- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

2ml

-

Voltage:

-

1PH 220v 50/60Hz

-

Place of Origin:

-

Shanghai

-

Brand Name:

-

Weibang

-

Dimension(L*W*H):

-

2400x1600x1700mm

-

Weight:

-

650 KG

-

Product name:

-

Energy Drink Filling Machine

-

Filling nozzles:

-

6

-

adding plug /dropper nozzle:

-

1

-

Tighten nozzle:

-

1

-

Filling range:

-

50-1000ml

-

Capacity:

-

10-35 bottles/min

-

Filling ACCURACY:

-

1%

-

Power:

-

1.5KW

-

NET Weight:

-

650kgs

Quick Details

-

Machinery Capacity:

-

1000BPH

-

Packaging Material:

-

Wood, bottle filling line

-

Filling Material:

-

Milk, Oil, Juice, hand soap, hand sanitizer gel, syrup, Energy shot drinks

-

Filling Accuracy:

-

2ml

-

Voltage:

-

1PH 220v 50/60Hz

-

Place of Origin:

-

Shanghai

-

Brand Name:

-

Weibang

-

Dimension(L*W*H):

-

2400x1600x1700mm

-

Weight:

-

650 KG

-

Product name:

-

Energy Drink Filling Machine

-

Filling nozzles:

-

6

-

adding plug /dropper nozzle:

-

1

-

Tighten nozzle:

-

1

-

Filling range:

-

50-1000ml

-

Capacity:

-

10-35 bottles/min

-

Filling ACCURACY:

-

1%

-

Power:

-

1.5KW

-

NET Weight:

-

650kgs

Sample

Details Images

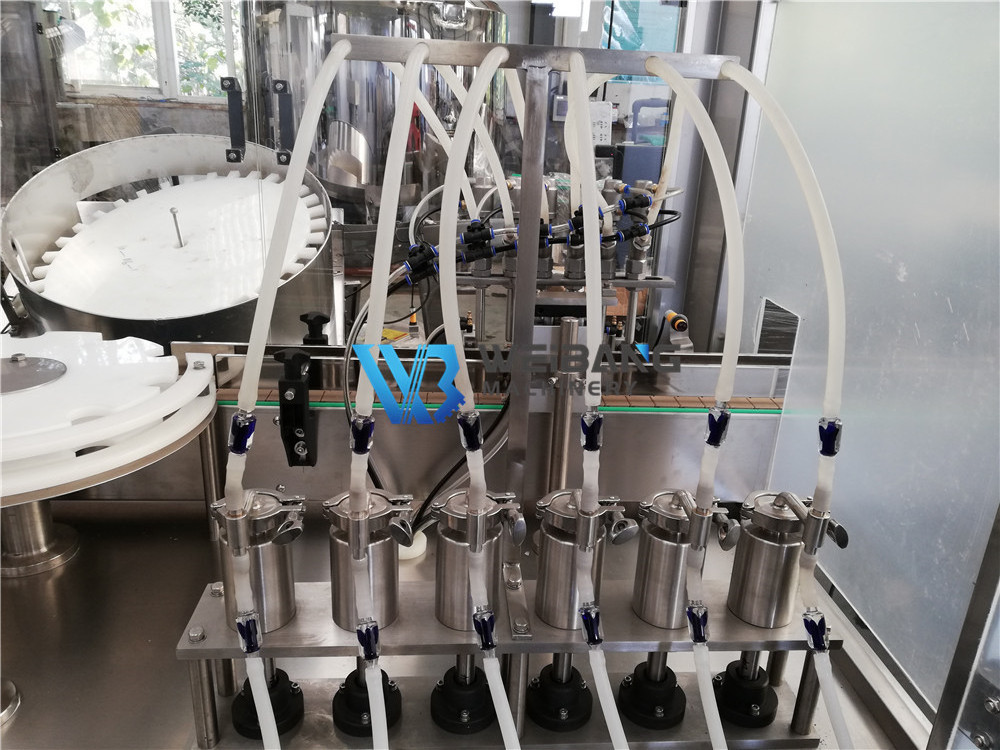

Automatic bottling equipment 100ml 250ml syrup beverages vinegar Energy Drink Filling Machine

---

Model no.YG6

Automatic filling capping labeling line

Automatic filling capping labeling line

Can customized as 4/6/8 filling nozzle according to your production capacity

can customized the machine with a semi-feeder plate , and collect plate

6 filling ,1 add cover ,1 tighten capper

Title goes here.

Servo motor control ,easy operation

Highly precised piston pump

Piston pump filling nozzle

8 head filling (filling nozzle can be customized to 4 /6/10/12)

304/316 Stainless steel high precision filling nozzle.

Filling volume adjustable in fine rank, same liquid level after filling.

All 304/316 stainless steel contact parts & liquid tank, fine polish, no death corner, easy to clean.

304/316 stainless steel filling pump

8 head filling (filling nozzle can be customized to 4 /6/10/12)

304/316 Stainless steel high precision filling nozzle.

Filling volume adjustable in fine rank, same liquid level after filling.

All 304/316 stainless steel contact parts & liquid tank, fine polish, no death corner, easy to clean.

304/316 stainless steel filling pump

The piston size and volume determine a piston filling machine's filling range.

Spray /dispenser pump/flip top lid feeder ,vibrate bowl system

Place and capping system, tighten with 2 plastic rubber

No bottle no capping

No bottle no capping

Related machines

WB- GP800,SEMI-Automatic bottle feeder

BOTTLE UNSCRAMBLER FOR glass bottles

Mixing tank

Capacity from 100L to 2000L

PRODUCT SPECIFICATIONS

Application :

This filling machine suitable for filling and capping semi-liquid products without or with small particles: such as sweet chili sauce,beef paste, bean sauce, mushroom sauce, tomato sauce, peanut butter, jam, honey, sauce, shrimp paste, shampoo, body wash, liquid detergent, dish washing liquid, etc.

This filling machine suitable for filling and capping semi-liquid products without or with small particles: such as sweet chili sauce,beef paste, bean sauce, mushroom sauce, tomato sauce, peanut butter, jam, honey, sauce, shrimp paste, shampoo, body wash, liquid detergent, dish washing liquid, etc.

Performance feature:

1. Adopts plunger type metering pump filling, high precision; The structure of pump adopts fast disassembly institutions, easy to

clean and disinfect.

2. PLC control system , color touch screen display.

3. This machine has function of no bottle no filling and automatic counting.

4. The filling nozzle was equipped with drip-proof device .

5. W hen filling liquid, the filling nozzle dive into the bottom of bottle, rising slowly , it can effectively prevent bubbles.

6. Machine body and the parts contact ing liquid are made of stainless steel, full compliance with GMP standard

1. Adopts plunger type metering pump filling, high precision; The structure of pump adopts fast disassembly institutions, easy to

clean and disinfect.

2. PLC control system , color touch screen display.

3. This machine has function of no bottle no filling and automatic counting.

4. The filling nozzle was equipped with drip-proof device .

5. W hen filling liquid, the filling nozzle dive into the bottom of bottle, rising slowly , it can effectively prevent bubbles.

6. Machine body and the parts contact ing liquid are made of stainless steel, full compliance with GMP standard

|

Model

|

WB-YG4

|

WB-YG6

|

WB-YG8

|

|

Filling head number

|

4

|

6

|

8

|

|

Add plug /dropper head

|

1

|

1

|

1

|

|

Capping head number

|

1

|

1

|

2

|

|

Filling volume

|

50-1000ml

|

50-1000ml

|

50-1000ml

|

|

Capacity

|

5-25bottles/min

|

10-35bottles/min

|

20-50bottles/min

|

|

Filling accuracy

|

≤ ±1%

|

≤ ±1%

|

≤ ±1%

|

|

Pass rate

|

≥ 98%

|

≥ 98%

|

≥ 98%

|

|

Power supply

|

1ph 220V, 50/60Hz

|

1ph 220V, 50/60Hz

|

1ph 220V, 50/60Hz

|

|

Power

|

1.5 KW

|

1.7 KW

|

2.1 KW

|

|

Net weight

|

450kg

|

600kg

|

700kg

|

|

Overall dimension

|

L2200 × W2000 × H1750mm

|

L2400 × W2000 × H1750mm

|

L2600 × W2000 × H1750mm

|

Contact

Company introduction

Certifications

FAQ

1: Q:Are you a factory or trading company ?

A: We are a professional manufacturer of Vertical packing machine,horizontal packing and bottle filling machines . At the same time , we are also a trustworthy supplier of other packing equipment ,including tea bag packing machine , wet wipes fold and packing machine , yogurt cup filling and sealing machine , Labeling machine, shrink sleeve labeling machine , box cartooning machine , metal detector, inkjet printing machine , mixing tank and hard candy packing machine and so on .

2, Q: Trade assurance order is OK?

A: Sure ,we are happy to conclude trade assurance order, which warranty you quality, on time delivery and payment protection.

3, Q: What is the MOQ ?

A: 1 set .

4, Q: How long is the lead time ?

A : All machine takes around 10-25 days after deposit payment .

5, Q: What is your warranty and after-sale service

A: One year warranty and Lifelong after-sale service via skype/whatsapp/mobile/etc .Also Technical service is available.

6,Q:Can I Visit factory and send team for Learning and inspect?

A:Yes, sure, Welcome your visit and no problem for your team come and learning, we will do our best to teaching they how to use the machine .

7, Q: Which is the nearest sea port for you ?

A : Our company located at Shanghai city ,so Shanghai Port is the nearest port for us . But we can delivery the goods to any port as your request .

8, Q: What advantages we have?

A: Rich experience: We have over 15 years experience in exporting packing machine and bottle filling line , all of our sales have been in packing and filling industry over 8 years , some over 15 years . We have our own experienced engineers in R&D , we keep improving the products quality level , design new and economic products to meet our customers’ different requirement . We have our own factory , so that , no matter the packing machine and filling machines which manufactured by ourselves , but also other related machine we get from our partners . All will be re-tested again in our factory .

A: We are a professional manufacturer of Vertical packing machine,horizontal packing and bottle filling machines . At the same time , we are also a trustworthy supplier of other packing equipment ,including tea bag packing machine , wet wipes fold and packing machine , yogurt cup filling and sealing machine , Labeling machine, shrink sleeve labeling machine , box cartooning machine , metal detector, inkjet printing machine , mixing tank and hard candy packing machine and so on .

2, Q: Trade assurance order is OK?

A: Sure ,we are happy to conclude trade assurance order, which warranty you quality, on time delivery and payment protection.

3, Q: What is the MOQ ?

A: 1 set .

4, Q: How long is the lead time ?

A : All machine takes around 10-25 days after deposit payment .

5, Q: What is your warranty and after-sale service

A: One year warranty and Lifelong after-sale service via skype/whatsapp/mobile/etc .Also Technical service is available.

6,Q:Can I Visit factory and send team for Learning and inspect?

A:Yes, sure, Welcome your visit and no problem for your team come and learning, we will do our best to teaching they how to use the machine .

7, Q: Which is the nearest sea port for you ?

A : Our company located at Shanghai city ,so Shanghai Port is the nearest port for us . But we can delivery the goods to any port as your request .

8, Q: What advantages we have?

A: Rich experience: We have over 15 years experience in exporting packing machine and bottle filling line , all of our sales have been in packing and filling industry over 8 years , some over 15 years . We have our own experienced engineers in R&D , we keep improving the products quality level , design new and economic products to meet our customers’ different requirement . We have our own factory , so that , no matter the packing machine and filling machines which manufactured by ourselves , but also other related machine we get from our partners . All will be re-tested again in our factory .

Hot Searches