Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

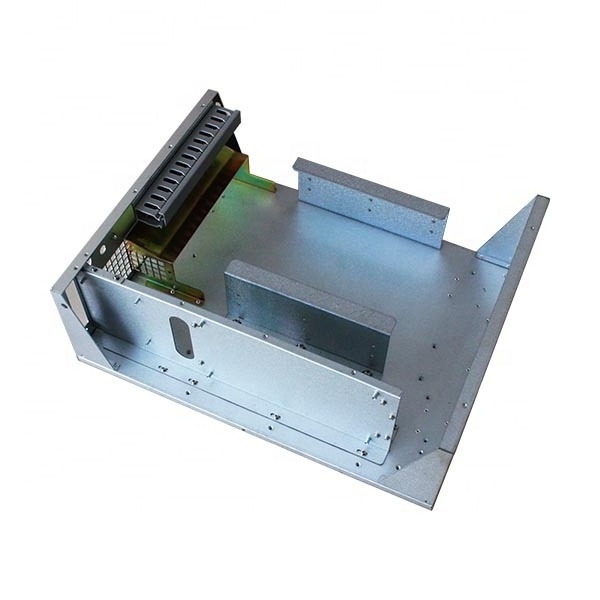

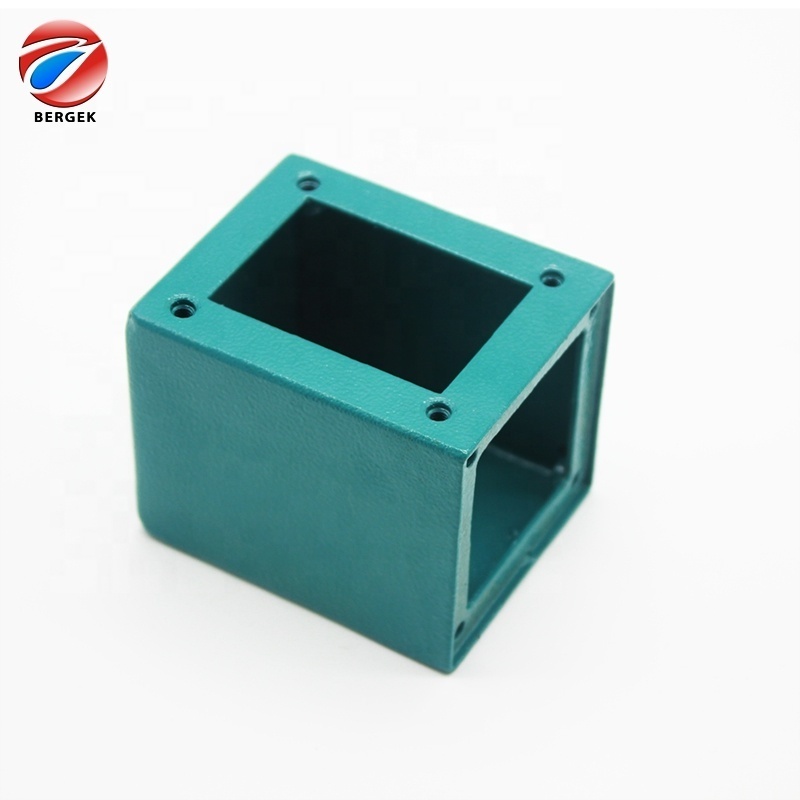

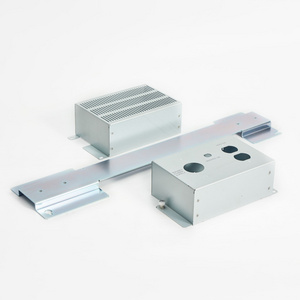

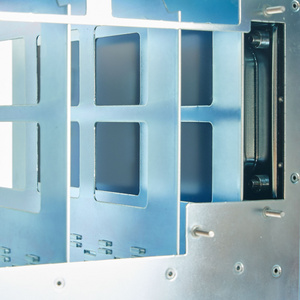

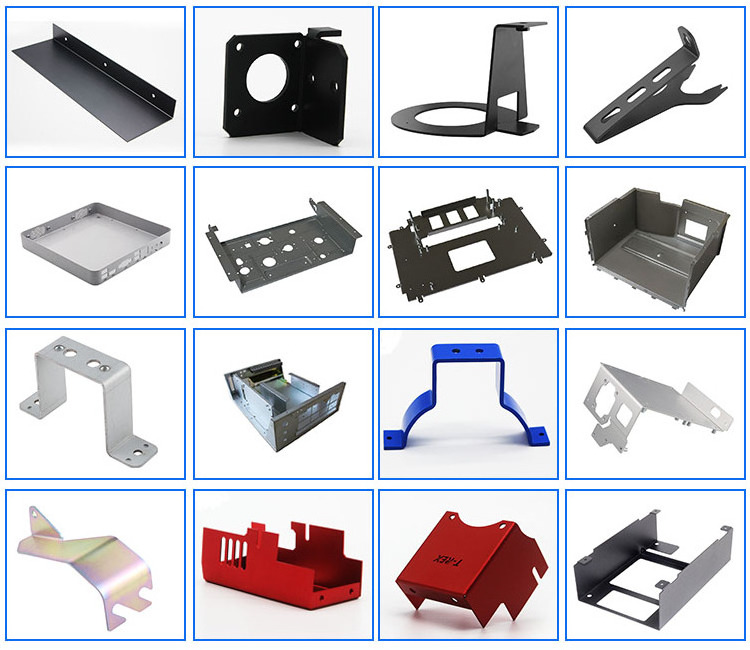

custom sheet metal fabricating

-

Material:

-

Aluminum. Iron. Stainless steel. Brass. Copper

-

Application:

-

Auto. motoclycle, vehicle,

-

Surface treatment:

-

Power coating, Polising, anodized, Electroplating

-

Process:

-

Stamping, punching, bending , welding

-

Service:

-

Customized OEM

-

Name:

-

Custom Sheet Metal Parts

-

Color:

-

Customized Color

-

Place of origin:

-

guangdong, china

-

Lead time:

-

7-25 days

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Bergerk or Custmized

-

Model Number:

-

stamping part

-

Product name:

-

custom sheet metal fabricating

-

Material:

-

Aluminum. Iron. Stainless steel. Brass. Copper

-

Application:

-

Auto. motoclycle, vehicle,

-

Surface treatment:

-

Power coating, Polising, anodized, Electroplating

-

Process:

-

Stamping, punching, bending , welding

-

Service:

-

Customized OEM

-

Name:

-

Custom Sheet Metal Parts

-

Color:

-

Customized Color

-

Place of origin:

-

guangdong, china

-

Lead time:

-

7-25 days

|

Product Name

|

|

|

|

|

||||

|

Tolerance

|

+/-0.01mm, 100% QC quality inspection before delivery, can provide quality inspection form.

|

|

|

|

||||

|

Processings

|

Laser Cutting, Precision Stamping, CNC Bending, CNC Milling, CNC Turning, Threading, Riveting, Drilling, CNC Punching, Die Casting, Laser Welding, etc.

|

|

|

|

||||

|

MOQ

|

Low MOQ Start 1 Pcs ( No need mold cost ), Many Customers found us make prototype product to save Investment Funds for Pre-R&D and Market Testing.

|

|

|

|

||||

|

Sample Cost

|

Free of Sample Cost. Normally is USD 35~110 per Style Of Special Design We Need Sample Charge, Can Refund when You Have Official Bulk Order.

|

|

|

|

||||

|

Delivery Time

|

1-25 days after order with prepayment based on products structure and quantity

|

|

|

|

||||

|

|

|

|

|

|||||

|

Stainless Steel

|

SS201,SS301,SS303, SS304, SS316, SS416 etc.

|

|

|

|

|||

|

Steel

|

mild steel, Carbon steel, 4140, 4340, Q235, Q345B, 20#, 45#,etc.

|

|

|

|

|||

|

Brass

|

HPb63, HPb62, HPb61, HPb59, H59, H68, H80, H90 etc.

|

|

|

|

|||

|

Copper

|

C11000,C12000,C12000, C36000 etc.

|

|

|

|

|||

|

Aluminum

|

AL6061, Al6063, AL6082, AL7075, AL5052, A380 etc.

|

|

|

|

|||

|

Iron

|

A36, 45#, 1213, 12L14, 1215 etc.

|

|

|

|

|||

|

Plastic

|

ABS, PC, PE, POM, Nylon, PP, Peek, etc.

|

|

|

|

|||

|

Stainless Steel

|

Polishing, Passivating, Sandblasting, Laser engraving

|

|

Steel

|

Zinc plating, Oxide black, Nickel plating, Chrome plating, Carburized, Powder Coated

|

|

Aluminum parts

|

Clear Anodized, Color Anodized, Sandblasted Anodized, Chemical Film, Brushing, Polishing

|

|

Plastic

|

Plating gold (ABS), Painting, Brushing (Acrylic), laser engraving

|

|

Agricultural equipment

|

Computing equipment

|

Automobile industry

|

Armament

|

|

Medical / dental instruments

|

Measuring instruments

|

Miscellaneous equipment

|

Textile equipment

|

|

Pharmaceutical industry

|

Pumps and general connections

|

Petrochemical industry

|

Safety equipment

|

|

Industrial valves

|

Fixing and movable equipment

|

Pharmaceutical industry

|

General machinery

|

|

Orthopedic implants

|

Food and beverage processing

|

Instrumentation equipment

|

Sanitary fittings

|

5, Quality Control

1) Checking the raw material after they reach our factory------- Incoming quality control ( IQC)

2) Checking the details before the production line operated

3) Have a full inspection and routing inspection during mass production---In-process quality control(IPQC)

4) Checking the goods after they are finished---- Final quality control(FQC)

5) Checking the goods after they are finished-----Outgoing quality control(QC)

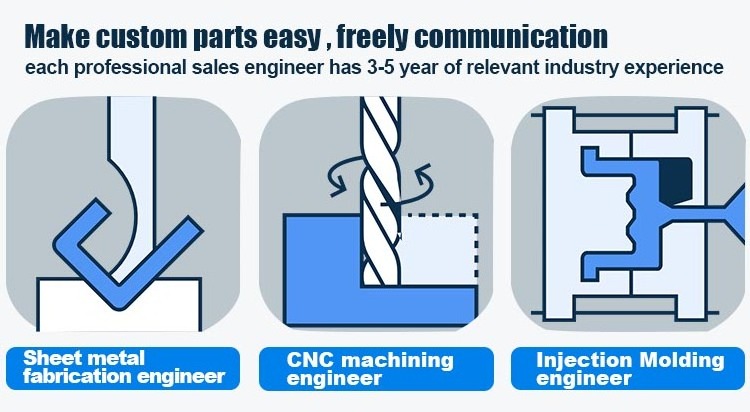

The leader of our enterprise is an Engineer,

As long as you give us the functionality, performance, or even the idea of the product, we can change the product from the idea to reality. Welcome to consult immediately

Corporate philosophy: All problems end with us

On-site shooting process diagram 々々↓↓↓↓

Q: Is your organization committed to the concept of total quality management?

A: Yes, no matter in laser cutting, bending, or CNC machining, the workers will conduct the first sample inspection and random inspection during the processing to ensure the quality of the products.

Q:

How many checks are performed on a project?

A:

Usually, products will go through the following four inspections: incoming inspection, production first inspection, sampling inspection, and pre-shipment inspection. Among them, sampling inspection will be conducted multiple times

Q:Will you be able to work with our engineering team to review drawings and provide quick, estimated pricing for desired changes?

A:

Yes, our engineers respond very quickly. If there is anything to be modified in the product, we can offer you a new price as soon as you tell us.

Q :

What's kinds of information you need for a quote?

A :

Kindly please provide the product drawing in PDF,and will be better you can provide in .dwg / .stp / . iges / .stl , Send drawing

Q:Is the material ROHS compliant?

A:

Yes

Q:Will your company sign an NDA?

A:

Yes

The final interpretation is owned by our company