- Product Details

- {{item.text}}

Quick Details

-

Mold Height(mm):

-

125 - 300 mm

-

Ejector Number:

-

According to model

-

Ejector Stroke(mm):

-

125 mm

-

Ejector Force(kN):

-

117 kN

-

Theoretical Shot Volume(cm³):

-

12 cm³

-

Injection Rate (g/s):

-

200 g/s

-

Injection Weight (g):

-

50 g

-

Screw Speed (rpm):

-

0 - 200 rpm

-

Screw diameter (mm):

-

18 mm

-

Weight (KG):

-

225 kg

-

Place of Origin:

-

Fujian, China

-

Open Stroke(mm):

-

75 mm

-

Model Number:

-

According to model

-

Brand Name:

-

OLLITAL

-

Power (kW):

-

0.7 kW

-

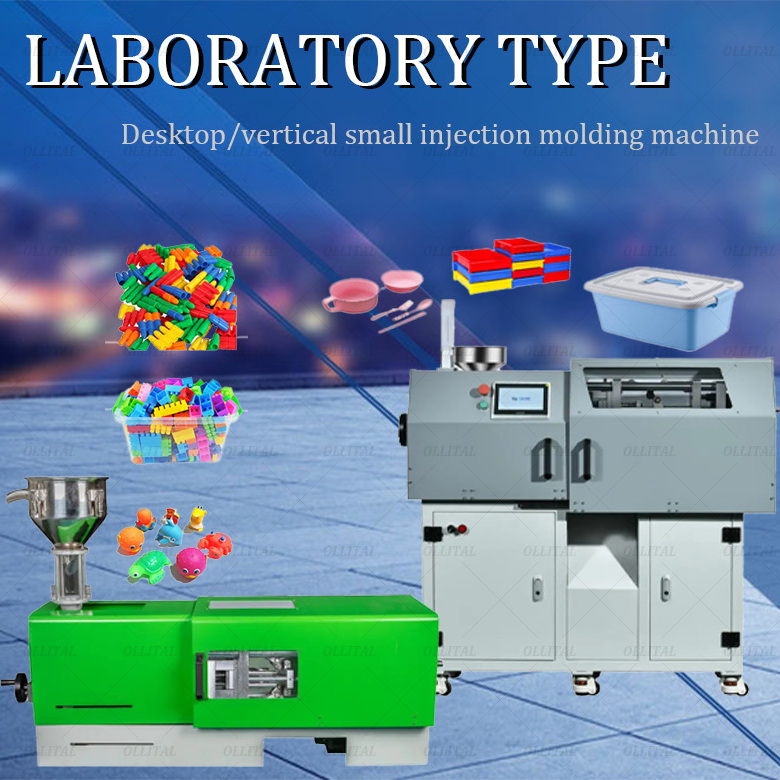

Product name:

-

Plastic Injection Moulding Machine

-

Function:

-

Plstic Injection Molding Machinery

-

Keyword:

-

Desktop Molding Machine Injection

-

Application:

-

Produce Plastic Products

Quick Details

-

Distance between Tie Bars(Width)(mm):

-

22mm

-

Distance between Tie Bars(Height)(mm):

-

22mm

-

Plasticizing Capacity(g/s):

-

According to model

-

Mold Height(mm):

-

125 - 300 mm

-

Ejector Number:

-

According to model

-

Ejector Stroke(mm):

-

125 mm

-

Ejector Force(kN):

-

117 kN

-

Theoretical Shot Volume(cm³):

-

12 cm³

-

Injection Rate (g/s):

-

200 g/s

-

Injection Weight (g):

-

50 g

-

Screw Speed (rpm):

-

0 - 200 rpm

-

Screw diameter (mm):

-

18 mm

-

Weight (KG):

-

225 kg

-

Place of Origin:

-

Fujian, China

-

Open Stroke(mm):

-

75 mm

-

Model Number:

-

According to model

-

Brand Name:

-

OLLITAL

-

Power (kW):

-

0.7 kW

-

Product name:

-

Plastic Injection Moulding Machine

-

Function:

-

Plstic Injection Molding Machinery

-

Keyword:

-

Desktop Molding Machine Injection

-

Application:

-

Produce Plastic Products

↓ ↓ ↓

A variety of styles for you to choose from. There is always one suitable for you!

↓ ↓ ↓

-

Efficient production

: Injection molding machines can achieve high-speed, continuous production of plastic products, greatly improving production efficiency.

-

Precise injection molding

: It has a precise injection molding control system that can accurately control the injection volume, pressure and speed of plastic materials, ensuring the dimensional accuracy and quality stability of the product.

-

Diversified design

: The injection molding machine can replace molds according to different production needs and produce plastic products of various shapes, sizes and colors, with strong production flexibility.

-

Energy saving and environmental protection

: Some injection molding machines adopt advanced energy-saving technologies, such as frequency conversion control, energy-saving motors, etc., which can reduce energy consumption and meet the requirements of energy saving and environmental protection.

-

Easy operation

: The operation interface of the injection molding machine is usually designed to be simple and intuitive, easy to operate, and the operator can quickly get started and start production.

-

Safety

: The injection molding machine has multiple safety devices, such as safety doors, emergency stop buttons, overload protection, etc., to ensure the safety of operators and equipment.

-

Reliable and stable

: The injection molding machine uses high-quality mechanical and electrical components, has a stable structure, reliable operation, low failure rate, and can work stably for a long time.

-

High degree of automation

: Advanced injection molding machines are equipped with advanced automation control systems, which can achieve fully automated production and improve production efficiency and product consistency.

|

Machine type

|

OLT-XPM-12

|

OLT-XPM-12X

|

OLT-XPM-17

|

|||

|

Machine size

|

1300x400x450mm

|

1400x475x1200mm

|

1400x475x550mm

|

|||

|

Machine weight

|

145KG

|

180KG

|

225KG

|

|||

|

Screw diameter

|

18mm

|

18mm

|

22mm

|

|||

|

Voltage

|

220V

|

220V

|

220V

|

|||

|

Nozzle diameter

|

3mm

|

3mm

|

3mm

|

|||

|

Product weight

|

30g

|

30g

|

40g

|

|||

|

Temperature range

|

0~400℃

|

0~400℃

|

0~400℃

|

|||

|

Clamping force

|

12T

|

12T

|

15T

|

|||

|

Mold opening stroke

|

75mm

|

85mm

|

125mm

|

|||

|

Corinthian distance

|

120*120mm

|

120*120mm

|

195*195mm

|

|||

|

Mold installation dimensions

|

200x125x150mm (excluding die)

|

200x125x150mm (excluding die)

|

195x250x170mm (excluding die)

|

|||

|

Power consumption

|

0.7kw

|

0.7kw

|

0.8kw

|

|||

|

Heating power

|

1kw

|

1kw

|

1kw

|

|||

|

Monitor

|

Touch screen

|

Touch screen

|

Touch screen

|

|||

|

Control System

|

PLC

|

PLC

|

PLC

|

|||

|

Applicable materials

|

Engineering plastics PP, PE, PA6, PS, PEI, FMMA, PVC, ABS, TPU, FET, etc.

|

|

|

|||

|

|

|

|

||||

* All models can be customized according to drawings and needs.

Contact an engineer

today to learn about the most suitable and cost-effective solution!

①

Intelligent control

②

Multi-stage thermostatic control

③

Crankshaft clamping

Efficient and stable, large clamping force, flexible adjustment, easy operation, safe and reliable, wear-resistant and corrosion-resistant and easy to maintain. This mechanism can quickly and reliably complete the locking operation of the mold, improve production efficiency, and ensure product quality. It is an important mold locking device in the injection molding machine.

④

Dual servo energy-saving motors

The dual servo energy-saving motor has the characteristics of high efficiency and energy saving, precise control, quick response, strong stability, multi-functionality, strong adjustability, environmental protection, energy saving and easy maintenance. This kind of motor can effectively reduce energy consumption, improve production efficiency and product quality, and at the same time meet environmental protection requirements. It is an important energy-saving equipment in injection molding machines.

Q1. What is your products range?

•

OLLITAL

is a high-tech enterprise focusing on R&D and specializing in the production of industrial machinery,

dry ice production machinery

,

dry ice cleaning machinery

,

laboratory biological equipment

,

biological fermentation equipment

,

laboratory reaction equipment

and

other

fields. (

M

ore products

)

Q2. Are you trading company or manufacturer?

• We are a professional manufacturer of

Laboratory, industrial equipment

, and we have our own factory.

Q

3. Do you provide samples? Is it free?

• Yes, we could offer the sample. Considering the high value of our products, the sample is not free, but we will give you our best price including shipping cost.

Q4.

Do you have warranty

?

• Yes, we offer 1 year warranty for the spare part.

Q5. How long is your delivery time?

• Generally it is within 7 working days after receiving the payment if the goods are in stock. Or it is 15 working days if the goods are not in stock, depending on order quantity.

Q6. What is your terms of payment?

• Payment≤15,000USD, 100% in advance. Payment≥15,000USD, 70% T/T in advance, balance before shipment.

(If you are worried about the payment security of your first order, we suggest that you can place a trade assurance order through Alibaba. If we cannot meet the agreed delivery time, you will get 100% of your payment refund. )

Email:

kevin

@ollital.com Jack@ollital.com

WhatsApp:+8615960821529 +8618030169616

Alibaba:

https://

xmollital.en.alibaba.com

Official website:www.ollital.com

Dry Ice cleaning website: www.ollital-cleaningmachines.com

Add: Room 416, No. 39, Xinchang Road, Haicang District, Xiamen City, Fujian Province, China

Official website:www.ollital.com

Dry Ice cleaning website: www.ollital-cleaningmachines.com

Add: Room 416, No. 39, Xinchang Road, Haicang District, Xiamen City, Fujian Province, China

This is the product you need!

"

Contact an engineer

" immediately to provide you with the most suitable solution!

Hot Searches