- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

400 KG

-

Power (kW):

-

15

-

Product Name:

-

Wood Pallet Notcher

-

Power:

-

15kw

-

Capacity:

-

600-800pics/h

-

Wood pallet length:

-

max 1800mm

-

Wood pallet width:

-

160mm

-

Slot depth:

-

<45mm

-

Slot width:

-

200-230mm

-

Material of knife:

-

Alloy

-

Dimension:

-

1200*1100*1200mm

-

Wight:

-

400KG

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

AG Mach

-

Machine Type:

-

other

-

Weight (KG):

-

400 KG

-

Power (kW):

-

15

-

Product Name:

-

Wood Pallet Notcher

-

Power:

-

15kw

-

Capacity:

-

600-800pics/h

-

Wood pallet length:

-

max 1800mm

-

Wood pallet width:

-

160mm

-

Slot depth:

-

<45mm

-

Slot width:

-

200-230mm

-

Material of knife:

-

Alloy

-

Dimension:

-

1200*1100*1200mm

-

Wight:

-

400KG

High Efficient Woodworking Equipment Single/Double Wood Pallet Notcher

Product Description

S

ingle/double head tray slotting machine is mainly used to make American standard wooden pallet . Forklifts are much easier to move.

1. Meet the international standard of wooden pallets, but also can be customized to your needs.

2. Can work continuously (feed and discharge), high production efficiency.

3. The operation process is simple and can be used by a single person .

4. The knife adopts hard alloy material, with high hardness, wear resistance, good strength and toughness, heat resistance, corrosion resistance and a series of excellent performance, so as to ensure the long term use of the machine performance.

Specification

|

Model

|

AG-KC-1

|

AG-KC-2

|

|

Power

|

15KW

|

30KW

|

|

Capacity

|

600-800pics/h

|

1800pics/h

|

|

Wood Pallet Length

|

Max 1800mm

|

Max 1400mm

|

|

Wood Pallet Width

|

160mm

|

Max 90mm

|

|

Slot Depth

|

<45mm

|

<45mm

|

|

Slot Width

|

200-230mm

|

200-230mm

|

|

Material of knife

|

Alloy

|

Alloy

|

|

Dimension

|

1200*1100*1200mm

|

2300*1300*1300mm

|

|

Weight

|

400kg

|

1000kg

|

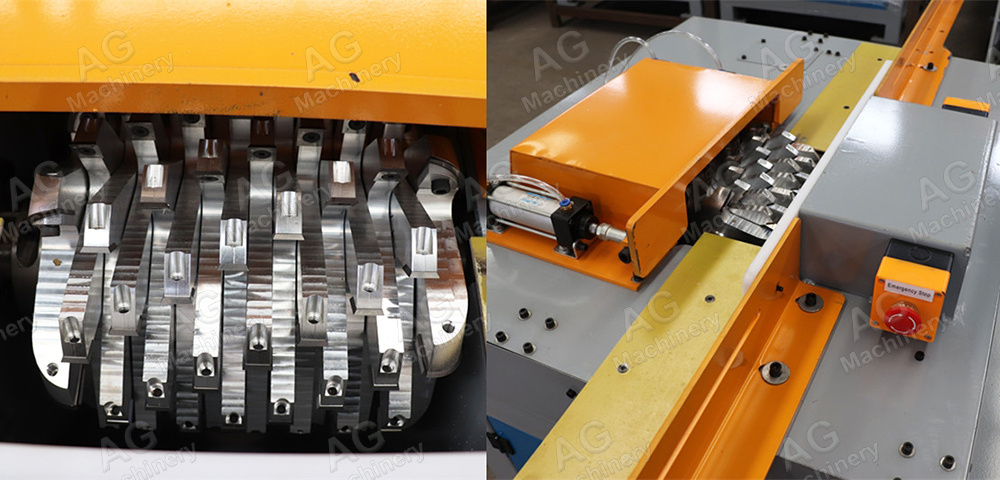

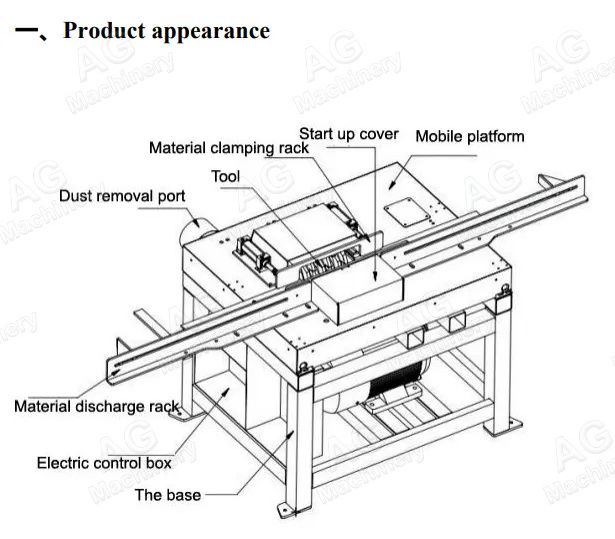

Details Images

Single Wood Pallet Notcher:

Apply for many kinds of slots, also can customized. pallet machine/pallet making machine/pallet manufacturing machine.

Blades are divided into semicircle knives and flat knives. Half round knife 2 pieces, each piece 6 teeth. Flat knife 14 pieces, each piece of 6 teeth. Continuous feeding and automatic discharging platform, standard size, high precision, the depth and width of the groove sizes can be adjusted.

Blades are divided into semicircle knives and flat knives. Half round knife 2 pieces, each piece 6 teeth. Flat knife 14 pieces, each piece of 6 teeth. Continuous feeding and automatic discharging platform, standard size, high precision, the depth and width of the groove sizes can be adjusted.

Double Wood Pallet Notcher:

Raw Material

Final Products:

Routine Maintenance

1. Check, adjust and lubricate the conveying device and transmission device regularly.

2. Regularly check whether the length and tightness of the main motor belt are moderate.

3. Regularly check whether there is sawing dust in the cylinder loop and clean it in time.

4. The tool should be cleaned regularly (3-5 days) with diesel, with a clean wiping machine cloth, clean the debris and wipe it with a cloth.

5. Check whether the spindle nut is loose regularly.

3. Regularly check whether there is sawing dust in the cylinder loop and clean it in time.

4. The tool should be cleaned regularly (3-5 days) with diesel, with a clean wiping machine cloth, clean the debris and wipe it with a cloth.

5. Check whether the spindle nut is loose regularly.

Related Equipment

Pallet Nailing Machine:

Pallet Dismantler:

Pallet Shredder:

Packing & Delivery

Installation and Handling

1.After receiving the equipment, if any serious damage is found, please contact the distributor or manufacturer in time.

4.During installation, the cutting tool and all accessories must be securely installed on the body, and all protection devices and safety devices should be installed in the corresponding positions. The machine can only be started when it is in a safe and normal state.

2.This machine is a small equipment, suitable for forklift or crane handling, handling please pay attention to keep the mechanical balance, handling process should be careful to avoid machine collision or tilt.

3.The machine must be placed on the solid concrete ground, mechanical workbench should be placed level.

4.During installation, the cutting tool and all accessories must be securely installed on the body, and all protection devices and safety devices should be installed in the corresponding positions. The machine can only be started when it is in a safe and normal state.

5.According to the machine electrical principle to connect the power supply, check whether the switch is normal, check whether the spindle rotation direction is correct.

Hot Searches