Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Hebei, China

-

Model Number:

-

stainless steel wire mesh

-

Brand Name:

-

stainless steel wire mesh

-

Product name:

-

galvanized steel wire mesh

-

Width:

-

0.5-2m

-

Length:

-

10-30m

-

Weaving type:

-

plain weave,dutch weave,twill weave

-

Wire diameter:

-

customer's requirement

-

Mesh:

-

1-3500mesh

-

Surface treatment:

-

Hot Dipped Galvanized

-

Usage:

-

Screening

-

Sample:

-

Avaliable

Quick Details

-

Material:

-

galvanized wire,black steel, manganese steel

-

Type:

-

Wire Cloth

-

Application:

-

Screen

-

Place of Origin:

-

Hebei, China

-

Model Number:

-

stainless steel wire mesh

-

Brand Name:

-

stainless steel wire mesh

-

Product name:

-

galvanized steel wire mesh

-

Width:

-

0.5-2m

-

Length:

-

10-30m

-

Weaving type:

-

plain weave,dutch weave,twill weave

-

Wire diameter:

-

customer's requirement

-

Mesh:

-

1-3500mesh

-

Surface treatment:

-

Hot Dipped Galvanized

-

Usage:

-

Screening

-

Sample:

-

Avaliable

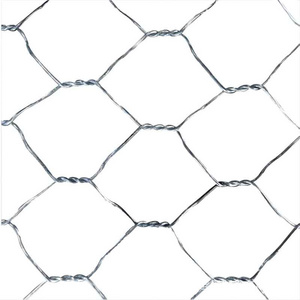

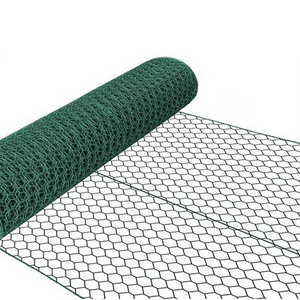

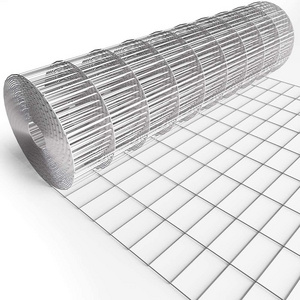

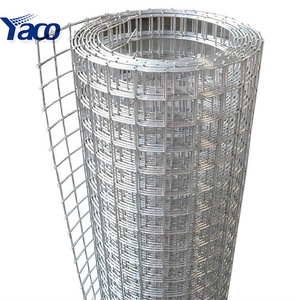

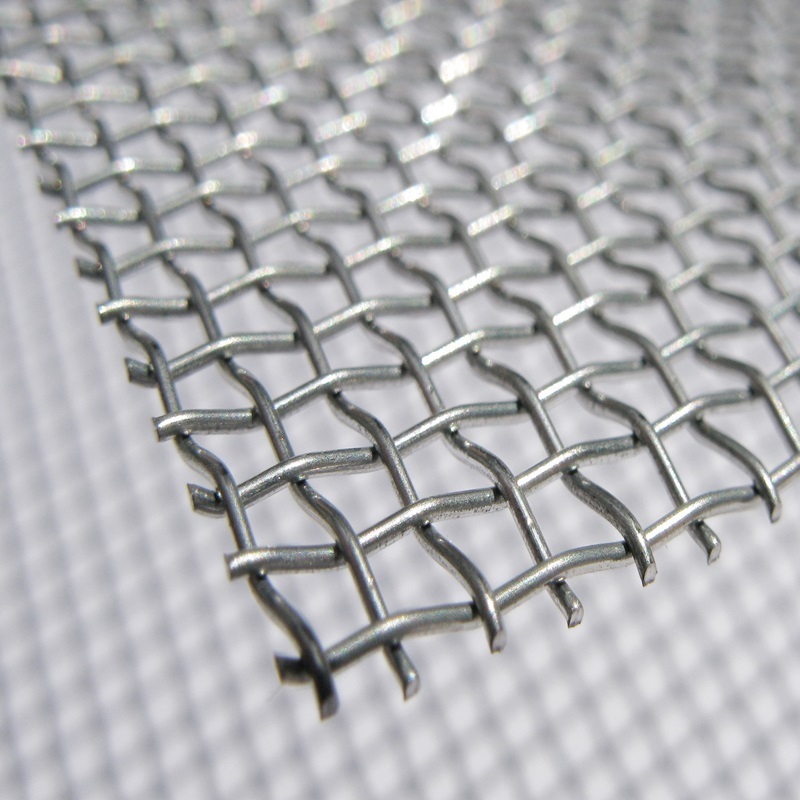

Galvanized Steel Wire Mesh

Galvanized steel wire mesh is made with mild steel wire pregalvanized via the electro galvanizing or hot dipped zinc plating. The Mild steel fine wire is then woven or welded into mesh nettings with different mesh density and sizes. Galv. wire mesh has two types: woven galvanized mesh and galvanized steel welded mesh.

Galvanised mild steel wire mesh in weaving style is mainly used for mining, coal development, building material and industries uses.

|

|

Galvanized Steel Wire Mesh-Specifications

Depending on the application, there are different materials best suited for the job. Among the most common in industrial applications is Galvanized, including cold galvanizing, electrogalvanizing and hot dipped galvanized. Galvanized is the standard for many industrial applications, due to its affordability and resilient characteristics, including:

— Corrosion resistance in multiple manufacturing environments

— Heat resistance

— Oxidation resistance

— Applicability for welding using the most common techniques

— Virtual lack of magnetivity (in an annealed condition)

Other available materials for wire mesh include:

— Stainless steel

— Aluminum

— Brass

— Bronze

— Copper

— Galvanized

— Monel

— Steel — Carbon

— Steel — Plain

|

Mesh Count Per Inch |

Wire diameter | Opening Width | Micron Size | Open Area | ||

| Inches | mm | Inches | mm | %Percent | ||

| 8 | 0.028 | 0.711 | 0.097 | 2.464 | 2464.0 | 60.2 |

| 10 | 0.025 | 0.635 | 0.075 | 1.905 | 1905.0 | 56.3 |

| 12 | 0.023 | 0.584 | 0.080 | 1.532 | 1532.0 | 52.4 |

| 14 | 0.020 | 0.508 | 0.051 | 1.306 | 1306.0 | 51.8 |

| 16 | 0.018 | 0.457 | 0.0454 | 1.130 | 1130.0 | 50.7 |

| 18 | 0.017 | 0.432 | 0.039 | 0.979 | 979.0 | 48.2 |

| 20 | 0.016 | 0.406 | 0.034 | 0.864 | 864.0 | 46.2 |

| 24 | 0.014 | 0.356 | 0.028 | 0.703 | 703.0 | 44.1 |

| 30 | 0.011 | 0.330 | 0.020 | 0.516 | 516.0 | 17.2 |

| 35 | 0.011 | 0.279 | 0.018 | 0.446 | 446.0 | 37.8 |

| 40 | 0.010 | 0.254 | 0.015 | 0.381 | 381.0 | 36.0 |

| 50 | 0.009 | 0.229 | 0.011 | 0.279 | 279.0 | 30.3 |

| 60 | 0.0075 | 0.1905 | 0.0092 | 0.2328 | 233.0 | 30.3 |

— Can be used in a wide range of industrial and commercial uses.

— Can be made of stainless steel or many other metals and alloys.

— Comes in a variety of weave and crimp types.

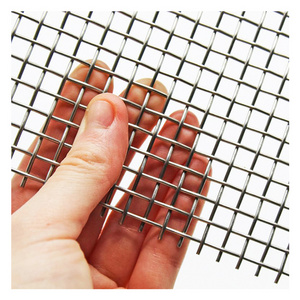

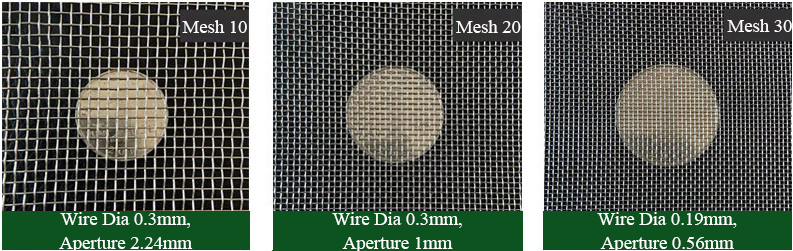

>>>The following pictures for your reference

|

Mesh10 Wire Diameter 0.3mm Aperture 2.24mm |

Mesh20 Wire Diameter 0.3mm Aperture 1mm |

Mesh30 Wire Diameter 0.19mm Aperture 0.56mm |

|

Mesh40 Wire Diameter 0.19mm Aperture 0.45mm |

Mesh50 Wire Diameter 0.15mm Aperture 0.35mm |

Mesh60

Wire Diameter 0.15mm Aperture 0.28mm |

|

Mesh80 Wire Diameter 0.12mm Aperture 0.2mm |

Mesh100 Wire Diameter 0.1mm Aperture 0.15mm |

Mesh120 Wire Diameter 0.09mm Aperture 0.12mm |

|

Mesh150 Wire Diameter 0.06mm Aperture 0.11mm |

Mesh300 Wire Diameter 0.04mm Aperture 0.04mm |

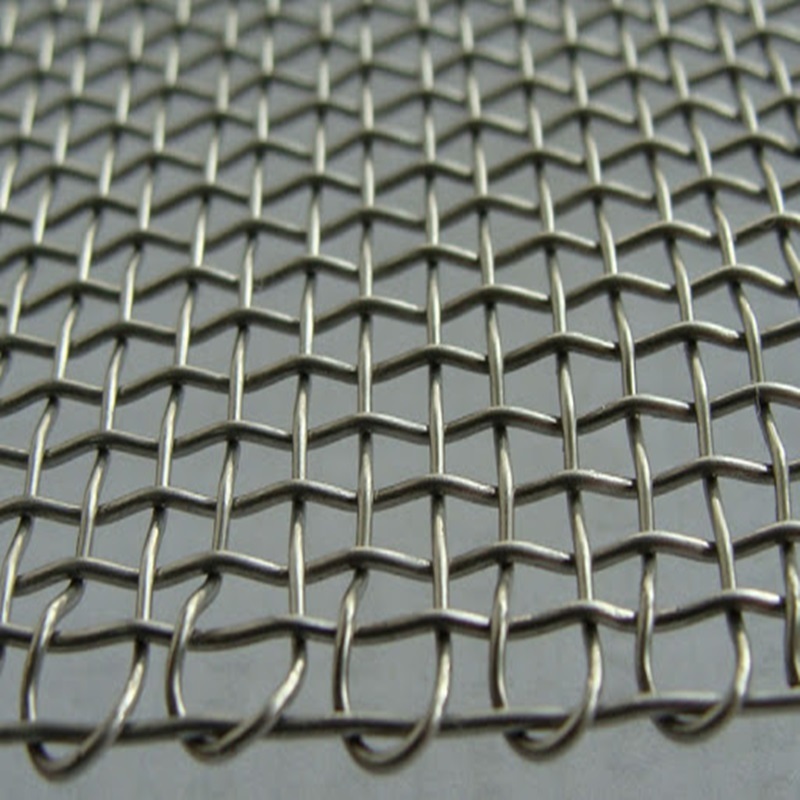

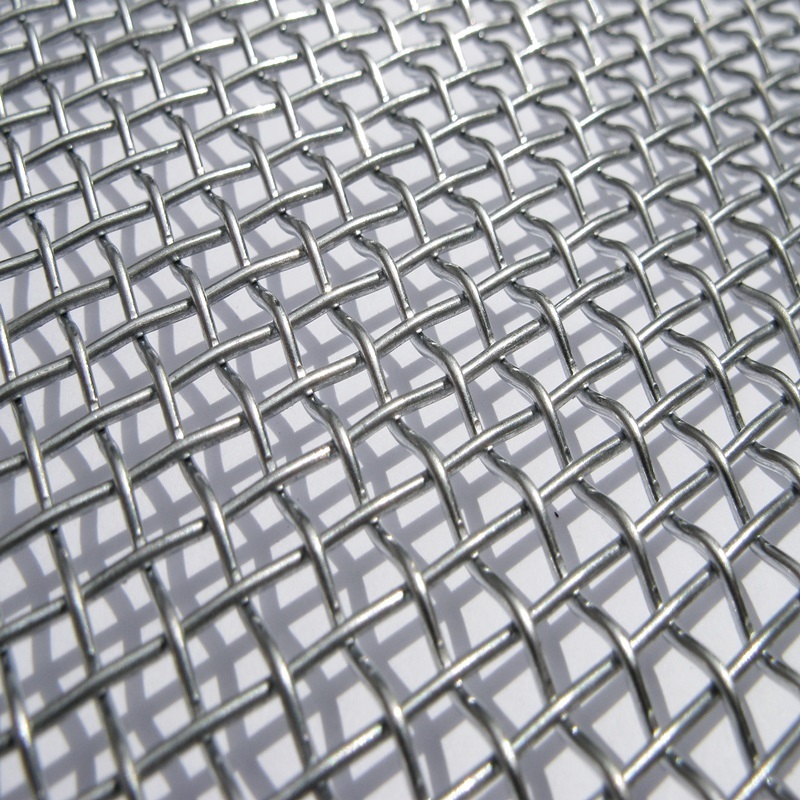

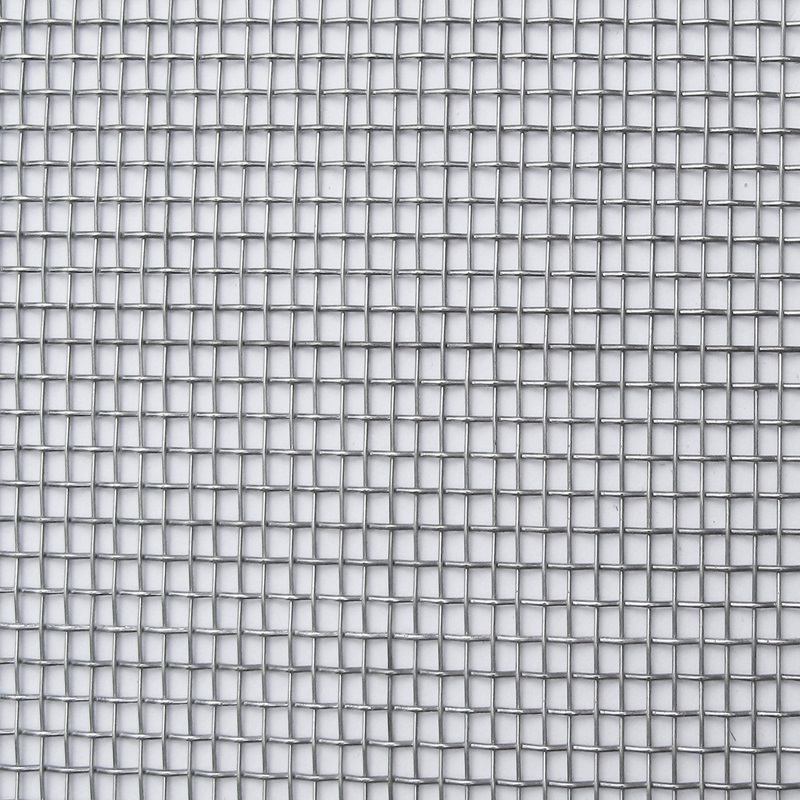

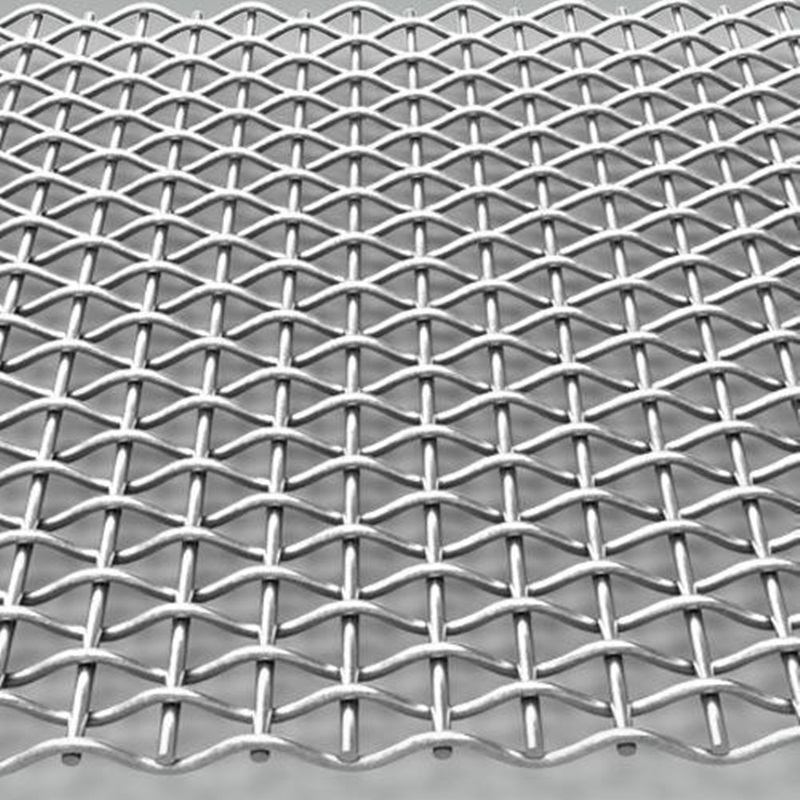

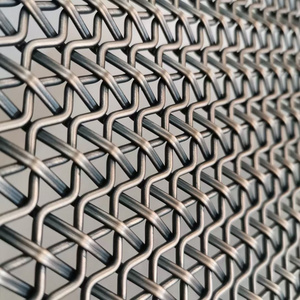

Galvanized Steel Wire Mesh-Weave Type

Different industrial and commercial applications require different weave types.

|

Plain Square Woven Wire The most common wire weave, with the same diameter warp and shute wires, woven in a simple over and under pattern. This style produces screens with the same mesh count in both directions. |

|

Twill Square Woven Wire Each shute wire typically passes over two warp wires and under two producing square openings. Twill weave can be made from larger-diameter wires than would be possible in plain square weave, to obtain greater strength, density, or corrosion resistance. |

|

Plain Dutch Woven Wire This weave style is woven in a plain, over and under pattern. The plain dutch woven wire style is a very tight weave because a thinner, smaller diameter shute wire is used. Dutch weaves do not have a straight-through, clear opening like most plain weave styles. Instead, the weave style creates a tortuous path through which very fine filtration and particle retention can be achieved. Dutch weaves may be specified by a “mesh count” or an “absolute filter rating.” |

|

Dutch Twill Weave Wire This weave style is similar to Plain Dutch, except it is woven in Twill style. Each wire passes over two wires then under two wires, still utilizing a smaller-diameter shute wire, allowing an even tighter weave and even finer filtration than the Plain Dutch weave. |

|

Reverse Dutch Weave Wire This weave style is the same weave as Plain Dutch, except the warp and shute wires are reversed. The larger shute wires are woven closer together than would usually be seen in a Plain Dutch weave. |

|

Rectangular or “Off-Count” Weave Wire This is a Plain weave wire cloth, woven in an over and under pattern with a different number of wires in the warp and shute direction, which yields a rectangular opening wire cloth. Rectangular openings are often used in sifting and sizing operations to increase product “through” capacity, with minor sacrifices in accuracy. To reduce material costs, off-count wire mesh may be substituted for square wire mesh in some applications that do not require a high level of accuracy. Some wire cloth vendors will substitute off-count wire cloth when certifications are not specified by the manufacturer. For example, a 90 x 100 mesh may be substituted for 100 x 100. |

|

Stranded Weave Wire Usually woven in the Plain Square style, each warp and shute “wire” is composed of a “bunch” or “group” of small-diameter wires, which are woven into a finished product. |

Galvanized Steel Wire Mesh-Producing Department

Galvanized Steel Wire Mesh-Applications

Assortments :

Galvanized Steel Wire Mesh, hot-dipped galvanized after weaving

Galvanized Steel Wire Mesh, hot-dipped galvanized before weaving

Galvanized Steel Wire Mesh, electro galvanized after weaving

Galvanized Steel Wire Mesh, electro galvanized before weaving

Contact Us

lisahan(at)yongkunmetal(dot)com

+86-159-3112-7593

+86-155-3018-8180