- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

Design for different country

-

Power:

-

13.6KW

-

Dimension(L*W*H):

-

11.56*1.49*2.3m

-

Weight (KG):

-

2800

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Capacity:

-

80-200kg/h water evaporation

-

Heating source:

-

Steam, electricity, oil

-

Installation:

-

Engineer's Guidance

-

Advantage:

-

Low Consumption High Efficiency

-

Name:

-

mesh belt dryer

-

Function:

-

Food Dehydration Dryer

-

Product name:

-

Hot Air Drying Machine

Quick Details

-

Type:

-

Dry Cabinet

-

Place of Origin:

-

Liaoning, China

-

Brand Name:

-

WANDA

-

Voltage:

-

Design for different country

-

Power:

-

13.6KW

-

Dimension(L*W*H):

-

11.56*1.49*2.3m

-

Weight (KG):

-

2800

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Capacity:

-

80-200kg/h water evaporation

-

Heating source:

-

Steam, electricity, oil

-

Installation:

-

Engineer's Guidance

-

Advantage:

-

Low Consumption High Efficiency

-

Name:

-

mesh belt dryer

-

Function:

-

Food Dehydration Dryer

-

Product name:

-

Hot Air Drying Machine

Product Description

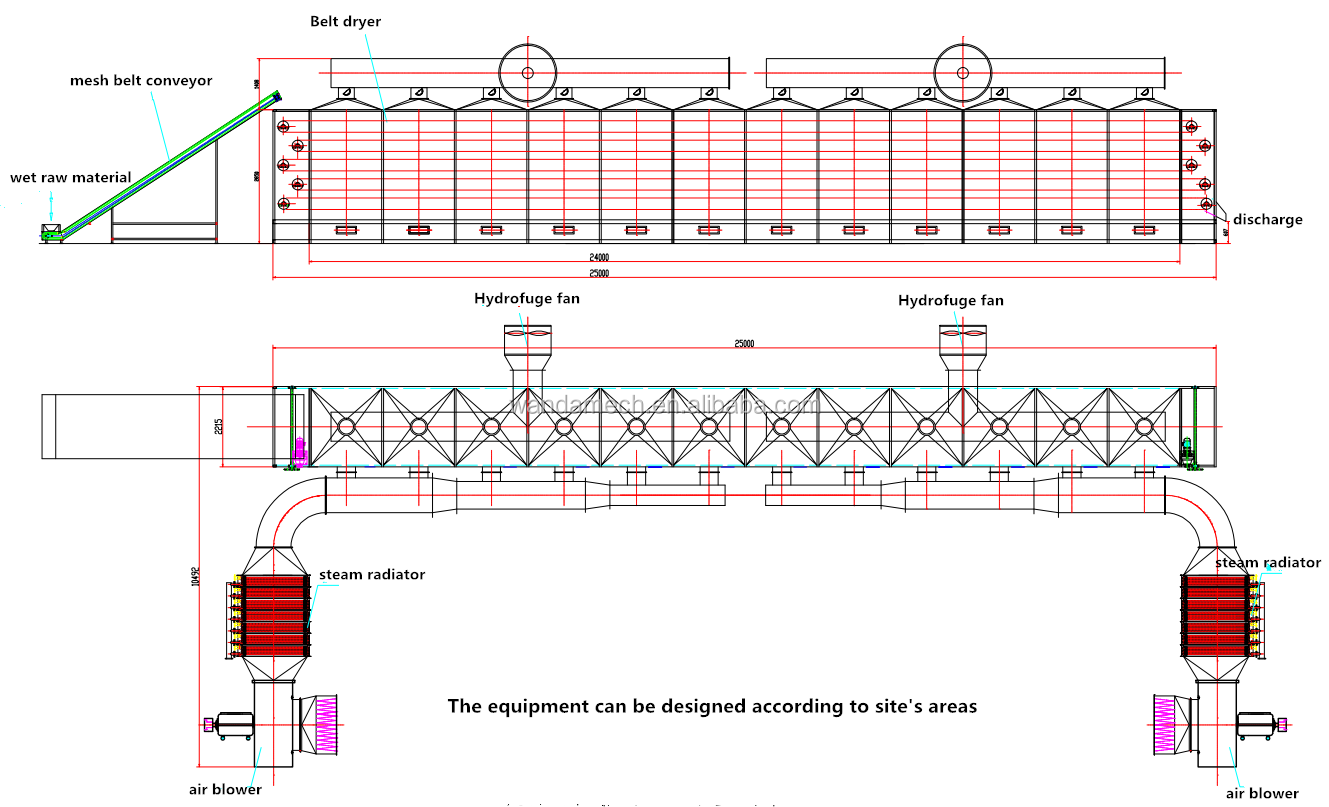

Belt dryer is a continuous drying equipment for batch production, which is used for drying flaky, strip and granular materials with good air permeability. It is especially suitable for dehydrated vegetables, catalysts, and other materials with high water content and high material temperature; This series of dryers have the advantages of fast drying speed, high evaporation intensity and good product quality. For the paste materials of dehydrated filter cake, they can only be dried after granulating or making into strips.

It has the advantages of high drying rate, high evaporation intensity and good product quality. Belt dryer is widely used in

industry, mainly for drying small pieces of materials and fibrous materials. In a word, the materials dried by the belt dryer must have a certain shape, and still keep a certain shape, and still keep a certain shape after drying.

Working Principle

The materials are uniformly distributed on the mesh belt by the material feeder. The mesh belt generally adopts 12-60 mesh stainless steel mesh and it is drawn by a transmission device and move inside the dryer . The dryer is composed of several sections. For each section, the hot air is circulated separately. Part of exhausted gas is exhausted by a special moisture exhaust blower. The waste gas is controlled by an adjustment valve. The hot air passes through the mesh-belt covered with bring water material away. The mesh-belt moves slowly, running speed can be freely adjusted according to the material property. The final products after the drying process will fall into the material collector continuously. The top and low circulation units can be freely equipped according to the user's requirements. The number of section might be selected according to the production demands.

Products Show

single layer belt dryer

multi layer belt dryer

Manufacture Site Display

Different types of mesh belt

Customer using site

Product Parameters

Product Features

(1) The vibration and impact of the material on the belt dryer are slight, and the material particles are not easy to pulverize

and break, so it is also suitable for drying some materials that are not allowed to break.

and break, so it is also suitable for drying some materials that are not allowed to break.

(2) The belt dryer is not only used for drying materials, but also for baking, firing or curing.

(3) The structure of the belt dryer is not complex, and it is easy to install. It can run for a long time. In case of failure, it can enter into the box for maintenance, which is convenient for maintenance.

(4) The air quantity, heating temperature, material residence time and feeding speed can be adjusted to achieve the

best drying effect.

best drying effect.

(5) The equipment configuration is flexible, and the mesh belt flushing system and material cooling system can be used.

(6) Most of the air is recycled and highly energy-saving.

(7) The unique air distribution device makes the hot air distribution more uniform and ensures the consistency of product quality.

(8) The heat source can be steam, heat transfer oil, electricity or coal (oil) stove.

Product Packaging

Our Company

LIAOYANG WANDA MACHINERY CO.,LTD

is specialized in design, development, manufacture and sale of industrial, chemical drying machines. Our Equipment includes spray dryer, fluid bed dryer, belt dryer, flash dryer, paddle dryer, rotary dryer, vacuum oven dryer, vacuum paddle dryer , hot air circulation oven dryer and so on.

Wanda Machinery not only has a group of capable engineers and senior management personnel with more than ten years of work experience, but also has a group of excellent production personnel. They have excellent capabilities in research, design, service, etc. Over the years, they have devoted themselves to researching and summing up in practice. "Pragmatism, innovation, integrity, pursuit of excellence", a deep understanding is a strong guarantee for the quality of customers' products!

Looking to the future with a commitment to design innovation and quality products, supported by an outstanding level of customer service. The excellent quality machinery can be easily obtained from us because we maintain the quality and standard of our products from incoming raw materials to the finished products.

Our Service

1. Introduce the product to the customer in detail, answer the question raised by customer carefully;

2. Make different plans for choice according to the needs and requirements of customers.

3. Help customers solve any other questions about products or other aspect;

4. We will provide one-year warranty period to make sure your machine runs consistently.

2. Make different plans for choice according to the needs and requirements of customers.

3. Help customers solve any other questions about products or other aspect;

4. We will provide one-year warranty period to make sure your machine runs consistently.

5.keep certain inventory level of spare parts, which means the replacements can be shipped to you right away.

6. Consultant services for whole machine life, 24 hours technical support by email and telephone.

7. Send technicians to the job site for guiding the installation and adjustment, training operators and finishing the check and accept together with you.

6. Consultant services for whole machine life, 24 hours technical support by email and telephone.

7. Send technicians to the job site for guiding the installation and adjustment, training operators and finishing the check and accept together with you.

8. Establish long-term and friendly relationship.

FAQ

1. What data is required to confirm the model?

(1) Materials to be dried (2) Treatment capacity per hour (3) Moisture requirements before and after drying (4)Heating

source(electricity/ gas/ thermal oil, etc)

2. What certificates do you have?

We can provide CE, ISO 9001, etc

3. What is the warranty period of the equipment?

Normally 1 year warranty

4. Can we visit your factory?

Sure, we sincerely invite you to visit

5. Can we bring our own materials to your factory for experiments?

Sure, you are welcome at any time. We will arrange professional engineers and technicians to do experiments and analyze data for you on site.

6. Can it be customized?

Sure, our equipment can be customized according to the actual requirements of customers.

7. How long is the construction period?

It's about 30 days, but it also needs to be determined according to the specific equipment model, order number, etc., But if you need it urgently, please let us know, we can arrange the factory to rush production.

8. Will you provide installation services?

If you need, we can arrange professional technicians and engineers to install and debug on site.

(1) Materials to be dried (2) Treatment capacity per hour (3) Moisture requirements before and after drying (4)Heating

source(electricity/ gas/ thermal oil, etc)

2. What certificates do you have?

We can provide CE, ISO 9001, etc

3. What is the warranty period of the equipment?

Normally 1 year warranty

4. Can we visit your factory?

Sure, we sincerely invite you to visit

5. Can we bring our own materials to your factory for experiments?

Sure, you are welcome at any time. We will arrange professional engineers and technicians to do experiments and analyze data for you on site.

6. Can it be customized?

Sure, our equipment can be customized according to the actual requirements of customers.

7. How long is the construction period?

It's about 30 days, but it also needs to be determined according to the specific equipment model, order number, etc., But if you need it urgently, please let us know, we can arrange the factory to rush production.

8. Will you provide installation services?

If you need, we can arrange professional technicians and engineers to install and debug on site.

Other Products

|

|

Hot Searches