width

|

380-630mm, free adjustment (Customized in bag size range)

|

Bag side

|

Straight or folding side (“M” side gusset width size: 0-140mm)

|

|

Bag length

|

Free adjusted,

PLC servo control the cutting length. Touch screen freely set the length |

Machine Dimensions

|

Length15m×Width2.4 m× Height 2.1m

|

|

Max layers

|

4(1-4 layers supported)

|

Max Printing colors

|

4(1-4 colors supported)

|

Brief Introduction

The tuber machine is with light, electricity, gas three-in-one high automatic production technology. It has the characteristics like human-computer interface adjustment (Touch screen control), Frequency control, Precision Servo, PLC programming control systems, Automatic counting, Alarming system for security production etc.

Bag Tubes Making Process

Feature

1.The machine adopts dc motor to maintain stable operation in acceleration

(frequency speed adjustment is also available)

2.Automatic meters counting and alarming system

3.Rewinding adopts A air shaft structure, easy to load and unload

4.The unwinding adopts photoelectric web guiding system, so that irregularly shaped material can be normally cut.

5. Flat knife longitudinal cutting waste edge automatic discharge device

Certifications

Hot Searches