Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Granules Production

-

Inverter:

-

ABB Frequency Controller

-

Motor:

-

SIEMENS Brand

-

Raw material:

-

PP Waste Plastic Bag

-

Machine:

-

PP PE Pelletizer Line

-

Machine Type:

-

Double Stage Pelletizing

-

Color:

-

Customer Choice

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Name:

-

Plastic Recycling Granulator Machine

-

Keywords:

-

Pp Pe Plastic Granulating Machine

-

Application:

-

Granules Production

-

Inverter:

-

ABB Frequency Controller

-

Motor:

-

SIEMENS Brand

-

Raw material:

-

PP Waste Plastic Bag

-

Machine:

-

PP PE Pelletizer Line

-

Machine Type:

-

Double Stage Pelletizing

-

Color:

-

Customer Choice

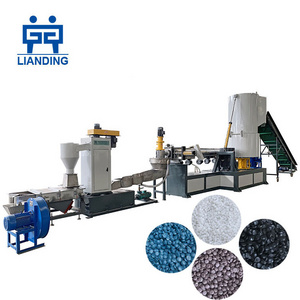

Product Application

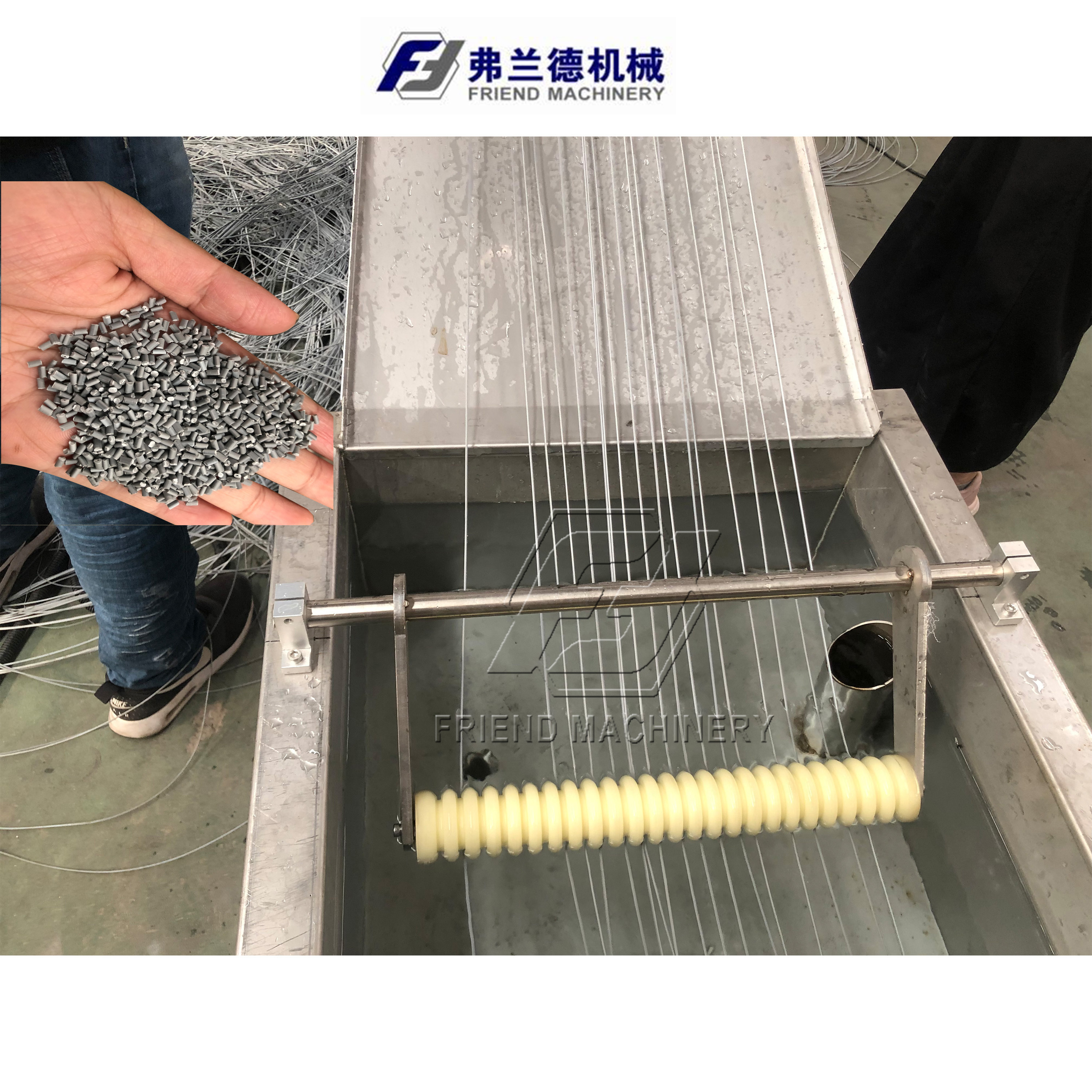

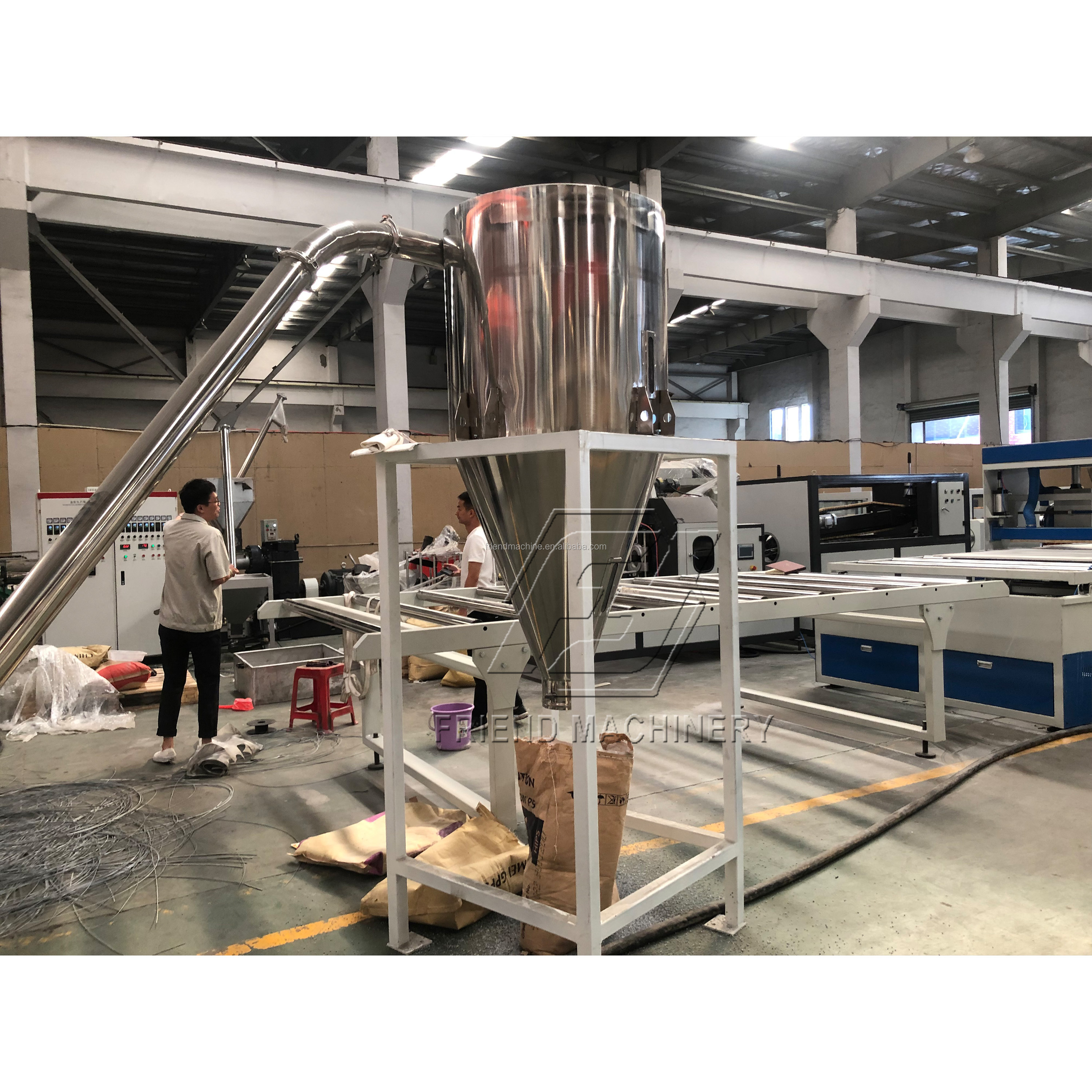

In order to recycle waste plastics, waste plastic need to be washed, dried then melted, plasticized, extruded into strips, cooled by cooling system, and cut into granules by granulator. These granules are further processed into various plastics products by blowing, injection and calendering.

Main Features

1) Single stage extruder and double stage extruders can be used according to user's requirement or material condition.

2) Plastic pelletized polyethylene (PE), polypropylene (PP), polystyrene (PS), polyvinyl chloride (pvc), PET, HDPE, ABS and other engineering plastics or general plastics recycling and granulation.

3) Granules cutting type: water ring face cutting, strip/noodle type cutting and hot cutting;

4) Waste woven bags and waste film can be directly put into the granulation line without crushing.

5) The main engine is equipped with full automatic control cabinet and PLC operating system. It is easy to operate and has stable performance.

6) Low energy consumption, remarkable energy saving effect, high output, mechatronics. Plastic granulation

Main Parameter

|

Model |

Screw dia(mm) |

L/D |

Screw speed(rpm) |

Power of main motor(kw) |

Output(kg/h) |

|

GWP90 |

90 |

33:1 |

20-150 |

75-90 |

200-300 |

|

GWP120 |

120 |

33:1 |

20-150 |

110-132 |

300-400 |

|

GWP150 |

150 |

33:1 |

20-150 |

160-200 |

400-500 |

|

GWP180 |

180 |

33:1 |

20-150 |

250-315 |

600-800 |

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Provide on-site installation instructions

* Responsible for on-site commissioning of equipment (users provide room and board for commissioning personnel)

* Responsible for pre-employment operation and maintenance training for the demand side personnel

* Long-term guarantee of spare parts supply

*Long-term technical advisory services.