- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

1745*2000*3059

-

Motor Power (kW):

-

11*4kW*P

-

Model Number:

-

STC-110V

-

Weight (T):

-

14.2

-

Marketing Type:

-

Hot Product 2023

-

Machine name:

-

110ton pneumatic press machine

-

Punching capacity:

-

110ton for pneumatic press machine

-

Slider strokes per minute:

-

35-65 SPM for machine press

-

Punch weight:

-

14.2 tons for punch press

-

Long slider length:

-

180 mm for stamping machine

-

Maximum mode height:

-

400 mm for hole punching machine

-

Material:

-

42CrMo used for Crankshaft, ZQSn10-1 used for Copper sets

-

Color:

-

Customer Request

-

After Warranty Service:

-

Video technical support, Online support, Spare parts

-

Slider guide position stucture::

-

2 corner 6 guide structure

Quick Details

-

Slide Stroke (mm):

-

180mm

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

QIAOSEN

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

1745*2000*3059

-

Motor Power (kW):

-

11*4kW*P

-

Model Number:

-

STC-110V

-

Weight (T):

-

14.2

-

Marketing Type:

-

Hot Product 2023

-

Machine name:

-

110ton pneumatic press machine

-

Punching capacity:

-

110ton for pneumatic press machine

-

Slider strokes per minute:

-

35-65 SPM for machine press

-

Punch weight:

-

14.2 tons for punch press

-

Long slider length:

-

180 mm for stamping machine

-

Maximum mode height:

-

400 mm for hole punching machine

-

Material:

-

42CrMo used for Crankshaft, ZQSn10-1 used for Copper sets

-

Color:

-

Customer Request

-

After Warranty Service:

-

Video technical support, Online support, Spare parts

-

Slider guide position stucture::

-

2 corner 6 guide structure

Product Specifications

|

NO

|

Item

|

Unit

|

STC-110V

|

STC-110H

|

|

|

1

|

Punching capacity

|

ton

|

110

|

|

|

|

2

|

Ability occurrence point

|

mm

|

5

|

3

|

|

|

3

|

Slider strokes per minute

|

SPM

|

35-65

|

50-100

|

|

|

4

|

Long slider length

|

mm

|

180

|

110

|

|

|

5

|

Maximum mode height

|

mm

|

400

|

435

|

|

|

6

|

Slider adjustment amount

|

mm

|

100

|

|

|

|

7

|

Up platform area

|

mm

|

1400*500*70

|

|

|

|

8

|

Down platform area

|

mm

|

1800*650*130

|

|

|

|

9

|

Slider center to machine distance

|

mm

|

-

|

|

|

|

10

|

Platform to floor distance

|

mm

|

830

|

|

|

|

11

|

Shank hole

|

mm

|

-

|

|

|

|

12

|

Main motor power

|

kw*p

|

11*4

|

|

|

|

13

|

Air presure

|

kg/cm^2

|

5

|

|

|

|

14

|

Punch accuracy grade

|

|

JIS 1

|

|

|

|

15

|

Punch dimension(L*W*H)

|

mm

|

1745*2000*3059

|

|

|

|

16

|

Punch weight

|

ton

|

14.2

|

|

|

|

17

|

Die cushion capacity(optional)

|

ton

|

-

|

|

|

|

18

|

Stroke(optional)

|

mm

|

-

|

|

|

|

19

|

Active area(optional)

|

mm

|

-

|

|

|

Product Overview

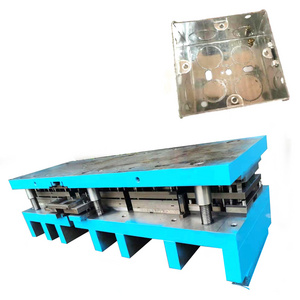

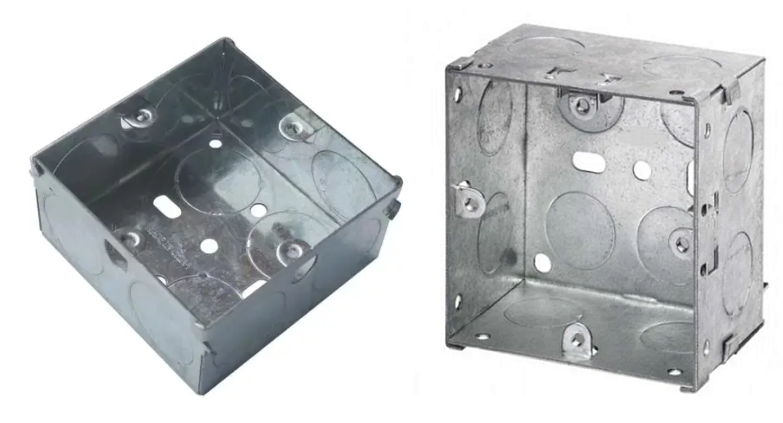

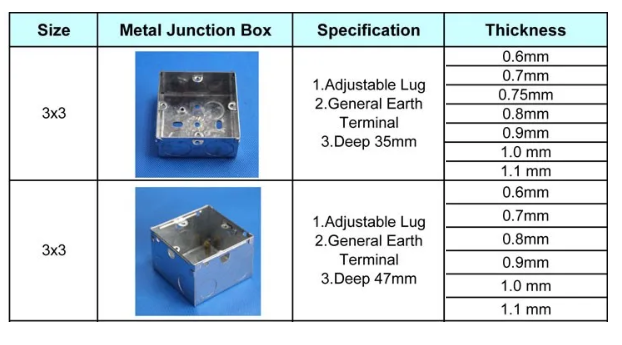

3*3inch 47mm Deep Switch Box Junction Box Electrical Metal Box

Automatic Electric Metal Junction Electrical Switch Box Making Machine Metal Press Punching Machine

Product Application

This punching press machine is used for stamping sheet metal parts . It can be cooperated with automatic feeding machine and stamping molds to form the automatic production line. It is suitable for blanking, trimming, punching hole, forming, bending, shallow stretching and other cold stamping process. The machine used for different kinds of materials, including metal, copper, aluminum, brass, alloy, steel, iron etc.

●JIS1 Precision

The high-strength fuselage structure has small deformation and JIS 1 class precision inspection standard.

●Easy Operation and Easy Maintenance

The body of C-type punching machine is open on 3-sides, easy to operate, easy to install molds,

feeders, and automatic mold changing devices to realize automatic production, and the price is economical and affordable. OMPI pneumatic dry clutch are used,which is very easy maintenance.

●Energy Efficient

Energy and cost saving, can improve the material use rate to 105%-108%, Save 25%-35% of energy , which means can save 4004 kw.h per year for one machine.

●Manual/Semi-Automation/Full Automation

Considering different product processes, manual mode, semi-automatic mode and fully automatic mode are all optional.

Full automation, can upload all mold information to one machine in one time, then copy to other

machines, and we use Siemens system.

●Safety

Equipped with photo-electric device on the down platform side , machine will stop when block the grating.Also have oil pressure overload device, machine will stop when weight overload; Whats more, there have 2 emergency buttons on the machine, can react very fast when there have something wrong with machine.

●Stable

Stable using, slider adopt high frequency quenching and rail grinding process, which have small wear, high precision and improve mold life.

The body of C-type punching machine is open on 3-sides, easy to operate, easy to install molds,

feeders, and automatic mold changing devices to realize automatic production, and the price is economical and affordable. OMPI pneumatic dry clutch are used,which is very easy maintenance.

●Energy Efficient

Energy and cost saving, can improve the material use rate to 105%-108%, Save 25%-35% of energy , which means can save 4004 kw.h per year for one machine.

●Manual/Semi-Automation/Full Automation

Considering different product processes, manual mode, semi-automatic mode and fully automatic mode are all optional.

Full automation, can upload all mold information to one machine in one time, then copy to other

machines, and we use Siemens system.

●Safety

Equipped with photo-electric device on the down platform side , machine will stop when block the grating.Also have oil pressure overload device, machine will stop when weight overload; Whats more, there have 2 emergency buttons on the machine, can react very fast when there have something wrong with machine.

●Stable

Stable using, slider adopt high frequency quenching and rail grinding process, which have small wear, high precision and improve mold life.

Related Products

Hot Searches