A Full Automatic Large Volume Bottle Molding Machine is dedicated to producing large water bottles ranging between 5l to 20l. It comes with pneumatic control, a convenient LCD touchscreen operation, and offers error-free production with a minimum cycling time.

- Product Details

- {{item.text}}

Quick Details

-

Bottle Volume(ml):

-

600 ml

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

MAIWEI

-

Year:

-

NEW

-

Voltage:

-

380V/50HZ

-

Dimension(L*W*H):

-

CUSTOMIZED

-

Hollow part volume:

-

CUSTOMIZED

-

Clamping Force (kN):

-

215

-

Power (kW):

-

20

-

Weight (KG):

-

3500 KG

-

Product name:

-

Blow moulding machine

-

Blow Moulding Type:

-

Extrusion Blow Moulding

-

Clamping force:

-

38KN

-

Mold Stroke:

-

138-368mm

-

Blowing pressure:

-

0.6-0.8Mpa

-

Certification:

-

ISO

-

high pressure air consumption:

-

3.6/30

Quick Details

-

Neck Diameter(mm):

-

50 mm, 38

-

Max.Bottle Diameter(mm):

-

68 mm, 105

-

Max.Bottle Height(mm):

-

260 mm

-

Bottle Volume(ml):

-

600 ml

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

MAIWEI

-

Year:

-

NEW

-

Voltage:

-

380V/50HZ

-

Dimension(L*W*H):

-

CUSTOMIZED

-

Hollow part volume:

-

CUSTOMIZED

-

Clamping Force (kN):

-

215

-

Power (kW):

-

20

-

Weight (KG):

-

3500 KG

-

Product name:

-

Blow moulding machine

-

Blow Moulding Type:

-

Extrusion Blow Moulding

-

Clamping force:

-

38KN

-

Mold Stroke:

-

138-368mm

-

Blowing pressure:

-

0.6-0.8Mpa

-

Certification:

-

ISO

-

high pressure air consumption:

-

3.6/30

Products Description

1.Brief Introduction

2.Features and Advantages

●A grease lubricating unit prevents the wearing and tearing of mechanical parts.

●There is an air storage unit for stabilizing and maintaining the air pressure.

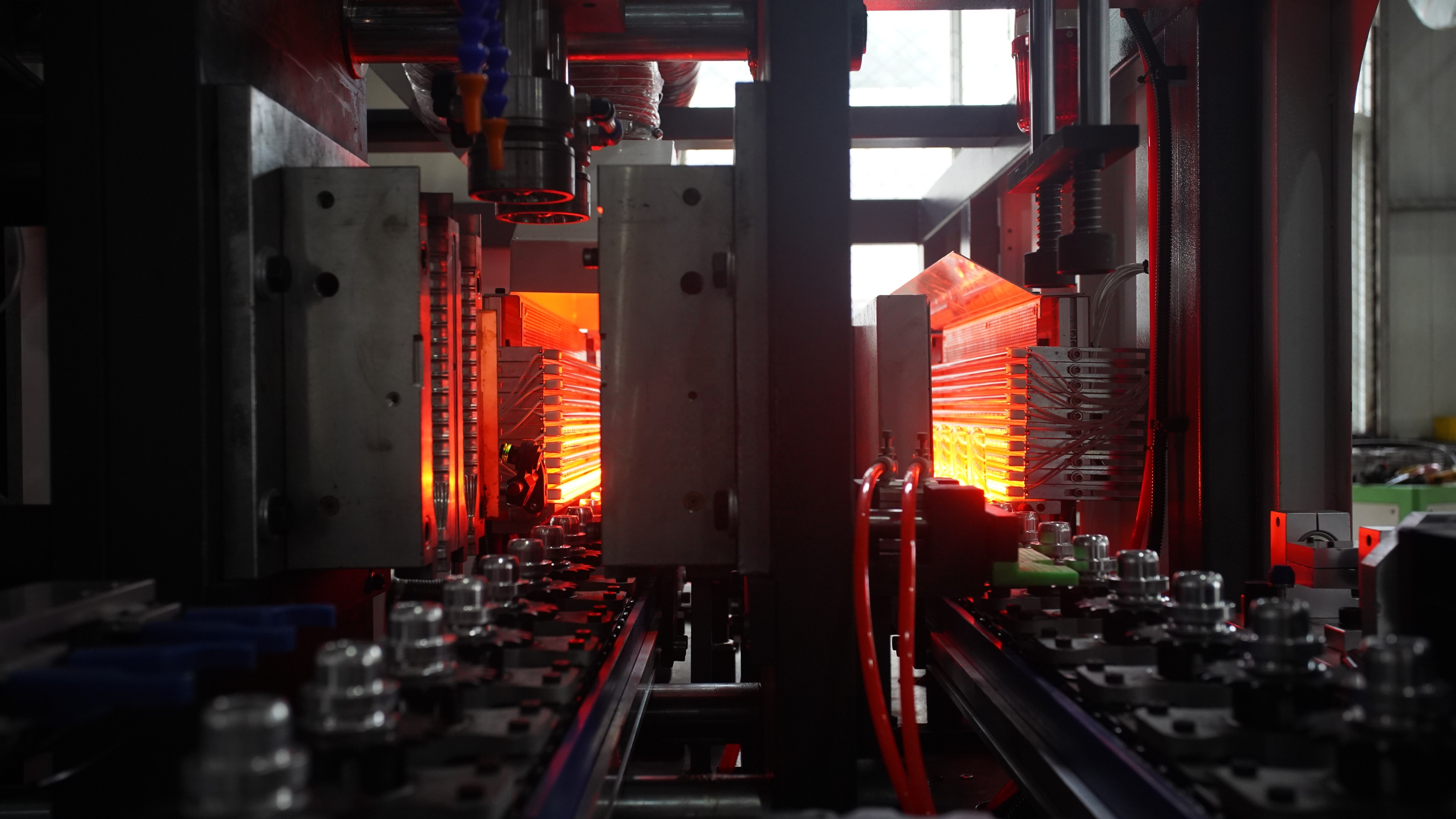

●The blowing process is more intense and requires deep heating because the preforms are heavy and thick.

●The efficient and automatic conveyor allows equal distribution and reduces the chance of any error.

●A large volume bottle molding is ergonomic because it utilizes the used air through a highly efficient air system.

3.

Main Technical Parameters

|

|

Model

|

Unit

|

MW-D5L2

|

MW-D10L2

|

MW-F25L-1

|

|

|

|

||||

|

Clamping Syatem

|

Number of cabity

|

cavities

|

2

|

2

|

1

|

|

|

|

||||

|

|

Calmping unit

|

KG

|

65000

|

80000

|

65000

|

|

|

|

||||

|

|

mold stroke

|

mm

|

220

|

260

|

320

|

|

|

|

||||

|

|

stretching stroke

|

mm

|

350

|

450

|

460

|

|

|

|

||||

|

|

bottom stroke

|

mm

|

50

|

50

|

50

|

|

|

|

||||

|

|

Cavitv pitch

|

mm

|

220

|

240

|

300

|

|

|

|

||||

|

|

number of holder

|

PCS

|

80

|

80

|

48

|

|

|

|

||||

|

Container

|

Max.container volume

|

ml

|

6000

|

100000

|

25000

|

|

|

|

||||

|

Container

|

Max.container height

|

mm

|

350

|

420

|

460

|

|

|

|

||||

|

|

Max.container diameter

|

mm

|

180

|

220

|

230

|

|

|

|

||||

|

|

Max.preform height

|

mm

|

200

|

240

|

240

|

|

|

|

||||

|

|

Max.neck diameter

|

mm

|

45

|

65

|

65

|

|

|

|

||||

|

Theoretical

|

Theoretical

|

B/H

|

1800

|

1400

|

600

|

|

|

|

||||

|

Electrical Systeem

|

Heating oven qty

|

PCS

|

4*4

|

4*4

|

4*4

|

|

|

|

||||

|

Electrical Systeem

|

Number of lamp

|

PCS

|

4*10

|

4*12

|

4*12

|

|

|

|

||||

|

|

Heating Power

|

KW

|

72

|

72

|

72

|

|

|

|

||||

|

|

Installed Power

|

KW

|

82

|

82

|

80

|

|

|

|

||||

|

|

Voltage

|

V

|

380/50HZ

|

380/50HZ

|

380/50HZ

|

|

|

|

||||

|

Air System

|

Operating Pressure

|

mpa

|

0.7-0.9

|

0.7-0.9

|

0.7-0.9

|

|

|

|

||||

|

|

Blowing Pressure

|

mpa

|

2.5-3.5

|

2.5-3.5

|

2.5-3.5

|

|

|

|

||||

|

|

high pressure air consumption

|

L/min

|

4.8/30

|

6.0/30

|

4.0/30

|

|

|

|

||||

|

|

power

|

KW

|

60

|

60

|

44

|

|

|

|

||||

|

Chiller Systeem

|

power

|

HP

|

5

|

5

|

5

|

|

|

|

||||

|

Machine

|

machine dimension

|

M

|

4.0*1.8*2.2

|

4.5*2.0*2.2

|

4.0*1.8*2.2

|

|

|

|

||||

|

Machine

|

machine weight

|

KG

|

4500

|

5500

|

4500

|

|

|

|

||||

Details Images

Products Shows

The main applications include mineral water bottles, juice, and drinking water bottles.

Product packaging

1. Blowing molding machine use wooden cases packaging

2. Accessories machines use wooden cases

3. Blowing mould can install onto blowing machine or seperately packed inside wooden boxes

Related Product

Hot Searches