- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V / 380V

-

Weight:

-

400kg

-

Dimension(L*W*H):

-

DN800x1000

-

sterilization capacity:

-

80Liter~ 3000Liter

-

autoclave / retort diameter:

-

DN400~DN1500

-

autoclave / retort Length:

-

600~6000mm

-

construction material:

-

SS304

-

sterilization temperature:

-

110~ 125 degree C

-

sterilization pressure:

-

0.1~0.35Mpa

-

suitable for:

-

food in cans, glass jars, bottles and doypaclk

-

heating medium:

-

steam / electric / hot water

-

sterilization temperature control:

-

automatic contro / semi-automatic control

-

pressure control:

-

manual / automatic

-

Certification:

-

CE ISO

Quick Details

-

Marketing Type:

-

full automatic control

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Ranking

-

Voltage:

-

220V / 380V

-

Weight:

-

400kg

-

Dimension(L*W*H):

-

DN800x1000

-

sterilization capacity:

-

80Liter~ 3000Liter

-

autoclave / retort diameter:

-

DN400~DN1500

-

autoclave / retort Length:

-

600~6000mm

-

construction material:

-

SS304

-

sterilization temperature:

-

110~ 125 degree C

-

sterilization pressure:

-

0.1~0.35Mpa

-

suitable for:

-

food in cans, glass jars, bottles and doypaclk

-

heating medium:

-

steam / electric / hot water

-

sterilization temperature control:

-

automatic contro / semi-automatic control

-

pressure control:

-

manual / automatic

-

Certification:

-

CE ISO

back prerssure autoclave small scale autoclave description

canned food, especially canned meat need to be fully sterilized in order to get an extended shelf life udner ambient temperature. In order to get the canned food fully sterilized, we need to use autoclave, or retort. we also call it as sterilizer retort, or retort sterilizer. or autocalve sterilizer. You can finish the sterilization process in an autoclave.

Ranking machinery offer autoclave or retort with both small scale and large scale. the smallest autoclave can be 60Liter and the biggest autoclave can be 6000Liter or more. For smale scale autoclave, most of our users choose electric heating medium. Electric heating autoclave / retort comes with a group of interior heating elements which immersed in water during sterilization process. When sterilization, heating elements will turn water into steam and an exterior water circulation pump will circulate hot water from retort chamber bottom to the top side and spray onto the canned food to be sterilized.

Electric heating autoclave / retort vertical autoclave DN400x500 for laboratory

steam heating type autoclave use exterior steam source

Different with the electric heating autoclave, steam heating autoclave usually comse with big capacity. No heating selements existing in a steam heating autoiclave because the heating medium for this type of autoclave retort is existing steam source from a steam generator.

sterilization basket / tray

PLC control type autoclave

basket or try in autoclave is a container in which you will place your product to during the sterilization process.

- sterilization basket and dolly are available for both steam autoclave and electric autoclave

- stainless steel tray

- stainless steel dolly

- the size of the sterilization tray / basket are custmoized

- the quanity of the tray and trolley are customized

Autoclave Pipeline

autoclave comes with steam inlet pipe, water inlet and outlet pipe, compressed aire inlet pipe and / or water circulation pipe. Pipeline for single vessly type autoclave is much more simple than double vessel autoclave.

Ranking Machinery offer the necessary pipeline together with your autoclave.

Pressure gauge for autoclave

Ranking Machinery will offer you one or two pcs pressure gauge together with the autoclave retort.

sometimes, extra pressure gauges will be offered under request.

for automatic contrl autoclave, there will be prerssure sensor on the retort chamber. working pressure can be read on the control touch screen or LCD screen as well.

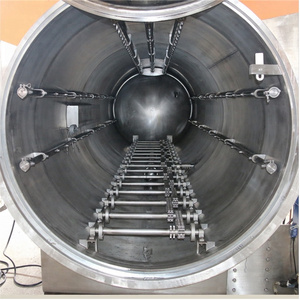

steam spray pipe on autoclave

steam spray pipe usually installed on top of the sterilizer chamber. It is a stainless steel pipe with two raw of aligned holes on the lower surface. when sterilization, steam will spray out like an umbrella towards the sterilization trays below. The steam spray pipe line will fully wet your product and send heat to all point of the retort chamber to make sure no deat angle existing in the autoclave chamber.

Both steam heating type autocalve and electric heating type autoclave equipped with a steam spray pipe. it is not only for steam, but also for water or steam & watrer mixer.

hot water vessel for double vessel autocalve

this is a hot water storage tank, it is fixed on top of an electric heating autocalve doubel vessel type. you can see the temperature probe, pressure gauge, safety valve as well the level meter in this picture.

The function of this hot water vessel is to pre heating the sterilization water in advance when users loading canned product into the sterilization chamber. The other function is to collect hot water after sterilization. with this water vessel on you autoclave, you will spend less time on each sterilization cycle. it is an energy-saving device.

autoclave temperature & pressure control

autocalve can be semi-manual control type or automatic control type. with semi automatc control system, you preset the sterilization temperature and holding time into the temperature gauge and timer, start the heating manually, then system will control the temperature and time automatically. during the sterilization process, you will need to control the pressure manually.the cooling process is also finished manually.

automatic control type autoclave will control temperature, pressure, sterilization time, cooling temperature all by programe. user's do not need to watch the sterilization process after the figures was preset into the automatic control system.

autoimatic control autoclave use Simense touch screen or other local brand touch screen or button type LCD.

date logger or papper less recorder is optional.

Autoclave timer

* 1 to 60 minutes Final Countdown

* easy to preset

* automatic alarming optional

Dgital type Temperature gauge

* with LCD screen

* 0~150 degree range

* easy to operate

1. After the sterilization process of your back prerssureautocalve / retrot, will the canned food get a long shelf life?

2. What is the best sterilization temperature for our vacuum packed beans and bottles food?

Fod different product and package, the sterilization temperature may be different. user's will need to find out the most suitable sterilization temperature. Temperatures of 110°C will kill most Bacillus spores1 within a short time. In the case of Clostridium temperatures of up to 121°C are needed to kill the spores within a relatively short time. Ranking Machiner can help you to find out the most suitable sterilization temperature and sterilization time as well as the sterilization pressure within a few sterilization cycles.

3. What is the sterilization process for canned fish?

The

sterilization process

in the canned product can be subdivided into three phases see this picture below please. By means of a heating medium (Hot water or steam) the canned food temperature is increased from ambient to the required sterilization temperature (

phase 1 = heating phase

). This temperature is maintained for a defined time (

phase 2 = holding phasing or sterilization phase

). In (

phase 3 = cooling phase

) the temperature in the can is decreased by introduction of cold water into the autoclave / retort sterilizer. Please contact Mr. Cheng from Ranking Machine ( whatsapp + 86 180 7213 8651 or Email - tcmachine(at)outlook.com) for more detailed information of our autoclave or retort / sterilizer.

4. Please tell me more about your small scale autoclave / retort sterilzier

Simple small autoclaves are usually vertical autoclaves (

see the picture bleow

) with the lid on top. Through the opened lid the canned products to be sterilized are loaded into the small scale autoclave/ vertical autoclave. The cans are normally placed in metal sterilization baskets. Ranking Machinery whatsapp +8618072138651 offer steainless steel sterilization baskets. The baskets are placed in the vertical autoclave, either singly or several stapled on top of each other. Before starting the sterilization, the lid must be firmly locked onto the body of the autoclave.

Vertical autoclave vertical retort sketch

The autoclave and lid are designed to withstand pressures up to

5.0 bar

(please send emails to tcmachine(at)outlook.com to get the pressure/temperature relation table ). These types of small scale vertical retorts or autoclaves are best suited for smaller operations as they do not require complicated supply lines and Ranking Machinery will offer this kind of vertical autoclave to you at affordable prices.

5. large autoclave (back pressure type horizontal autoclave with 2000L to 10,000L capacity)

Larger autoclaves that Ranking Machinery offered are usually horizontal and loaded through a front lid (see the picture below please). In order to facilitate the loading and unloading of the goods to be sterilized, Ranking Machinery will offer you one pair of dolly together with the sterilization basket. All dolly and sterilization basket are made of stainless steel.

Autoclave retort front lid

large autoclave (horizontal autoclaves) that use a frount lid.

n

ot only Large autoclave retort use front lid, some middle sized autoclaves also use this same door structure

.

middle and small autoclave (horizontal autoclaves) that use a frount lid, for example

1. DN800x1000 electric heating autoclave

2. DN900x1500 electric heating autoclave

3. DN1100x2000 water spray type autoclave

4. DN1200x3000L water rotary type autoclave

6. for meant and beans in glass jar / glass bottle, what kind of autoclave do you suggest?

accoreding to our years of experiance in autoclave production, and based on our user's feedback in the past decades, the most suitable autoclave for mean in tin can and glass jar or glass bottles will be a double vessel autoclave water immersion type or with rotary system .

Horizontal autoclaves / horizontal retort sterilizer can be built as single or double vessel system. Ranking Machinery whatsapp +8618072138651 , Email- tcmachine(at)outlook.com.The double vessel systems have the advantage that the water is heated up in the upper vessel to the sterilization temperature and released into the lower (processing) vessel, when it is loaded and hermetically closed. Using the two–vessel system, the heat treatment can begin immediately without lengthy heating up of the processing vessel and the hot water can be recycled afterwards for immediate use in the following sterilization cycle.

rotary type autoclave / retort

rotary type autoclave suitable for meant and beans in glass jar, tin can, vacuum package, doypack, as well as glass bottles. With the rotary system, all the goodds will turn over and over in the autoclave chamber during the sterilization process which lead to a high cooking effiency and cooling phasw will also much more fast. Rotary type autoclave mainly used to the sterilization of thick product or canned / bottles product.