- Product Details

- {{item.text}}

Quick Details

-

Production Capacity:

-

100sets/month

-

Power:

-

2000

-

Dimension(L*W*H):

-

960*1230*2000mm

-

Product name:

-

CGMA 3 tools PVC window corner cleaning machine

-

Air souece:

-

0.6-0.8MPa

-

Air consumption:

-

100L/min

-

Size of Cycle milling tool:

-

D230*30*24T

-

Profile height:

-

30-120mm

-

Profile width:

-

30-110mm

Quick Details

-

Brand Name:

-

CGMA

-

Voltage:

-

380V 50Hz

-

Weight:

-

580 kg

-

Production Capacity:

-

100sets/month

-

Power:

-

2000

-

Dimension(L*W*H):

-

960*1230*2000mm

-

Product name:

-

CGMA 3 tools PVC window corner cleaning machine

-

Air souece:

-

0.6-0.8MPa

-

Air consumption:

-

100L/min

-

Size of Cycle milling tool:

-

D230*30*24T

-

Profile height:

-

30-120mm

-

Profile width:

-

30-110mm

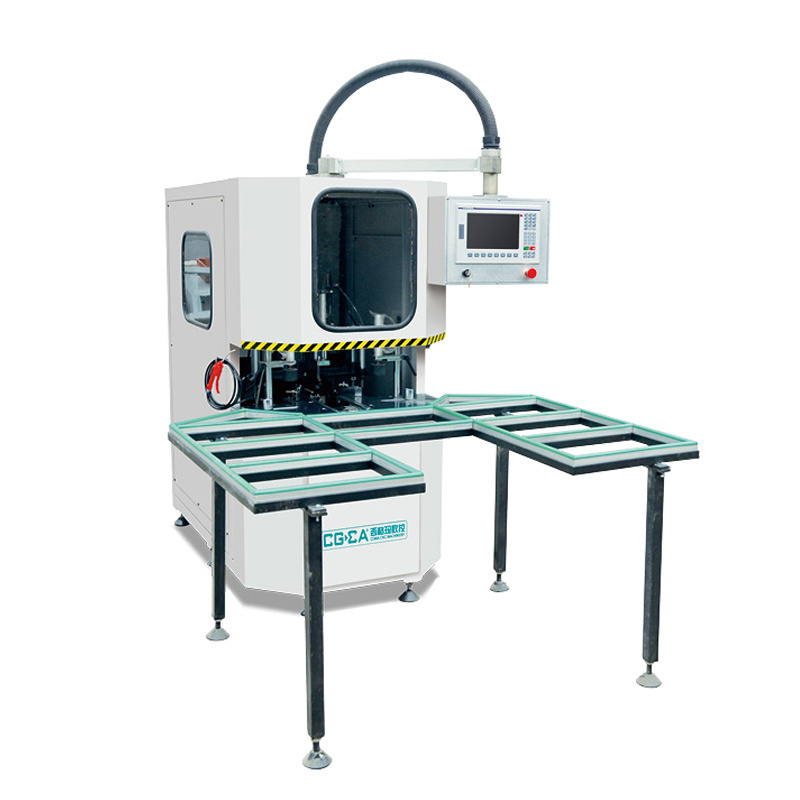

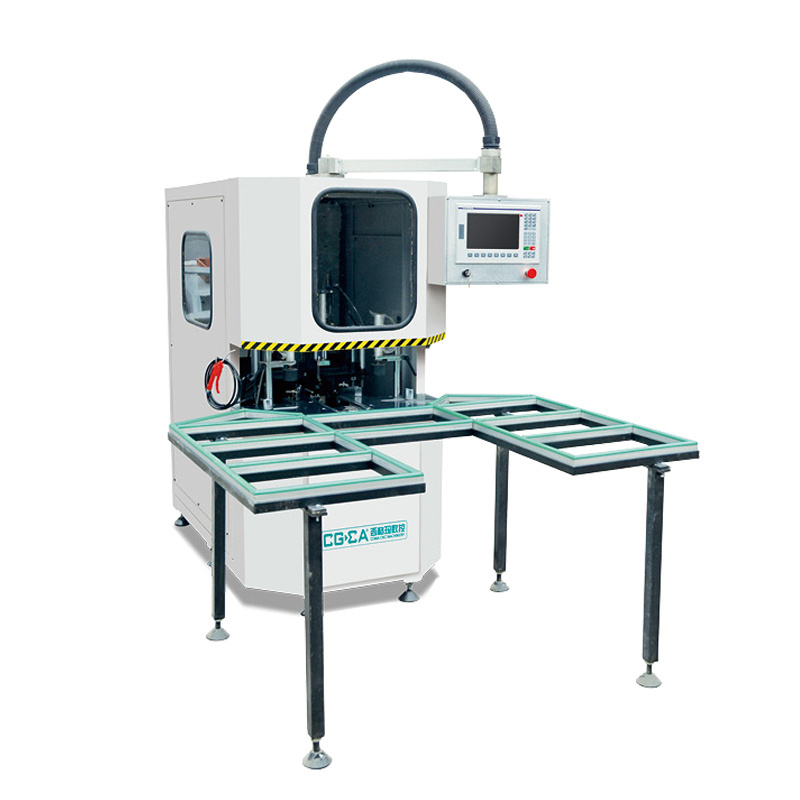

CGMA 3 Tools Corner Cleaning Mchine for PVC Window and Door

Machine Feature:

1. The machine is a two axis three blade structure, used for cleaning 90 ° external corners of PVC door and window frames and profiles, as well as welding burrs on the upper and lower parts of the profiles;

2. It has functions of sawing, milling, and broaching;

3. Adopting a servo control system with high precision in repeated positioning;

4. Graphical user interface, with intuitive display of tool running trajectory;

5. Equipped with a USB interface, it can store processing programs for various specifications of profiles through external storage tools, and the system can also be regularly upgraded through external storage tools;

6. Teaching programming function, simple and intuitive programming, with the ability to set two-dimensional machining programs through CNC programming;

7. It can achieve arc difference compensation and diagonal difference compensation, which can meet the needs of producing high-quality doors and windows for various cross-sectional profiles.

|

Parameter

|

Description

|

|

Power supply

|

AC 380V/50Hz

|

|

Air source

|

0.6-0.8MPa

|

|

Air consumption

|

100L/min

|

|

Total power

|

2KW

|

|

Size of Milling Cutter

|

D230*30*2T

|

|

Profile Height

|

30-120mm

|

|

Profile Width

|

30-110mm

|

We Provide Professional Digital Factory Solutions.

Hot Searches