- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Tenjan

-

Name:

-

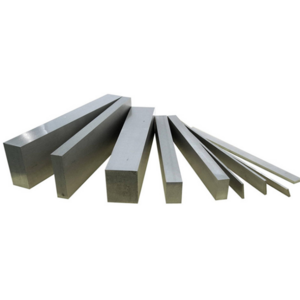

cold drawn steel bar

-

Material:

-

Q235/Q345/SS400/ST37-2/ST52/Q420/Q460/S235JR/S275JR/S355JR

-

Length:

-

1-12m

-

MOQ:

-

5 Tons

-

Packing:

-

Anti Rust Oil + Plastic bag

-

TRADE TERM:

-

FOB CIF CFR CNF EXWORK

-

Technology:

-

Cold Draw

Quick Details

-

Steel Grade:

-

cold drawn steel bar

-

Tolerance:

-

±0.1mm, ±1mm

-

Grade:

-

cold drawn steel bar

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Tenjan

-

Name:

-

cold drawn steel bar

-

Material:

-

Q235/Q345/SS400/ST37-2/ST52/Q420/Q460/S235JR/S275JR/S355JR

-

Length:

-

1-12m

-

MOQ:

-

5 Tons

-

Packing:

-

Anti Rust Oil + Plastic bag

-

TRADE TERM:

-

FOB CIF CFR CNF EXWORK

-

Technology:

-

Cold Draw

Free Cutting Steel Tube & Bar

|

Product Name

|

Free Cutting SteelTube(Cold Drawn/Cold Rolle d)

|

|

|

Free Cutting Steel Bar (Cold Drawn )

|

|

Material

|

1215、1213、1144、12L14、11SMn30(1.0715)、EN1A、A11、A12、Y15Y15Pb、SUM22、SUM23、$UM24L

|

|

Production Range

|

0D:10-85mm(0.39-3.35inch)

|

|

|

Wall Thickness: 2-13mm(0.079-0.52inch)

|

|

Shape

|

Round& Customized other shapes ( Hex and other spe cial shape according to the drawing )

|

|

Steel Grade

|

Standard

|

Chemical Composition

|

|

|

|

|

|

|

||||||

|

|

|

C

|

Si

|

Mn

|

S

|

P

|

Cu

|

Pb

|

||||||

|

1215

|

ASTM

|

max0.09

|

|

0.75-1.05

|

0.26-0.35

|

0.04-0.09

|

|

|

||||||

|

1213

|

ASTM

|

max0.13

|

|

0.7-1.0

|

0.24-0.33

|

0.07-0.12

|

|

|

||||||

|

1144

|

ASTM

|

0.4-0.48

|

|

1.35-1.65

|

0.24-0.33

|

max0.04

|

|

|

||||||

|

12L14

|

ASTM

|

max0.5

|

|

0.85-1.15

|

0.26-0.35

|

0.04-0.09

|

|

0.15-0.35

|

||||||

|

11SMn30/1.0715

|

EN10087

|

max0.14

|

max0.5

|

0.9-1.3

|

0.27-0.33

|

max0.11

|

|

|

||||||

|

EN1A

|

BS970

|

0.07-0.15

|

max0.1

|

0.8-1.2

|

0.2-0.3

|

max0.07

|

|

|

||||||

|

A11

|

GOST 1414-75

|

0.07-0.15

|

max0.1

|

0.8-1.2

|

0.15-0.25

|

0.06-0.12

|

max0.25

|

|

||||||

|

A12

|

GOST 1414-75

|

0.08-0.16

|

0.15-0.35

|

0.7-1.1

|

0.08-0.2

|

0.08-0.15

|

max0.25

|

|

||||||

|

Y15

|

GB/T 8731

|

0.1-0.18

|

max0.15

|

0.8-1.2

|

0.23-0.33

|

0.05-0.1

|

|

|

||||||

|

Y15Pb

|

GB/T 8731

|

max0.5

|

|

0.85-1.15

|

0.26-0.35

|

max0.11

|

|

0.15-0.35

|

||||||

|

SUM22

|

JIS G 4804

|

max0.13

|

|

0.7-1.0

|

0.24-0.33

|

0.07-0.12

|

|

|

||||||

|

SUM23

|

JIS G 4804

|

0.75-1.05

|

|

0.75-1.05

|

0.26-0.35

|

0.04-0.09

|

|

|

||||||

|

SUM24L

|

JIS G 4804

|

max0.5

|

|

0.85-1.15

|

0.26-0.35

|

0.04-0.09

|

|

0.15-0.35

|

||||||

Product Advantages

Free cutting steel: environmental protection material, high sulfur, improved cutting performance, suitable for automated production.

Free Cutting Steel Tube(Cold Drawn/Cold Rolled),Free Cutting Steel Bar(Round&Other Shapes can be customized),Free Cutting Steel Tube (different sizes).

Used in various fields such as auto parts, agricultural machinery parts, engineering machinery, machining, transmission, hardware tools, home appliances, fasteners, hydraulic joint, etc.

Production Process

Tenjan has a full-process production line.

Delivery time and quality can be guaranteed.

Inspection Process- Quality Assurance

Standard Export Packaging, Suitable For Sea Transportation.

Hot Products

About Us

Changzhou Tenjan Steel Tube Co., Ltd., established in 2004, is a technology-based manufacturer integrating seamless steel tube design, R&D, and production. Tenjan has an annual production capacity of more than 60,000 tons. Chairman "Wensheng Gu ", adhering to "one life one thing", has been focusing on R&D of seamless steel tube for more than 30 years.

·Tenjan, fills the technology gap in both domestic and foreign markets

Tenjan has produced free cutting steel tube successfully through R&D, which fills the technology gap in both domestic and foreign

markets.

·High-Precision customized machine, help customer improve production efficiency

Self-customized high-precision straightening machine has reached the domestic leading level. It effectively helps customers to

improve the post-processing efficiency, reduce malfunction of

equipment, and increase equipment lifespan.

·UT&NDT equipment, quality can be guaranteed before EX-FTY

Ultrasonic & eddy current flaw detection integrated machine, detects defects on the inner and outer surfaces of steel tubes and its

accuracy can reach 0.02mm.

FAQ

1.Q: What is the Minimum Order Quantity?

A:

5 tons/size.

2.Q: What are the Payment Terms?

A:

L/C or T/T, 30% deposit, 70% balance against copy of BL.

3.Q: How long is the Delivery Time?

A: 30-50 days.

Starting from production around 30 days, which including perforation, cycling

pickling, cycling annealing, squeezing head, cold rolling, cold drawing, straightening,

ultrasonic & eddy current flaw detection, cutting head&tail, tensile test and finished product inspection.

4.Q:Warranty of Rebar Coupler?

A:

Any quality issues that do not comply with the contract before use of 1215 steel tubes, we accept the return of the refund.

Hot Searches