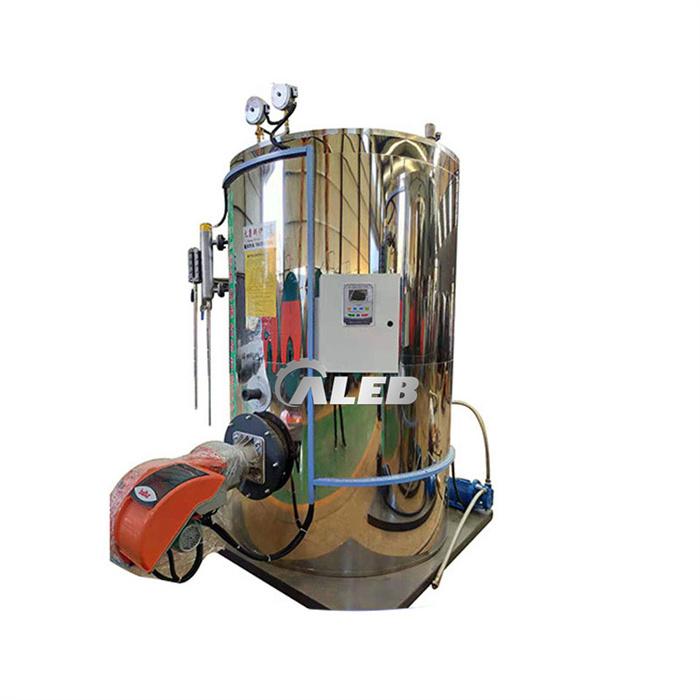

- Product Details

- {{item.text}}

Quick Details

Quick Details

-

Type:

-

Gas Burner

-

Weight (KG):

-

800

-

Place of Origin:

-

Henan, China

Products Description

steam generator

coal boilers are widely used in food factory, drinking factory, juice factory, sugar refinery, tire factory, soap factory, cement production, concrete production, paper-making, brick-making, carton plant, chemical fertilizer plant, feed mill, knit mill, tissue mill, textile mill, palm oil factory, gloves factory, alcohol plant, chicken processing plant, instant noodle plant, medical and chemical industries, etc

Product Paramenters

|

Model

|

ton capacity (t/h)

|

Rated pressure (MPa)

|

Steam temperature (℃)

|

Thermal efficiency (%)

|

Fuel consumption (kg/h)

|

Dimension L×W×H (cm)

|

Weight (t)

|

|

|

|

|

|

|

|

|

|

|

CE0.3-0.09

|

0.3

|

0.09

|

110

|

≥93

|

60

|

160*110*251

|

1.5

|

|

CE0.5-0.09

|

0.5

|

0.09

|

110

|

≥93

|

110

|

170*122*260

|

1.8

|

|

CE0.7-0.09

|

0.7

|

0.09

|

110

|

≥93

|

160

|

190*132*260

|

2.2

|

|

CE1-0.09

|

1

|

0.09

|

110

|

≥93

|

210

|

210*152*265

|

2.9

|

Details Images

FEATURES:

under the condition of no soot-blowing, the boiler can work full-load, high-efficiency and safety in long term.

2. The big and tall boiler furnace can be designed according to the different fuel to

improve the burning rate of fuel and remove black smoke.

3. All independent loop and reasonable coal boiler injected circulation are specially

designed and adopted for the hot water boilers. The medium speed in loop of heat surface is higher than national standard

4. Dust inertia separation at the furnace outlet can reduce exhaust gas concentration

and lessen abrasion of rear heat surface.

5. Compact structure makes its installation volume smaller than other types of boilers,

it will shorten installation period and lower boiler room cost.

6. Big water volume benefits for power-off protection, high ability suitable for load

changing.

Customer use case

Product packaging

Hot Searches