- Product Details

- {{item.text}}

Quick Details

-

Power:

-

15-25KW

-

Dimension(L*W*H):

-

2300*2000*2200mm

-

Weight:

-

400 KG

-

Material:

-

Stainless Steel 304

-

Function:

-

Brewing Beer Brewing Equipment

-

Insulation:

-

Polyurethane/rockwool 80mm

-

Control system:

-

PIC Control

-

Thickness:

-

2-3mm / Inside:3.0mm Outside:2mm

-

Keywords:

-

Brewpub Beer Equipment

-

Cooling way:

-

Dimple Plate Cooling

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

CASSMAN

-

Voltage:

-

220,380, customized

-

Power:

-

15-25KW

-

Dimension(L*W*H):

-

2300*2000*2200mm

-

Weight:

-

400 KG

-

Material:

-

Stainless Steel 304

-

Function:

-

Brewing Beer Brewing Equipment

-

Insulation:

-

Polyurethane/rockwool 80mm

-

Control system:

-

PIC Control

-

Thickness:

-

2-3mm / Inside:3.0mm Outside:2mm

-

Keywords:

-

Brewpub Beer Equipment

-

Cooling way:

-

Dimple Plate Cooling

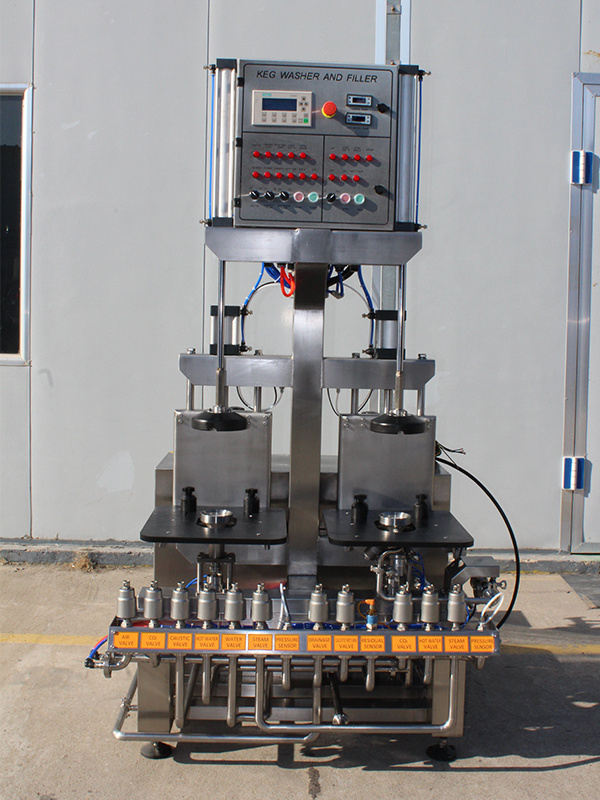

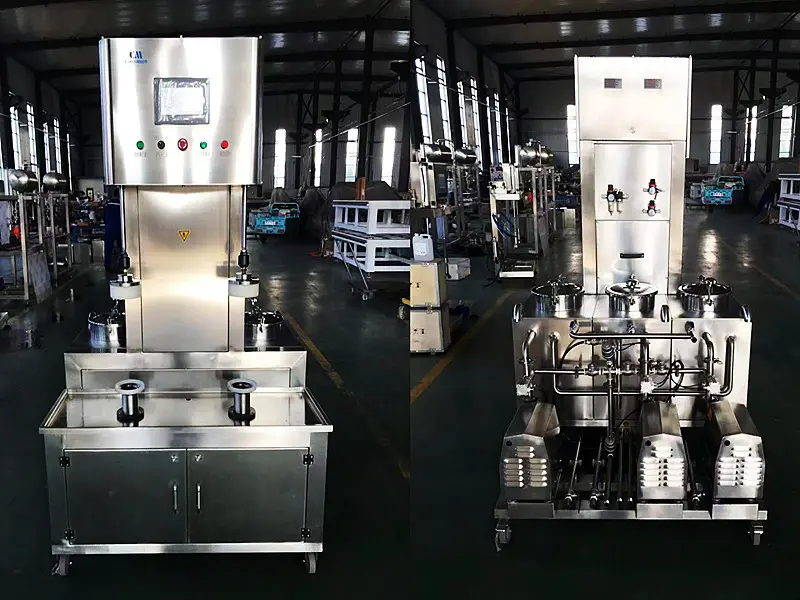

Semi-auto beer keg filling machine keg filler equipment

Main Technical Parameters

|

1550*850*2200mm |

|

|

Net Weight |

300KG |

|

Production Capacity |

200 bottles/Hr |

|

1Applicable Bottles |

Customized |

|

Working Stations |

4 filling heads+4 capping heads |

|

Power Supply Voltage |

Customized |

Main function and feature

1,Automatic control by PLC, all parameters can be adjusted.

2,Filling and capping process can be finished in this machine at one time.

3,With CO2 purge and pressurization and function.

4,Adopt isobar filling method and with unique pressure maintaining system,performance stable and reliable, beer loss minimum.

5,With pressure compensator, to guarantee a stable filling process.

Working process

Fix the bottles--CO2 Purge-- CO2 pressurizing--CO2 Purge-- CO2 pressurizing -- filling -- pressure stabilization -- pressure relief--stop--move the bottles to the capping stations--capping--take the bottles

Warranty:

Equipment warranty includes tank warranty, electric parts warranty, auxiliary parts warranty, etc. .

1, Cassman provides 3-5 years warranty for the main tank, 1 year warranty for electrical components and auxiliary parts, etc., and lifetime after-sales service.

2, In order to ensure the normal operation of the brewery, we can provide a separate set of spare parts according to the customer's request, customers can replace parts in case of abrasion damage.

Maintenance:

During operation, daily maintenance for the equipment is important. Cassman will provide maintenance guide., if need, we can send engineer to customer's site for repair and maintenance.

Beer equipment model selection:

1, Based on years of experience, Cassman can provide standard models of beer brewing equipment. We have mature experience in brewing technology and equipment design.

2, Cassman can provide custom-made service as per customer's requirement. including customize brewhouse system, fermentation tank, brite beer tank, coffee equipment, whiskey distillation equipment, stainless steel tank, etc.

Brewery design:

Cassman can help to design layout for newly built brewery, and we will supply P&ID drawings, electrical connection diagrams,flow chart, tank drawings, etc. , 3D drawings are also available if needs.

Installation:

Cassman has 6 to 8 experienced technical engineers, we can provide on-site installation and debugging instruction as per customer's needs.

1, To ensure good after-sales service, we will appoint the same technical personnel to debug and load the equipment before delivery,

2, For single tank, if on-site installation service is unnecassary, Cassman will provide equipment drawings and installation guides so that customers can install by themselves.

1:All material are SUS 304 or SUS 316.

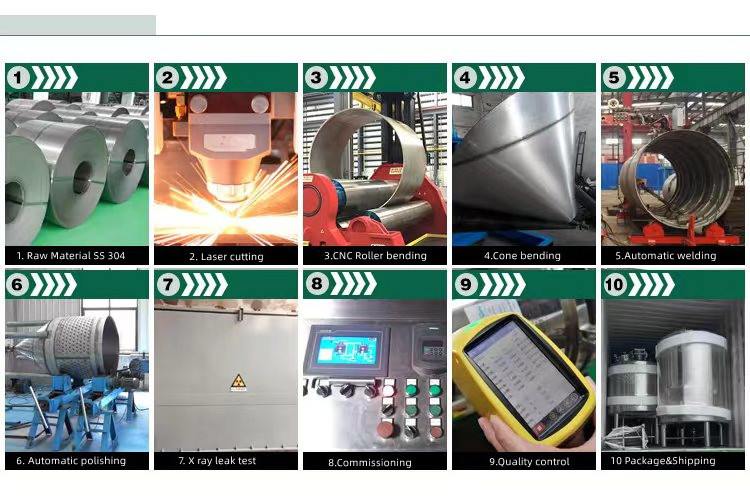

2:Cassman company equipped with large-scale automatic tools such as laser cutting machines, automatic welding machines, automatic polishing machines, and inspection rooms, ensuring flawless processing details of the equipment.

3:All equipment is tested and debugged before shipment, ensuring that a complete set of perfect solutions arrive at the customer's hands.

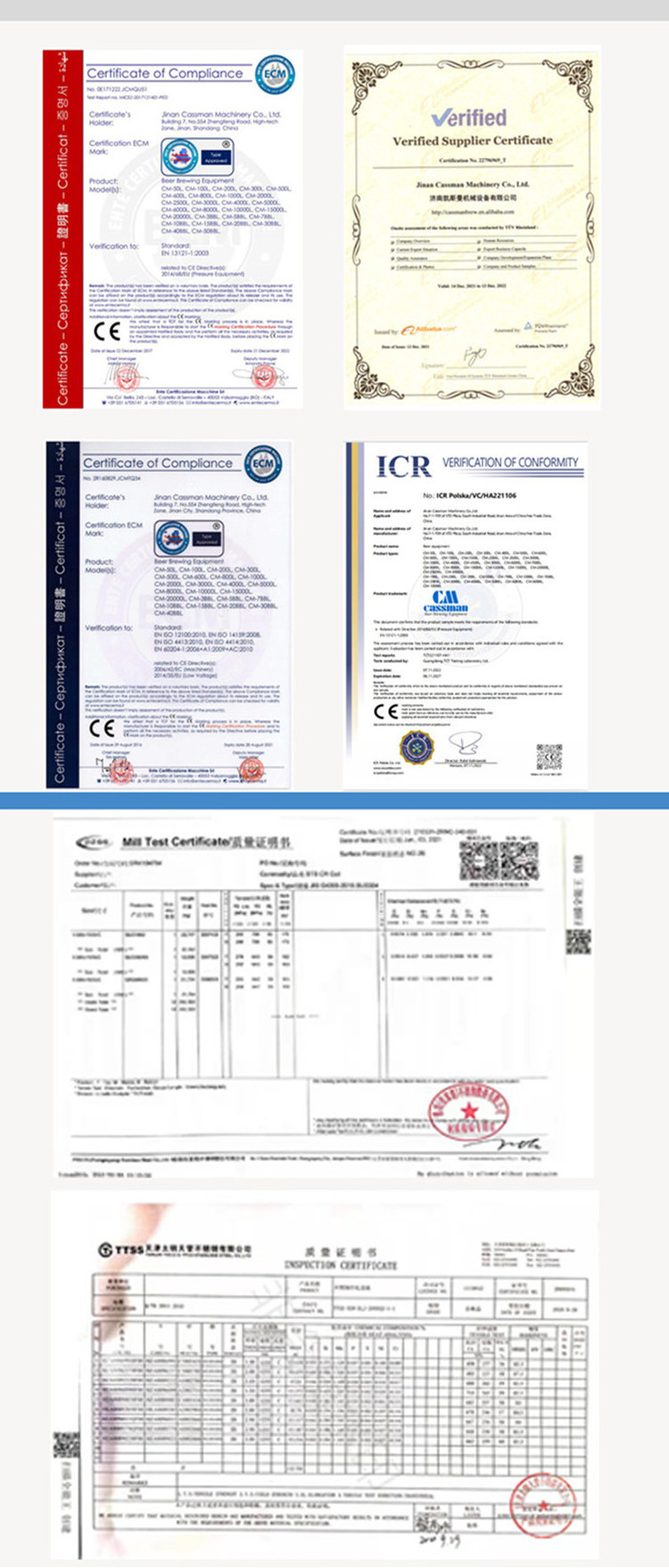

CE: Certification of Compliance

PED(TUV): Certification of Compliance, Certification of Conformity

SGS: Gold Plus Supplier Assessment Certificate

Material certification of the SUS 304, 316.