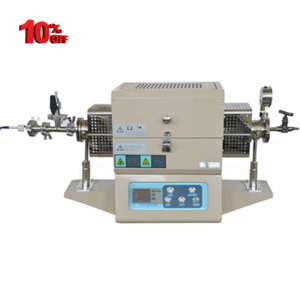

- Product Details

- {{item.text}}

Quick Details

-

Core Components:

-

temperature controller

-

Brand Name:

-

Saftherm

-

Year:

-

2023

-

Voltage:

-

Customized

-

Dimension(L*W*H):

-

Customized

-

Weight (T):

-

1 T

-

Power (kW):

-

18/21/30/45/80/Customized

-

Product Name:

-

STT-2160-14

-

Max Temperature:

-

1400C

-

Continue Operating Temp.:

-

1300C

-

Heating Element:

-

Quality SIC Rod

-

Temperature Precision:

-

±1℃

-

Thermocouple:

-

S type

-

Temperature control:

-

30 Segments Programable

-

Heating Rate:

-

≤ 25℃/min ( suggest 15℃/min for longer life using of furnace )

-

Certification:

-

ISO9001 CE SGS

Quick Details

-

Place of Origin:

-

Henan, China

-

Marketing Type:

-

New Product 2023

-

Warranty of core components:

-

3 Year

-

Core Components:

-

temperature controller

-

Brand Name:

-

Saftherm

-

Year:

-

2023

-

Voltage:

-

Customized

-

Dimension(L*W*H):

-

Customized

-

Weight (T):

-

1 T

-

Power (kW):

-

18/21/30/45/80/Customized

-

Product Name:

-

STT-2160-14

-

Max Temperature:

-

1400C

-

Continue Operating Temp.:

-

1300C

-

Heating Element:

-

Quality SIC Rod

-

Temperature Precision:

-

±1℃

-

Thermocouple:

-

S type

-

Temperature control:

-

30 Segments Programable

-

Heating Rate:

-

≤ 25℃/min ( suggest 15℃/min for longer life using of furnace )

-

Certification:

-

ISO9001 CE SGS

Product Application

The trolley-type sintering furnace is mainly developed for the sintering of large-scale materials or small-scale production

applications. High-quality furnace materials and new construction technology for large-capacity furnaces, stable temperature

control and intelligent walking trolley system can ensure the reliable quality of sintered products. It is used in the fields of

new materials such as metal materials, ceramic materials, nanomaterials, and semiconductor materials.

|

Model

|

Chmaber size(mm)

|

volume

|

Max temp.

|

Working temp.

|

voltage

|

power

|

Heating element

|

Temp precision

|

|

STT-96-12

|

400×600×400

|

96L

|

1200℃

|

1100℃

|

380V

|

18KW

|

HRE

|

±1℃

|

|

STT-288-12

|

600×800×600

|

288L

|

1200℃

|

1100℃

|

380V

|

30KW

|

HRE

|

±1℃

|

|

STT-640-12

|

800×1000×800

|

640L

|

1200℃

|

1100℃

|

380V

|

45KW

|

HRE

|

±1℃

|

|

STT-1200-12

|

1000×1200×1000

|

1200L

|

1200℃

|

1100℃

|

380V

|

80KW

|

HRE

|

±1℃

|

|

STT-2160-12

|

1200×1500×1200

|

2160L

|

1200℃

|

1100℃

|

380V

|

150KW

|

HRE

|

±1℃

|

|

STT-96-14

|

400×600×400

|

96L

|

1400℃

|

1300℃

|

380V

|

21KW

|

SIC

|

±1℃

|

|

STT-288-14

|

600×800×600

|

288L

|

1400℃

|

1300℃

|

380V

|

30KW

|

SIC

|

±1℃

|

|

STT-640-14

|

800×1000×800

|

640L

|

1400℃

|

1300℃

|

380V

|

50KW

|

SIC

|

±1℃

|

|

STT-1200-14

|

1000×1200×1000

|

1200L

|

1400℃

|

1300℃

|

380V

|

100KW

|

SIC

|

±1℃

|

|

STT-2160-14

|

1200×1500×1200

|

2160L

|

1400℃

|

1300℃

|

380V

|

200KW

|

SIC

|

±1℃

|

|

STT-96-17

|

400×600×400

|

96L

|

1700℃

|

1600℃

|

380V

|

25KW

|

MoSi2

|

±1℃

|

|

STT-288-17

|

600×800×600

|

288L

|

1700℃

|

1600℃

|

380V

|

50KW

|

MoSi2

|

±1℃

|

|

STT-640-17

|

800×1000×800

|

640L

|

1700℃

|

1600℃

|

380V

|

80KW

|

MoSi2

|

±1℃

|

|

STT-1200-17

|

1000×1200×1000

|

1200L

|

1700℃

|

1600℃

|

380V

|

150KW

|

MoSi2

|

±1℃

|

|

STT-2160-17

|

1200×1500×1200

|

2160L

|

1700℃

|

1600℃

|

380V

|

300kw

|

MoSi2

|

±1℃

|

Features

1. Multi-layer heat insulation design of refractory materials, multi-layer lightweight refractory brick lining or ceramic fiber

lining with strong structure, high-strength stacking and splicing, no asbestos components, small heat loss and low energy consumption.

2. Heating on three sides (left, right and bottom side) to achieve good uniformity in the furnace.

3. The silicon carbide bottom plate covers and protects the bottom of the furnace, which has high mechanical strength, good thermal conductivity, and provides horizontal load bearing.

4. The trolley at the bottom moves smoothly and without impact.

5. The material is loaded from bottom, and the workbench can be moved.

6. Can be customized according to process requirements.

7. Advanced control and adjustment system, precise temperature control.

8. There is an automatic flip-type exhaust port on the top of the furnace to realize the debinding of materials.

9. The furnace top circulation fan is selected to increase the uniformity of the temperature field in the furnace.

10. Furnace temperature and air rapid cooling control unit can be selected to realize rapid cooling within the furnace

temperature of 400°C.

11. Optional manual and automatic air intake control unit.

lining with strong structure, high-strength stacking and splicing, no asbestos components, small heat loss and low energy consumption.

2. Heating on three sides (left, right and bottom side) to achieve good uniformity in the furnace.

3. The silicon carbide bottom plate covers and protects the bottom of the furnace, which has high mechanical strength, good thermal conductivity, and provides horizontal load bearing.

4. The trolley at the bottom moves smoothly and without impact.

5. The material is loaded from bottom, and the workbench can be moved.

6. Can be customized according to process requirements.

7. Advanced control and adjustment system, precise temperature control.

8. There is an automatic flip-type exhaust port on the top of the furnace to realize the debinding of materials.

9. The furnace top circulation fan is selected to increase the uniformity of the temperature field in the furnace.

10. Furnace temperature and air rapid cooling control unit can be selected to realize rapid cooling within the furnace

temperature of 400°C.

11. Optional manual and automatic air intake control unit.

Mechanical hydraulic lifting furnace door

Auto lifting upwards door or door integrated with car bottom the operation button on the separate control box

M

ain Features

High standard, high quality

Heating Element

High quality HRE alloy resistance wire,Excellent temperature uniformity;

Temp Controller

It can be programmed with 30 sections, and RS485 communication interface and communication software can be selected to realize remote control and data recording of the furnace;

Voltmeter And Ammeter

Accurately measure the current intensity in the circuit, with precision standard and clear scale;

Henan Sante Furnace Technology Co., Ltd. is a high-tech enterprise located in Luoyang area of Henan﹒China Free Trade Zone.SAFTHERM products cover 1000℃/1200℃/1300℃/1400℃/1600℃/1700℃/1800℃ Box furnace, Tube furnace, Vacuum furnace, High Temperature Furnace, 2000℃ Ultra-High Temperature Furnace, Dental furnace, Industrial chamber furnace, elevator furnace, Intelligent mobile car bottom furnace, Smelting furnace and so on.

Our goal is to continuously meet the various demands for various kinds of high temperature heating treatment lab furnaces and to be the world first-class enterprise with providing excellent service and high-quality products for our cooperation partners!

Henan Sante Furnace Technology Co., Ltd.

Email:

caleb.li@saftherm.com

Hot Searches