- Product Details

- {{item.text}}

Quick Details

-

Ejector Stroke(mm):

-

145 mm

-

Ejector Force(kN):

-

77 kN

-

Theoretical Shot Volume(cm³):

-

425 cm³

-

Injection Rate (g/s):

-

503 g/s

-

Injection Weight (g):

-

379 g

-

Screw diameter (mm):

-

52 mm

-

Screw L/D Ratio:

-

22

-

Weight (KG):

-

10500 kg

-

Place of Origin:

-

Guangdong, China

-

Open Stroke(mm):

-

550 mm

-

Model Number:

-

KF300-S6

-

Brand Name:

-

Powerjet

-

Power (kW):

-

21 kW

-

Product name:

-

Plastic Injection Moulding Machine

-

Keyword:

-

Energy Saving

-

Used for:

-

plastic commodity making injection molding machine

-

Function:

-

Plastic Injection Molding Machinery

-

Machiner Dimensions(m):

-

6.7*1.9*2.2

-

Application:

-

thin-wall products

-

Machine weight:

-

10.5T

-

Pump Motor Power:

-

17.5Mpa

-

Platen SIze:

-

620*570mm

Quick Details

-

Distance between Tie Bars(Width)(mm):

-

900mm

-

Distance between Tie Bars(Height)(mm):

-

950mm

-

Mold Height(mm):

-

250 - 600 mm

-

Ejector Stroke(mm):

-

145 mm

-

Ejector Force(kN):

-

77 kN

-

Theoretical Shot Volume(cm³):

-

425 cm³

-

Injection Rate (g/s):

-

503 g/s

-

Injection Weight (g):

-

379 g

-

Screw diameter (mm):

-

52 mm

-

Screw L/D Ratio:

-

22

-

Weight (KG):

-

10500 kg

-

Place of Origin:

-

Guangdong, China

-

Open Stroke(mm):

-

550 mm

-

Model Number:

-

KF300-S6

-

Brand Name:

-

Powerjet

-

Power (kW):

-

21 kW

-

Product name:

-

Plastic Injection Moulding Machine

-

Keyword:

-

Energy Saving

-

Used for:

-

plastic commodity making injection molding machine

-

Function:

-

Plastic Injection Molding Machinery

-

Machiner Dimensions(m):

-

6.7*1.9*2.2

-

Application:

-

thin-wall products

-

Machine weight:

-

10.5T

-

Pump Motor Power:

-

17.5Mpa

-

Platen SIze:

-

620*570mm

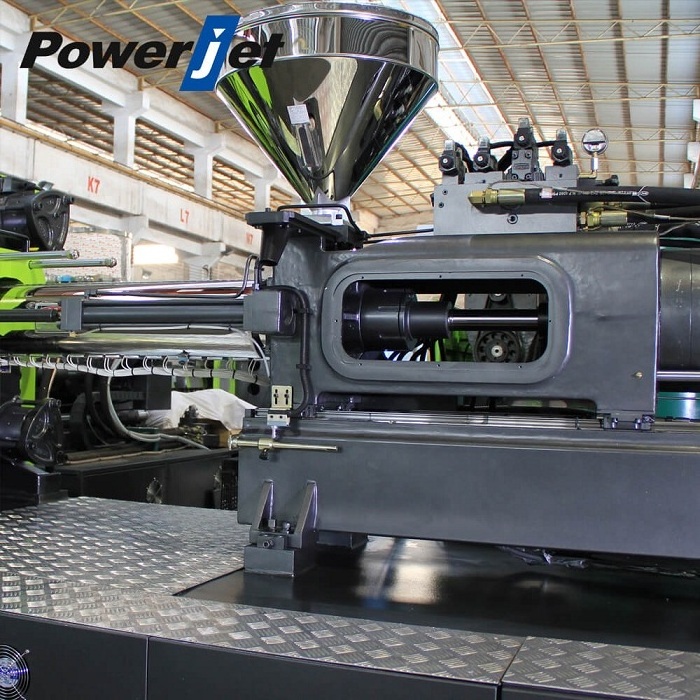

Powerjet provides specialized injection molding machines dedicated to plastic cutlery products, such as: plastic spoons, forks and knives, plastic d isposable food containers, plastic disposable teacup, etc . We have improved the injection system to makes thin-wall products easier to solidify, and can save 30-50% of energy compared to common models.

KF series is our specialized injection molding machine for thin-wall products

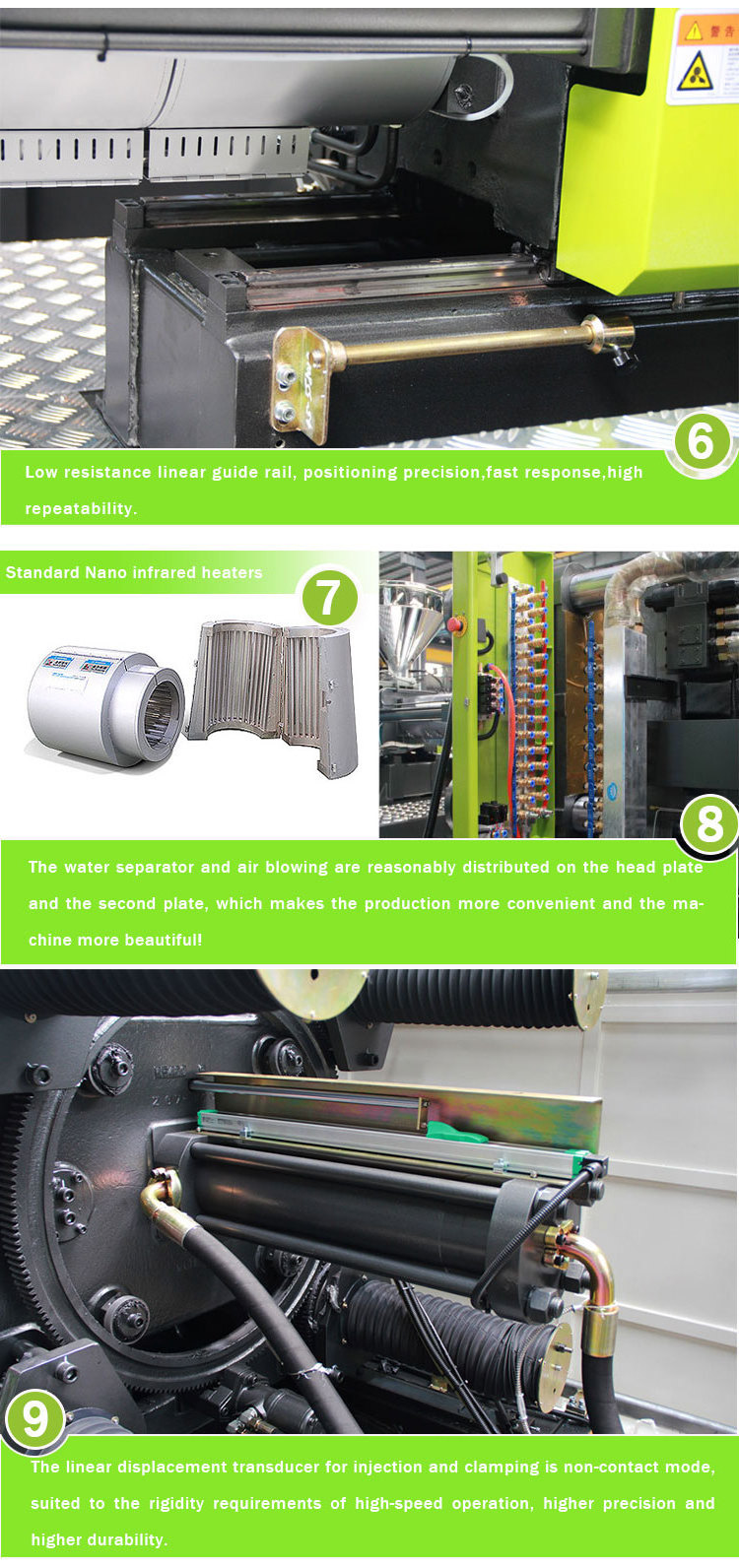

FEATURES:

1:

Energy-Saving 30%~50%

Servo motor with energy-saving controlled hydraulic systems can save electricity up to 30%~50%.

2:

Low Temperature Injection

Low-Temperature Injection Makes More Energy Saving And Keeping Products With High Tenacity And Toughness By Our Innovative Plasticizing System.

3:

Low Pressure Injection

Low-Pressure Injection To Gain Better Mechanical Protection And Longer Mould Service Life. Also Makes Molding Products With Low Stress And Deformation.

4:

Fast Response Speed

Optimized Control System Response Speed Let Our Shooting Rate Reaching The Best Short Time Within 0.3 Seconds.