- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Lithium Battery Raw Material

-

Width:

-

200mm

-

Grade:

-

Copper Foil

-

Model Number:

-

LITH-Cu-08

-

Brand Name:

-

Lith

-

Place of Origin:

-

Fujian, China

-

Purity:

-

99.9%

-

Length:

-

100m

-

Roller core inner diameter:

-

76mm

-

Cu:

-

≥99.9%

-

Areal density (g/m2):

-

85-90

Quick Details

-

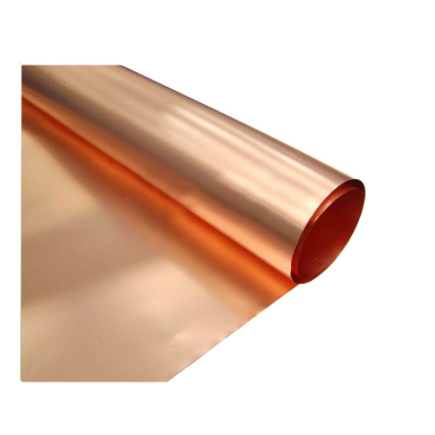

Material:

-

Copper

-

Cu (Min):

-

Customizable

-

Alloy Or Not:

-

Non-Alloy

-

Application:

-

Lithium Battery Raw Material

-

Width:

-

200mm

-

Grade:

-

Copper Foil

-

Model Number:

-

LITH-Cu-08

-

Brand Name:

-

Lith

-

Place of Origin:

-

Fujian, China

-

Purity:

-

99.9%

-

Length:

-

100m

-

Roller core inner diameter:

-

76mm

-

Cu:

-

≥99.9%

-

Areal density (g/m2):

-

85-90

9um-15um Copper Foil Cu Foil for Lithium Battery Raw Material Li-Ion Cell Anode Material

Features

|

NO |

Items |

Criteria |

Remarks |

|

|

1 |

Vibration test |

The battery is to be tested in three mutually perpendicular to each axis. |

No fire, no explosion |

|

|

2 |

Drop Test |

Drop the battery from 1m height onto 5cm it 3 times each of X, Y, and Z directions at 25±2°C |

||

|

3 |

Short circuiting Test |

After standard charge,the battery shall be subjected to a short-circuit condition with a wire of resistance less than 100(o) |

||

|

4 |

High temperature test |

Leaving the battery at 85°C for 4hours after standard charge |

No fire, no explosion Capacity≥80%C5 |

|

|

5 |

Heating Test |

The temperature of the oven is to be raised at a rate of 5±2°C/min to a temperature of 130±2°C for 30 minutes. |

No explosion, no fire |

|

|

6 |

Overcharge testing (NO PCM) |

3C 4.6V. |

||

|

7 |

Storage Characteristics 1 |

standard charge and then storage at 25±2°C for 30 days. |

Remaining Capacity≥85% |

|

|

8 |

Storage Characteristics 2 |

1 |

after standard charge and then storage at 60±2°C for 7 days. |

Remaining Capacity≥60% |

|

2 |

the capacity on standard discharge shall be measured after standard charge. |

Recovery capacity≥80% |

||

Specifications

|

Item |

L-Cu-09 |

L-Cu-10 |

L-Cu-12 |

|

|

Width (mm) |

customized |

|||

|

Thickness (um) |

9 |

10 |

12 |

|

|

Areal density (g/m2) |

85-90 |

95-100 |

105-110 |

|

|

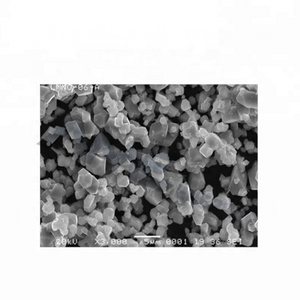

Purity(%) More than 99.9% |

Cu ≥99.9% |

|||

|

Fe < 0.0010% |

||||

|

Bi < 0.00020% |

||||

|

Pb < 0.0005% |

||||

|

Roller core inner diameter |

76mm |

|||

|

Width |

200mm |

|||

|

Tensile strength (MPa) |

≥294 |

≥300 |

≥305 |

|

|

Normal elongation(%) |

2.5 |

2.7 |

3.0 |

|

|

High temperature Tensile strength180℃(MPa) |

≥147 |

≥150 |

≥153 |

|

|

High temperature elongation180℃(%) |

2 |

2 |

2.5 |

|

|

Anti oxidization(180℃ Heating 1h) |

No oxidation of points on the surface,The color does not change,Copper foil without fracture |

|||

|

Surface roughness(um)Rz |

Drum side(um) |

Less than 0.3 |

Less than 0.3 |

Less than 0.35 |

|

Matte side(um) |

Less than 3.0 |

Less than 3.5 |

Less than 4.0 |

|

|

Surface tension(dyne/cm) |

Drum side |

62 |

65 |

68 |

|

Matte side |

62 |

65 |

68 |

|

|

Coating performance |

Cu foil with uniform tension on both sides, slurry coating uniformity |

|||