- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

99.8%

-

Voltage:

-

220/380V

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

ORANGE

-

Weight:

-

3 KG

-

Function:

-

Juice Soda Water Beverage Beer Filling Packing

-

Material:

-

Stainless Steel

-

Filling volume:

-

200ml-2500ml

-

Control:

-

PLC+ Touch Screen

-

Filling accuracy:

-

99.8%

-

Bottle type:

-

PET Plastic Glass Bottle

-

MOQ:

-

1 Set

-

Processing Types:

-

Automatic Filling Production Line

-

Advantage:

-

10 Years Experiences

Quick Details

-

Machinery Capacity:

-

6000BPH, 9000BPH, 11000BPH, 22000BPH, 25000BPH, 30000BPH

-

Packaging Material:

-

Plastic, Glass, Other

-

Filling Material:

-

Beer, Milk, Water, Oil, Juice, Other

-

Filling Accuracy:

-

99.8%

-

Voltage:

-

220/380V

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

ORANGE

-

Weight:

-

3 KG

-

Function:

-

Juice Soda Water Beverage Beer Filling Packing

-

Material:

-

Stainless Steel

-

Filling volume:

-

200ml-2500ml

-

Control:

-

PLC+ Touch Screen

-

Filling accuracy:

-

99.8%

-

Bottle type:

-

PET Plastic Glass Bottle

-

MOQ:

-

1 Set

-

Processing Types:

-

Automatic Filling Production Line

-

Advantage:

-

10 Years Experiences

1. The sparkling beverage filling equipment adopts bottle neck holding transmission technology to realize fully automatic rinsing, filling and capping. This 3-in-1 sparkling beverage filling machine is mainly used for PET bottled gas contained drinks such as soda drinks.

2. This carbonated-drinks filling machine adopts advanced PLC control technology. The main electric elements adopt Mitsubishi, Omron, Siemens, etc international famous products. Each machine element that contacts with the liquid is made of high-quality stainless steel.

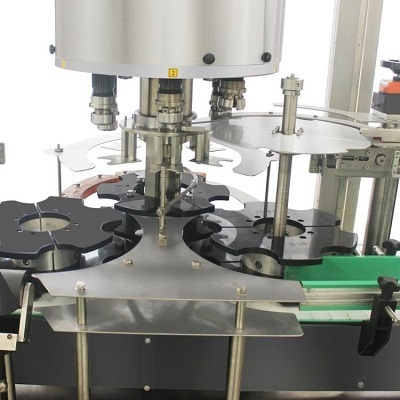

Rinsing section

This machine is a rotary bottle washer, mainly used for washing new bottles of beverages, water and other products. The bottle is then sent to the filling machine for product filling.

The PET bottle enters the equipment by the separating star wheel, the bottle mouth is clamped by the clamp and the turning mechanism, the bottle mouth is turned down, the sterile water is rinsed and drained, and it is automatically turned over to the bottle mouth facing up, and then transported to the filling through the star wheel and Installed. The main structure of the equipment is in contact with the flushing medium and the external protective cover is made of high-quality stainless steel, open type gear transmission.

Brand new stainless steel clamp, simple structure, convenient adjustment, less contact area with bottle mouth, effectively avoiding secondary pollution to bottle mouth.

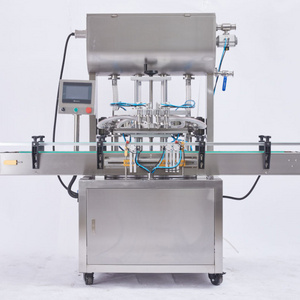

Filling Parts

The filling part realizes the filling of materials into the washed bottles sent by the bottle washer.

The filling valve adopts the pressure filling negative pressure type backflow method, the filling is quick and sensitive, and the filling level is high in accuracy. There is no spring in the valve, and the material does not contact with the spring, which facilitates the cleaning of the inside of the valve. In order to ensure the filling process and the filling temperature, the material in the filling valve is in a micro-reflux state when there is no bottle or when it is shut down. The filling cylinder adopts the full cylinder method to ensure the stability of the pressure in the cylinder.

The whole machine has a complete CIP cleaning interface.

The double guide rod bottle lifting structure is adopted to make the bottle lifting and centering stable.

The main drive adopts gear drive that is open type combined drive, which has high efficiency, low noise, long life, convenient maintenance and sufficient lubrication. The frequency converter is used to control the speed of the main motor of the machine. The machine adopts stepless frequency conversion speed regulation.

Capping Parts

The capping machine drives the turntable to rotate through the reducer. The cover leaves the hopper from the cover outlet under the action of centrifugal force.

There is a front and back cover separating device at the outlet. When the back cover passes by, the cover automatically falls into the return pipe, and the back cover is automatically blown into the hopper by wind.Only the front cover can enter the chute smoothly. The cover volume in the hopper is automatically detected by the photoelectric switch to control the cover conveyor to ensure that the lower cover achieves the desired effect. When the front cover enters the slideway, you can enter the cover feeding tray smoothly. In order to prevent accidents, an anti-reverse cover dial is also configured on the slideway to ensure that the cover that enters the feeding cover tray is correct.

A pair of slides are also provided photoelectric switch, when detecting that there is no cover, it will stop the host immediately.In order to effectively remove the broken cover without the anti-theft ring and clean the remaining cover of the hopper, there is a movable outlet directly opposite the hopper outlet to meet this function.

Control System

PLC automatically completes the whole process control of the three-in-one filling machine from bottle in to bottle out.

Using touch screen operation, production speed, shift output count, fault category, fault occurrence point, etc. are all displayed on the screen. It can also automatically count the time of occurrence of failures, failure categories and other information.

The main electrical components are all world famous brand products to ensure the excellent performance of the whole machine.

| Model |

ORGF-24 |

ORGF-32 |

ORGF-40 |

ORGF-60 |

ORGF-70 |

ORGF-80 |

| Capacity(500ml)(BPH) | 5000 | 8000-10000 | 10000-12000 | 12000-150000 | 15000-18000 | 18000-22000 |

| Power(KW) | 2.3 | 3 | 5.5 | 7.5 | 9.5 | 15 |

| Dimension(mm) | 2500*1760*2650 | 3100*2100*2650 | 3800*2800*2650 | 4000*3300*3400 | 4850*3650*3300 | 6500*5400*3500 |

| Weight(kg) | 3500 | 4650 | 6800 | 8500 | 10000 | 12500 |

| Applicable bottle range | H: 170-320mm D: 50-100mm | |||||

| Cleaning Pressure(Mpa) | 0.25-0.3 | |||||

Technical performance

1. This machine adopts fully automatic working mode, which automatically completes the station transfer of the bottle and the clarity and filling of each station without manual operation by personnel.

2. Equipped with a separate cleaning function, only cleaning but not filling, can be used as a pre-washing machine.

3. The mechanical transmission mechanism adopts the mechanical curved rod linkage mode to make the beer filling machine run smoothly, reliably, and accurately locate, and avoid the occurrence of failure rates.

4. The equipment is equipped with automatic flow detection, pressure detection, residual liquid detection after purging, wine spear opening detection and other detection functions, as well as station alarm.

5. The filling adopts CO2 backup pressure and pressure-maintained low-pressure differential fully enclosed filling method. The filling volume is detected by imported flowmeters, which can ensure low foam, low consumption and accurate filling volume of the canned wine.

6. The water tank is automatically filled with water, automatically heated and kept constant temperature

7. The equipment can set and adjust the filling capacity through the touch screen, and can adjust the error, and can display the number of bottles and liters filled in real time

Sherry

Luohe Orange Mechanical Equipment Co.,Ltd

Mobile/wechat/whatsapp:+8615939556928

Skype:sales02-orange; E: sales02(at)orangecoltd.com

Address: F5, Fortune PlazaSongshan Road, Luohe, Henan, China.