- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

500-005-2

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

chemcola

-

Model Number:

-

PF-901

-

Application:

-

Grinding wheel,Brake Pads,Clutch plate

-

free sample:

-

within 2kg

-

delivery time:

-

one week

-

MOQ:

-

5tons

-

Material:

-

phenol formaldehyde resin

-

video inspection:

-

workable

-

Gel time:

-

40-120

-

Characteristic:

-

good fluidity, high bonding strength

-

color:

-

white, brown

-

Packing:

-

25kg/bag

Quick Details

-

CAS No.:

-

9003-35-4

-

Other Names:

-

synthetic resin

-

MF:

-

C8H8O2

-

EINECS No.:

-

500-005-2

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

chemcola

-

Model Number:

-

PF-901

-

Application:

-

Grinding wheel,Brake Pads,Clutch plate

-

free sample:

-

within 2kg

-

delivery time:

-

one week

-

MOQ:

-

5tons

-

Material:

-

phenol formaldehyde resin

-

video inspection:

-

workable

-

Gel time:

-

40-120

-

Characteristic:

-

good fluidity, high bonding strength

-

color:

-

white, brown

-

Packing:

-

25kg/bag

Product catalog

Phenolic Resin:

Phenolic Resin For Coated Sands

Phenolic Resin For Friction Material

Phenolic Resin For Electronic Industry

Phenolic Resin For Refractory

Phenolic Resin For Molding Compound

Acetylene Tackifying Resin

Phenolic Resin For Heat Preservation Material

Phenolic Resin For Mine Filling

Phenolic Resin For Filter Paper

Epoxy Resin:

Phenol Novolac Epoxy Resin

BPF Epoxy Resin

Crystaline Epoxy Resin

Other Productions:

BPF

Product Description

Product Description:

The products have many advantages such as high thermal decomposing temperature, low

thermofade of high temperature, low content of free phenol, good fluidity, high soakage ability for fiber and

stuffing. And friction products have stable friction coefficient, high ability of thermo-recovery, and

low wearing, etc...Our products have been used for many frictional materials such as brake sheet,

brake shoe and clutch disk, etc...

thermofade of high temperature, low content of free phenol, good fluidity, high soakage ability for fiber and

stuffing. And friction products have stable friction coefficient, high ability of thermo-recovery, and

low wearing, etc...Our products have been used for many frictional materials such as brake sheet,

brake shoe and clutch disk, etc...

Phenolic resin for friction material

The products have many advantages such as high thermal decomposing temperature, low thermofade of high temperature, low content of

free phenol, good fluidity, high soakage ability for fiber and stuffing. And friction products have stable friction coefficient,

high ability of thermo-recovery, and low wearing, etc. Our products have been used for many frictional material such as brake

sheet, brake shoe and clutch disk,etc

The products have many advantages such as high thermal decomposing temperature, low thermofade of high temperature, low content of

free phenol, good fluidity, high soakage ability for fiber and stuffing. And friction products have stable friction coefficient,

high ability of thermo-recovery, and low wearing, etc. Our products have been used for many frictional material such as brake

sheet, brake shoe and clutch disk,etc

|

Grade No.

|

Appearance

(powder)

|

Gel time(S)

|

Fluidity(mm)

125℃

|

Water(%)

|

Mesh size

(200mesh,%) |

Modified or not

|

|

CPF-901

|

Light yellow

|

70-120

|

25-45

|

≤1.0

|

≥99

|

Phenolic resin

|

|

CPF-901A

|

Light yellow

|

60-115

|

25-40

|

≤1.5

|

≥99

|

|

|

CPF-9014

|

Light yellow

|

70-120

|

25-40

|

≤1.5

|

≥99

|

|

|

CPF-2123

|

Light yellow

|

35-85

|

25-50

|

≤1.5

|

≥98

|

|

|

CPF-2123A

|

Light yellow

|

40-90

|

25-60

|

≤1.5

|

≥98

|

|

|

CPF-9005

|

Light yellow

|

60-100

|

30-50

|

≤1.5

|

≥99

|

|

|

CPF-906

|

Light yellow

|

65-100

|

20-35

|

≤1.0

|

≥94

|

Acrylonitrile-butadiee latex modified

|

|

CPF-9068

|

Light yellow

|

80-110

|

25-35

|

≤1.0

|

≥98

|

|

|

CPF-902

|

Light yellow

|

65-110

|

30-50

|

≤1.0

|

≥98

|

Cashew modified

|

|

CPF-9019H

|

Light yellow

|

70-110

|

20-30

|

≤1.5

|

≥99

|

High temperature resistant resin

|

Phenolic resin for Coated sand

.

This series of products are mainly used for the preparation of coated sand in the foundry industry. The product is characterized

by good fluidity, fast polymerization speed, high bonding strength, low free phenol content, good shelling resistance and high

temperature resistance.

This series of products are mainly used for the preparation of coated sand in the foundry industry. The product is characterized

by good fluidity, fast polymerization speed, high bonding strength, low free phenol content, good shelling resistance and high

temperature resistance.

|

Grade No

|

Appearance

|

Softening point

(℃)

|

Gel time(S)

|

Fluidity(mm) 125℃

|

Free phenolic

|

Feature/Usage

|

|

CPF-103

|

Light yellow granular

|

88-92

|

28-35

|

70-90

|

≤3.5

|

Fast cure/mold core

|

|

CPF-104

|

Light yellow granular

|

90-94

|

38-46

|

70-90

|

≤4.0

|

General/mould or core

|

|

CPF-106

|

Light yellow granular

|

94-98

|

20-30

|

55-70

|

≤4.0

|

General/mould or core

|

|

CPF-106C

|

Light yellow granular

|

98-102

|

20-30

|

30-50

|

≤4.0

|

Fast cure

|

|

CPF-1380G

|

Light yellow granular

|

84-88

|

60-80

|

140-170

|

≤2.0

|

General/mould or core

|

|

CPF-1387

|

Light yellow granular

|

84-86

|

60-85

|

150-175

|

≤2.5

|

High strength

|

|

CPF-1388

|

Light yellow granular

|

90-93

|

80-110

|

130-150

|

≤0.5

|

High strength

|

|

CPF-1391

|

Light yellow granular

|

93-96

|

50-70

|

90-115

|

≤1.5

|

Low gas evolution rate

|

|

CPF-1391Y

|

Light yellow granular

|

94-96

|

80-120

|

>90

|

≤1.5

|

Cast steel

|

|

CPF-1393

|

Light yellow granular

|

89-92

|

60-85

|

130-170

|

≤2.0

|

High softening point,high strength

|

|

CPF-1395

|

Light yellow granular

|

98-102

|

50-70

|

60-100

|

≤2.0

|

Cast steel

|

|

CPF-1396

|

Light yellow granular

|

90-93

|

28-33

|

60-85

|

≤3.5

|

Cast steel

|

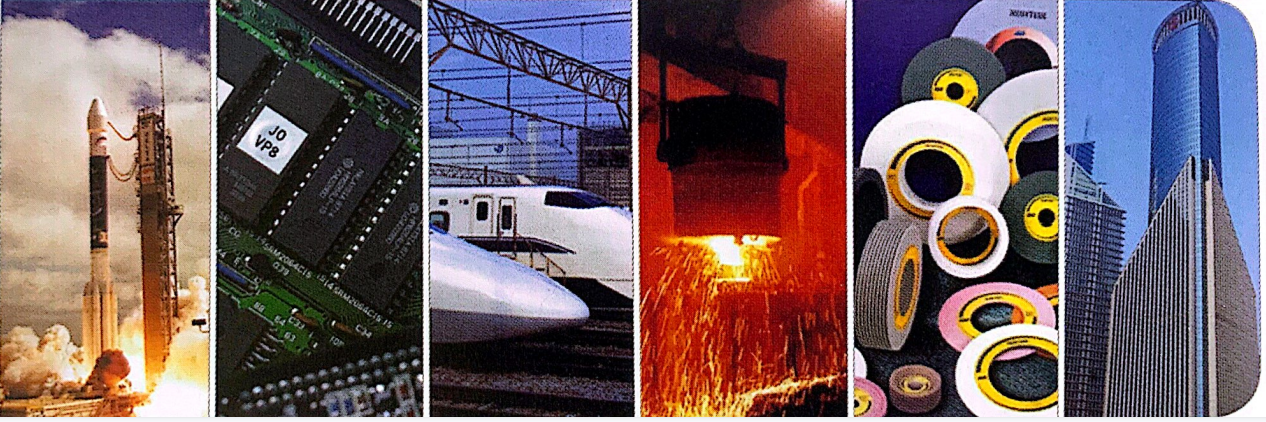

Application

Packing & Delivery

Packing:

By paper-plastic bags with one plastic bag inside, 25 kg/bag.

Storage condition:

Kept in dry, ventilated condition.

Sorage time :

6 months shelf under 25C.

Our Company

Our company mainly produces various phenolic resins, which are widely used in casting materials, friction materials, refractory materials, abrasives, rubber tires, electronic materials, phenolic foam insulation materials, mine filling materials, aerospace and other industries. The technology is at the leading domestic level. The annual production capacity is 60,000 tons. The products are not only sold well in the Chinese market, but also exported to South Korea, Russia, the United States, Australia and other countries. In 2012, the company took the lead in independently developing and building a "30,000-ton high-performance epoxy resin plant" approved by the Ministry of Industry and Information Technology of the People's Republic of China. Among them, bisphenol F and bisphenol F special epoxy resin products have filled the domestic large-scale industrial production. In one fell swoop, it entered the ranks of high-end epoxy resin manufacturing enterprises in China and became a pioneer in the development of special epoxy resins. The company established a research and development center in 2001, and there are 26 full-time research and development personnel, including 7 senior engineers and 9 engineers. The center was identified as Shandong provincial enterprise technology center in 2008, and was identified as Shandong phenolic resin engineering technology research center in 2009. It is the only provincial engineering technology research center in the domestic phenolic resin industry.

More Phenolic Resin :

Cashew modified

Phenolic Resin

Acrylonitrile-butadiene latexmodified Phenolic Resin

Acrylonitrile-butadiene latexmodified Phenolic Resin

High temperature resistant resin

Contact me for more information

Hot Searches