- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

According to different models

-

Weight:

-

4000 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Application:

-

Ore,cement,silicate,new building material,refractory material

-

Price:

-

negotiation

-

Color:

-

As customers' request

-

Flowchart:

-

Provide

-

Instalation:

-

Provide

-

Quality:

-

High Reputation

-

Certification:

-

CE,ISO,BV

Quick Details

-

Capacity(t/h):

-

0.5-180t/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

ZONEDING

-

Dimension(L*W*H):

-

According to different models

-

Weight:

-

4000 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Application:

-

Ore,cement,silicate,new building material,refractory material

-

Price:

-

negotiation

-

Color:

-

As customers' request

-

Flowchart:

-

Provide

-

Instalation:

-

Provide

-

Quality:

-

High Reputation

-

Certification:

-

CE,ISO,BV

Product Description

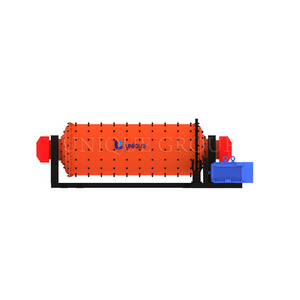

The ball milling machine is suitable for primary grinding (crushers + ball mill) and secondary grinding stages (crushers + rod mill + ball mill), and is used in conjunction with the crushers and beneficiation equipment in the mineral processing plant.

Its applicable materials include metal ores, non-metallic ores, cement clinker, slag, quartz sand, zircon sand, glass, ceramics, new building materials, etc. Thus, it is widely used in cement, building materials, fireproof materials, glass, ceramics, and other industries.

Φ2400×4500

Φ3200×4500

If you are interested in this, please contact us as soon as possible! We will provide you with more than 2 solutions for you to choose from.

|

Model

|

Speed (r/min)

|

Max. weight of balls (t)

|

Input size (mm)

|

Output size (mm)

|

Power (kw)

|

Capacity (t/h)

|

Weight (t)

|

|

Φ900×1800

|

37

|

1.8

|

≤15

|

0.075-0.89

|

15

|

0.5-2

|

3.4

|

|

Φ900×2100

|

37

|

2.3

|

≤15

|

0.075-0.4

|

18.5

|

0.4-2

|

3.9

|

|

Φ900×3000

|

35

|

3.85

|

≤25

|

0.075-0.4

|

30

|

1.1-2.5

|

7.78

|

|

Φ1200×2400

|

35

|

4.6

|

≤25

|

0.075-0.4

|

30

|

1.3-3.2

|

8.65

|

|

Φ1200×2800

|

35

|

5.4

|

≤25

|

0.075-0.4

|

37

|

1.5-3.7

|

10.02

|

|

Φ1200×4500

|

35

|

8.6

|

≤25

|

0.075-0.4

|

45

|

2.7-6.79

|

14

|

|

Φ1500×3000

|

29

|

9

|

≤25

|

0.047-0.4

|

75

|

3.3-8.2

|

14.12

|

|

Φ1500×3500

|

29

|

10.5

|

≤25

|

0.047-0.4

|

75

|

3.3-8.5

|

15.64

|

|

Φ1500×4500

|

29

|

13.5

|

≤25

|

0.047-0.4

|

90

|

4.5-12

|

20

|

|

Φ1500×5700

|

29

|

17

|

≤25

|

0.047-0.4

|

110

|

2.6-14

|

21.5

|

|

Φ1830×3000

|

24

|

13.5

|

≤25

|

0.047-0.4

|

135

|

4-15

|

28

|

|

Φ1830×3600

|

24

|

14

|

≤25

|

0.047-0.4

|

135

|

4-15

|

29

|

|

Φ1830×4500

|

24

|

20

|

≤25

|

0.047-0.4

|

155

|

4-19

|

32

|

|

Φ1830×7000

|

24

|

31.5

|

≤25

|

0.047-0.4

|

210

|

6-22

|

37.5

|

|

Φ2100×3000

|

22

|

18

|

≤25

|

0.047-0.4

|

210

|

6.4-28

|

40.79

|

|

Φ2100×3600

|

22

|

20

|

≤25

|

0.047-0.4

|

210

|

7-28

|

42

|

|

Φ2100×4000

|

22

|

21.5

|

≤25

|

0.047-0.4

|

210

|

7.6-28

|

43.45

|

|

Φ2200×3600

|

21.7

|

25

|

≤25

|

0.047-0.4

|

245

|

5.2-32

|

44

|

|

Φ2200×7000

|

21.7

|

46

|

≤25

|

0.047-0.4

|

380

|

15-38

|

63

|

|

Φ2400×3600

|

21

|

28

|

≤25

|

0.047-0.4

|

320

|

8-60

|

47

|

|

Φ2400×4500

|

21

|

35

|

≤25

|

0.047-0.4

|

380

|

8.5-60

|

70.5

|

|

Φ2700×3600

|

20.7

|

40

|

≤25

|

0.047-0.4

|

400

|

12-80

|

75.5

|

|

Φ2700×4500

|

20.7

|

48

|

≤25

|

0.047-0.4

|

450

|

12-90

|

102

|

|

Φ3200×4000

|

18

|

65

|

≤25

|

0.047-0.4

|

800

|

30-180

|

137

|

Note: Any change of technical data shall not be advised additionally.

Ball Mill Working Principle

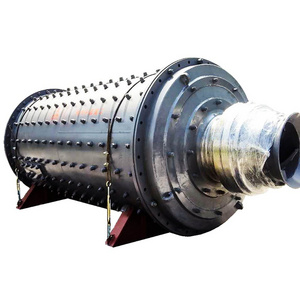

1. When the ball mill works, it is driven by the outer gear. Materials enter the mill through the feeding device. There are wear-resistant lining plates and grinding balls of different specifications in the cavity.

2. The rotation of the cylinder generates centrifugal force, which brings the ball to a certain height and then falls, causing a heavy impact and grinding effect on the material.

3. The powdery material is discharged through the discharging port to complete the grinding.

2. The rotation of the cylinder generates centrifugal force, which brings the ball to a certain height and then falls, causing a heavy impact and grinding effect on the material.

3. The powdery material is discharged through the discharging port to complete the grinding.

Common Ball Mil Solutions

Cunstomer Site

Hot Searches