> Payment Terms:

60/90 Days

with quality assurance.

Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

cnc aluminum parts--A12

-

Brand Name:

-

WINNER

-

Product name:

-

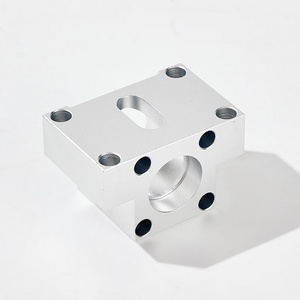

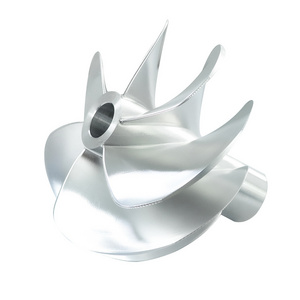

metal stainless steel aluminum 5 axis cnc machining parts for cnc

-

Material:

-

Stainless steel,Brass,Copper,Aluminum alloy,Aluminum,Zinc

-

Machining type:

-

CNC Milling Machining parts

-

Shank size:

-

cnc metal parts

-

Keyword:

-

CNC Macining Parts

-

Packing:

-

Customized according to customer needs

-

Model:

-

CNC Lathe/Milling machining/Automobile

-

Name:

-

supplier oem parts fabrication service cnc

-

Process:

-

Cnc Machining+deburrs

-

Service:

-

Customized OEM CNC Machining

Quick Details

-

CNC Machining or Not:

-

Cnc Machining

-

Material Capabilities:

-

Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless steel, Steel Alloys, cnc machining parts

-

Place of Origin:

-

Guangdong, China

-

Model Number:

-

cnc aluminum parts--A12

-

Brand Name:

-

WINNER

-

Product name:

-

metal stainless steel aluminum 5 axis cnc machining parts for cnc

-

Material:

-

Stainless steel,Brass,Copper,Aluminum alloy,Aluminum,Zinc

-

Machining type:

-

CNC Milling Machining parts

-

Shank size:

-

cnc metal parts

-

Keyword:

-

CNC Macining Parts

-

Packing:

-

Customized according to customer needs

-

Model:

-

CNC Lathe/Milling machining/Automobile

-

Name:

-

supplier oem parts fabrication service cnc

-

Process:

-

Cnc Machining+deburrs

-

Service:

-

Customized OEM CNC Machining

Products Display

|

Business Type

|

Factory / Manufacturer

|

|

Service

|

CNC Machining

|

|

|

Turning and Milling

|

|

|

CNC Turning

|

|

|

OEM Parts

|

|

Material

|

1). Aluminum: AL 6061-T6, 6063, 7075-T etc

|

|

|

2). Stainless steel: 303,304,316L, 17-4(SUS630) etc

|

|

|

3). Steel: 4140, Q235, Q345B,20#,45# etc.

|

|

|

4). Titanium: TA1,TA2/GR2, TA4/GR5, TC4, TC18 etc

|

|

|

5). Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc

|

|

|

6). Copper, bronze, Magnesium alloy, Delrin, POM,Acrylic, PC, etc.

|

|

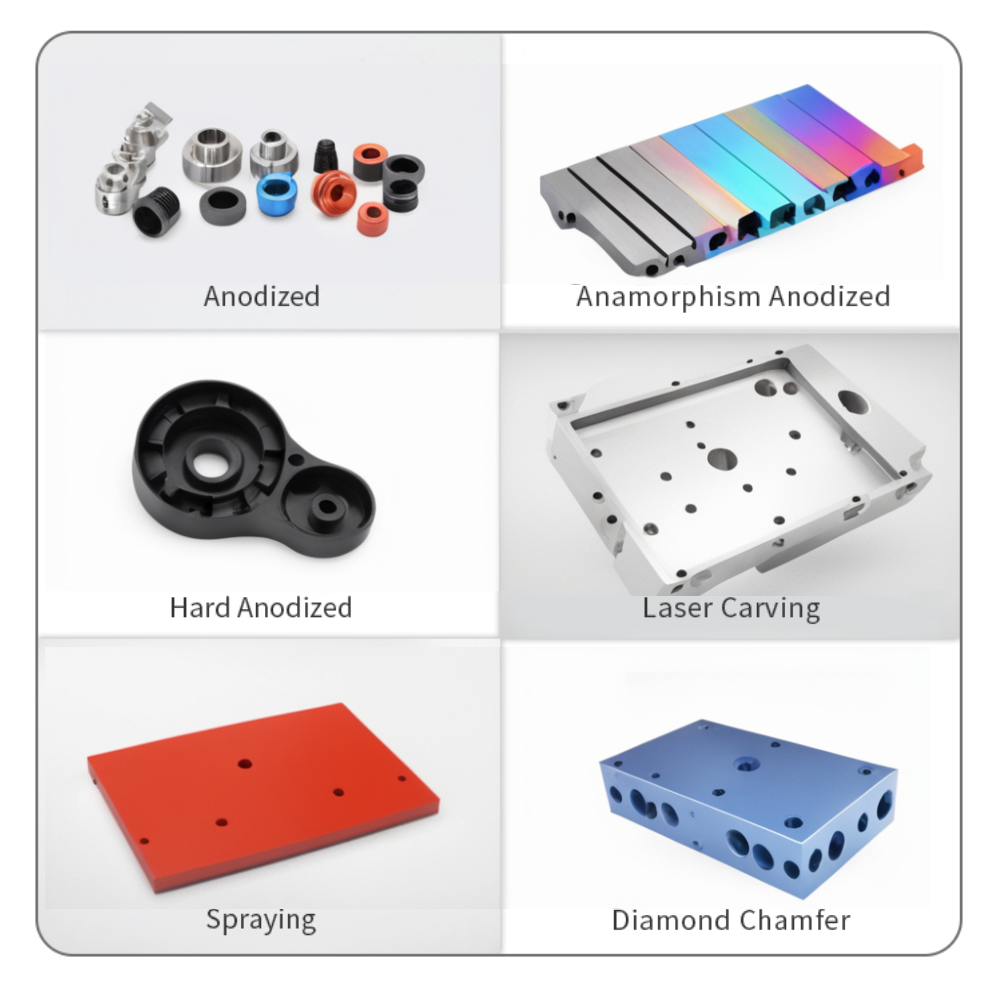

Finish

|

Sandblasting, Anodize color, Blackenning, Zinc/Nickl Plating, Polish,

|

|

|

Power coating, Passivation PVD, Titanium Plating, Electrogalvanizing,

|

|

|

electroplating chromium, electrophoresis, QPQ(Quench-Polish-Quench),

|

|

|

Electro Polishing,Chrome Plating, Knurl, Laser etch Logo, etc.

|

|

Main Equipment

|

CNC Machining center(Milling), CNC Lathe, Grinding machine,

|

|

|

Cylindrical grinder machine, Drilling machine, Laser Cutting Machine,etc.

|

|

Drawing format

|

STEP,STP,GIS,CAD,PDF,DWG,DXF etc or samples.

|

|

Tolerance

|

+/-0.01mm ~ +/-0.05mm

|

|

Surface roughness

|

Ra 0.1~3.2

|

|

Inspection

|

Complete inspection lab with Micrometer, Optical Comparator, Caliper Vernier,CMM

|

|

|

Depth Caliper Vernier, Universal Protractor, Clock Gauge, Internal Centigrade Gauge

|

|

Capacity

|

CNC turning work range: φ0.5mm-φ150mm*300mm

|

|

|

CNC milling work range: 510mm*1020mm*500mm

|

Product Details

>

Instant CNC online quotes

> Free sample & Automatic DFM feedback

> Tolerances down to

±0.0004″ (0.01mm)

> Machined parts as fast as 1 day

Recommend Products

Our Factory

High Precision cnc Machining Parts

12 +

Years CNC Machining

> Supply Ability: 300000 Product per month

> Machinery Axis: 3,4,5,6

> Tolerance: 0.01~0.005 mm

> Machined parts as fast as 1 day

> Payment Terms:

60/90 Days

with quality assurance.

> 1200+ Product Series with standard parts and ODM/OEM SERVICES

> 1200+ Product Series with standard parts and ODM/OEM SERVICES

> All products WITH

FULLY INSPECTION

We are engaged in precision mould,

CNC turning parts, CNC milling parts and cnc machining parts.

Our products are mainly used for industrial equipments and medical equipments. We can make products with material of stainless steel, steel alloy, copper, aluminum, pom ,peek, bronze alloy,nylon, derlin, PTFE etc. The surface treatment we can handle is anodize, black oxide, powder coating, high polishing and plating.

In order to make sure the critical dimensions, we import our machines from USA and Japan. The minimum tolerance we can make is

0.005-0.01 millimetre. Our engineers are quite experienced and can supply OEM/ODM service or will offer some advices when you need. Our

works are trained and follow ISO standard. Choose WINNER AS YOUR LONGTERM GOLDEN SUPPLIER, we will exceed your expectation. So if anything we can help or any more information you need, please feeling free to contact us.

In order to make sure the critical dimensions, we import our machines from USA and Japan. The minimum tolerance we can make is

0.005-0.01 millimetre. Our engineers are quite experienced and can supply OEM/ODM service or will offer some advices when you need. Our

works are trained and follow ISO standard. Choose WINNER AS YOUR LONGTERM GOLDEN SUPPLIER, we will exceed your expectation. So if anything we can help or any more information you need, please feeling free to contact us.

Cnc Machining Centers

Production Workshop

CNC Turning/milling

2-Dimensional Measuring Instrument

CMM

Your Exclusive Customer Service

Our Service

we can customize aluminum alloy ,stainless steel ,aluminum -alloy block ,brass, pom,copper ,tube material , sepecial steel,

Customer photo

At our machine shop, customer satisfaction speaks louder than words ever could. We pride ourselves on providing precisely machinedcomponents along with best-in-class service and support. Don't just take our word for it - read what our clients have to say.

"We can always count on their parts exceeding our rigorous tolerances. Their attention to detail and quality control is truly

impressive."

Very satisfied with the quality of the products. The products were manufactured precisely according to the specification. The finish and craftmanship is of very high quality, and the level of detail and machining tolerances are as expected. Dimensional tolerances of max. +-0,35% of specified 3D drawings. The supplier delivered on-time, if not earlier than promised. Super satisfied with the lead time and shipping handling. Overall I have received a very informed and professional service from this supplier. Warm recommendations from a Danish customer.

FAQ

1. Are you a manufacturer or a trading company?

We are a factory located in Dongguan, China, with 12+ years of rich experience,covering 4000 square meters. Complete facilities, including 3D quality inspection equipment, ERP system and 80 machines. If necessary, we can provide you with material certificates, sample quality inspection and

Video factory inspection.

2. How to get a quote?

Detailed drawings (PDF/STEP/IGS/DWG...), including quality, delivery date, materials, quality, quantity, surface treatment and

other information.

3. Can your engineering team draw for my creativity?

2. How to get a quote?

Detailed drawings (PDF/STEP/IGS/DWG...), including quality, delivery date, materials, quality, quantity, surface treatment and

other information.

3. Can your engineering team draw for my creativity?

Of course, we are also glad to receive your samples, pictures or detailed size

drafts for accurate quotation.

4. Can you provide samples before mass production?

Of course, the sample fee is necessary. If possible, it will be returned during mass production.

5. What is the delivery date?

Generally, the sample lasts for 1-2 weeks and the batch production lasts for 3-4 weeks.

6. How do you control quality?

(1) Material Inspection - Check material surfaces and approximate dimensions.

(2) First inspection of production - ensure

critical dimensions in mass production.

(3) Sampling inspection - check the quality before delivery to the warehouse.

(4) Preshipment inspection - 100% inspection by QC assistant before shipment.

7. After sales service team

If you have any problems after receiving the product, you can provide feedback through voice call, video conference, email, etc.

within one month. Our team will provide you with solutions within a week.

drafts for accurate quotation.

4. Can you provide samples before mass production?

Of course, the sample fee is necessary. If possible, it will be returned during mass production.

5. What is the delivery date?

Generally, the sample lasts for 1-2 weeks and the batch production lasts for 3-4 weeks.

6. How do you control quality?

(1) Material Inspection - Check material surfaces and approximate dimensions.

(2) First inspection of production - ensure

critical dimensions in mass production.

(3) Sampling inspection - check the quality before delivery to the warehouse.

(4) Preshipment inspection - 100% inspection by QC assistant before shipment.

7. After sales service team

If you have any problems after receiving the product, you can provide feedback through voice call, video conference, email, etc.

within one month. Our team will provide you with solutions within a week.

Hot Searches